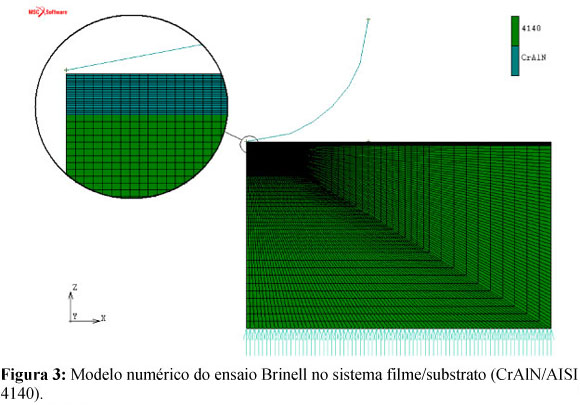

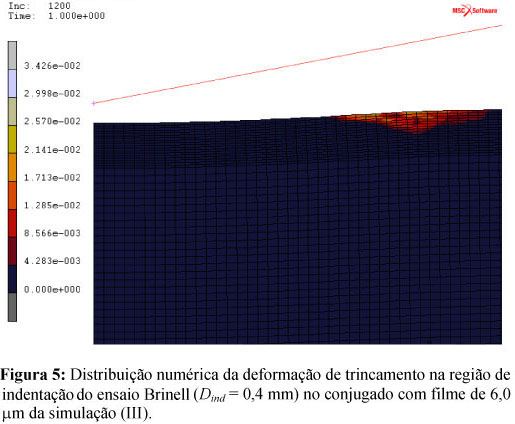

The aim of the present study was simulate the cycle of indentation test with spherical indenters in a system composed of thin surface coating deposited on a metallic substrate through PVD process by finite element models. Recent studies suggest that the indentation technique could be used as a tool to evaluate mechanical properties of thin films, as well as to determinate the fracture process in systems that combine high hardness coatings, like stainless steel substrates, in tribological applications. However, the implementation of this technique to evaluate the behaviour of these systems and their results, have still been doubts in the scientific community. Because of these uncertainties in the analysis of indentation test, the use a numerical methodology capable of evaluating the fields of stresses and deformation during the indentation cycle can help in a more secure interpretation of this testing. Nevertheless, the use of the numerical methodology to evaluate the indentation test in thin surface coatings also has had problems mainly due to the difficulty in implementing failures models, especially in determinating the behaviour for the interface between the coating and the substrate. Finally, it was used a numerical cracking model to study the mechanisms of nucleation and growth of cracks that occur in these films during indentation test.

Indentation Testing; Finite Element; Fracture; Cracking Model