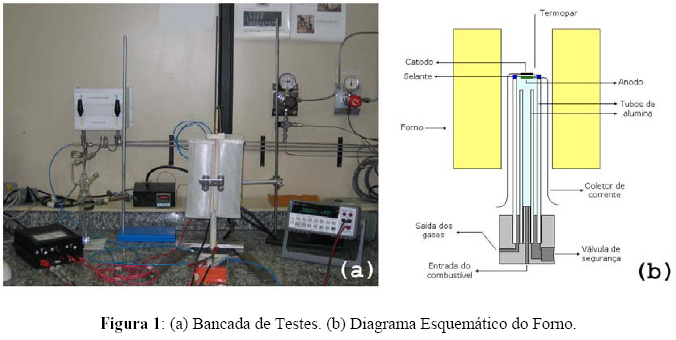

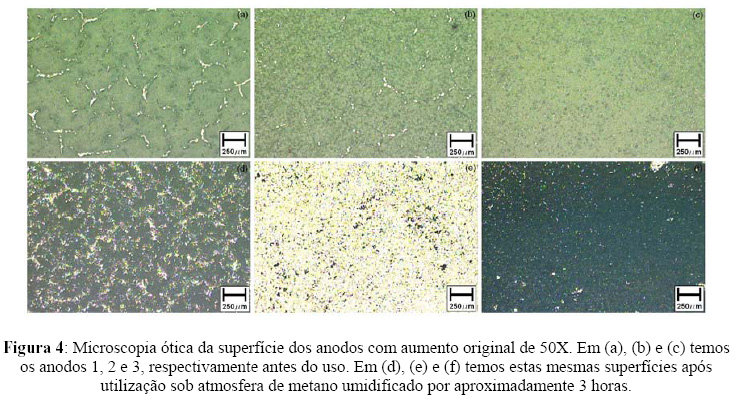

The main objective of this paper is to study and develop a fabrication method of ceramic suspensions for anodes of SOFC that could be printed on plane electrolytes by screen-printing, which is a simple technique, and of easy scalability, as well as being a low cost method that produces components with good electrocatalytic properties. The ceramic suspensions for the anodes were manufactured with a nickel oxide prepared in the GECAT’s laboratory at UFBA, and with commercial YSZ, GDC and dispersant, and were then processed in a planetary ball mill. Two kinds of YSZ were used for the anode, one with 4.3%mol of yttria and mean particle size of 0.5 µm and another with 9.3%mol of yttria and mean particle size of 8 µm. Besides, another suspension was fabricated with the 9,3%mol of yttria zirconia adding 5%wt of GDC. Commercial electrolytes of 8%mol YSZ were used as support and for the cathode a commercial ceramic suspension of LSM of stoichiometry La0,8Sr0,2MnO3 was used. The cells were tested at 950°C under hydrogen and methane atmospheres, so the electrochemical performance of the electrodes could be determined through graphics of potential and power density versus current density. Optical and scanning electron microscopy analyses were carried out to determine the morphology and the integrity after use of the electrodes.

Anode; YSZ; GDC; ceramic suspensions; screen-printing; SOFC