ABSTRACT

In this study, eight different manure treatment plants were monitored. The plants were four on-farm and four centralized treatment plants, all of them at full-scale level. Assessment includes a total of seven pre-treatment and process units as follows: mechanical separation, with and without coagulant and flocculant addition, pasteurization, nitrification-denitrification, anaerobic digestion, and composting. The plants are located in nutrient surplus areas of three European Member States (Spain, Italy and Denmark), the majority of these areas being Nitrate Vulnerable Zones (NVZ). Results presented herein are data collected over a six-month period and comprise performance data of the treatment plants, pathogen indicators (E.coli and Salmonella) and greenhouse gas (GHG) emissions data under two scenarios: 1) the baseline scenario and 2) the treatment plant scenario. The assessment includes GHG emissions of the storage facilities, transportation, and subsequent intermediate storage, electric consumption, electric production, composting, and land application. All treatment plants studied generated a significant reduction in GHG emissions (between 53 and 90 %) in comparison to the baseline scenario. Organic matter and total solids (TS) content in manure were also greatly reduced, with values ranging between 35-53 % of chemical oxygen demand (COD) and, 24-61 % of TS for anaerobic digestion (AD) treatment plants, 77-93 % COD and 70 % TS in the case of AD combined with nitrogen (N)-removal unit plants. Nitrogen concentrations were also greatly reduced (between 65-85 %) total Kjeldahl nitrogen (TKN) and 68-83 % ammonium (NH4+-N)) in plants with N-removal units.

Greenhouse gas reduction; manure treatment technologies; anaerobic digestion; composting; nitrification-denitrification

Introduction

In nutrient-saturated areas, nutrient management planning is necessary if pollution is to be avoided which will consist of a set of actions designed to ensure adequate manure production to meet the demand for quality products from agricultural soils (Teira-Esmatges and Flotats, 2003Teira-Esmatges, M.R.; Flotats, X. 2003. A method for livestock waste management planning in NE Spain. Waste Management 23: 917-932.). This set of actions must include minimal on-site limitation of components’ outflow rates, soil fertilization planning, economical cost, and feasible treatment analyses applicable to the improvement of manure management (Flotats et al., 2009). However, in a number of geographical areas where there is a surplus of nutrients, different strategies and a high level of planning are necessary. In these cases, the application of manure treatment technologies is presented as a good option. There are different technological options for treating manure; therefore, the decision, with respect to the scale of treatment and technological complexity, will depend on aspects such as the size of the facility, the depuration level required, organic matter (OM) and removal of nutrients, the need to produce energy, and the installation and maintenance costs of the plant amongst others (Petersen et al., 2007Petersen, S.O.; Sommer, S.; Béline, F.; Burton, C.; Dach, J.; Dourmad, J.; Leip, A.; Misselbrook, T.; Nicholson, F.; Poulsen, H.D.; Provolo, G..; Sørensen, P.; Vinneras, B.; Weiske, A.; Bernal, M.P.; Böhm, R.; Juhász, C.; Mihelic, R. 2007. Recycling of livestock manure in a whole-farm perspective. Livestock Science 112: 180-191.). To support the decision-making process, it is necessary to unify criteria for the evaluation of different manure treatment systems and management schemes; this is one of the objectives of the MANEV project (Evaluation of manure management and treatment technology for environmental protection and sustainable livestock farming in Europe), a European project of large-scale demonstration framed within the LIFE + Environment Policy and Governance program. Eight partners from four European countries are involved in the project, covering eight regions with high livestock production and nutrient surplus, as well as high population density.

This study addresses the results from eight manure treatment plants monitored over a six-month period. The results presented herein include the performance data of the plants, pathogen indicators (E. coli, Salmonella), as well as the estimation of greenhouse gas (GHG) emission reduction arising from the installation of manure treatment plants as an alternative to conventional manure storage (baseline scenario vs. treatment plant scenario). Each case study consisted of different process units that are shown in Figures 1-8 8 Marshal of the Warmińsko-Mazurskie Voivodeship Olsztyn Poland Office of the Marshal of the Warmińsko-Mazurskie Voivodeship, Emilii Plater 1 – 10-562 – Olsztyn – Poland. . Greenhouse gas emissions were quantified following the guidelines proposed by the Intergovernmental Panel on Climate Change (IPCC) together with monitoring information collected during the study of the full-scale treatment plants.

− Diagram of an on-farm treatment plant for swine manure based on solid-liquid separation and nitrification-denitrification of the liquid fraction in Castilla y León, (Spain) (Case 1). Data correspond to average values; standard deviation is included. Flow (Q), total solids (TS), volatile solids (VS), chemical oxygen demand (COD), total Kjeldahl nitrogen (TKN), ammonium (NH4+-N), total phosphorus (TP).

Materials and Methods

Common evaluation and monitoring protocol

One of the most important activities was to define a framework to unify the methodology for the assessment of different manure management technologies with the objective of obtaining comparable data from the monitored systems. This evaluation included environmental, agronomic, energetic, economic, social, sanitary and legislative criteria and, for this purpose, a group of indicators, parameters, evaluation and analysis procedures were described. As a result, a Common Evaluation and Monitoring Protocol (CEMP) was established as a guideline. The scope of the assessment was limited to manure management. The boundaries of the system were between the storage tank of manure in the farm and the cropland fertilization.

Samples were collected at regular frequency intervals from different sampling points throughout the treatment processes, allowing for evaluation of the performance of each treatment plant in terms of removal of chemical oxygen demand (COD), total solids (TS), volatile solids (VS), total Kjeldahl nitrogen (TKN), ammonium (NH4+-N), total phosphorus (TP) and metals (Cu and Zn). These parameters were analyzed in accordance with APHA Standard Methods (2005)American Public Health Association [APHA]. 2005. Standard Methods for the Examination of Water and Wastewater. 21ed. American Public Health Association, Washington, DC, USA.. Removal of pathogen agents (E. coli and Salmonella) was also determined. In addition, methane (CH4) content in biogas produced during the anaerobic digestion processes was also evaluated.

Environmental monitoring was also carried out to evaluate the direct consequences of the implementation of the manure treatment plants as pertains to GHG emissions. In particular, the GHG reduction, arising from the installation of a manure treatment plant as an alternative to conventional manure storage, was estimated. Carbon dioxide (CO2), CH4, and nitrous oxide (N2O) emissions in the storage tank (baseline scenario) and in the treatment plants were quantified using the guidelines proposed by the Intergovernmental Panel on Climate Change (IPCC, 2006Intergovernmental Panel on Climate Change [IPCC]. 2006. IPCC guidelines for national greenhouse gas inventories. Available at: http://www.ipcc-nggip.iges.or.jp/public/2006gl/index.html [Accessed Jun. 13, 2013]

http://www.ipcc-nggip.iges.or.jp/public/...

), together with monitoring information collected during the study of the treatment plants according to the CEMP.

Carbon dioxide production from manure was not taken into account in this study, since this was considered part of the so-called short-term carbon cycle, i.e. resulting from recent CO2 uptake by crops (López-Ridaura et al., 2009López-Ridaura, S.; Werf, H. van der; Paillat, J.M.; Le Bris, B. 2009. Environmental evaluation of transfer and treatment of excess pig slurry by life cycle assessment. Journal of Environmental Management 90: 1296-1304.). However, CO2 emissions from fossil energy use were taken into account, considering non-renewable energy use incurred during both transportation of manure and land application as well as electric power use during the treatment process. Fuel consumption, distance travelled and electric power use were estimated for each case study. Emission factor parameters involved in calculating CO2, CH4 and N2O emissions due to transportation were based on the method proposed by the IPCC Guidelines (2006). Emissions were calculated using a Lower Heating Value (LHV) of 42.6 MJ kg−1 (López-Ridaura et al., 2009López-Ridaura, S.; Werf, H. van der; Paillat, J.M.; Le Bris, B. 2009. Environmental evaluation of transfer and treatment of excess pig slurry by life cycle assessment. Journal of Environmental Management 90: 1296-1304.) and a fuel density of 830 kg m−3. The emission factor used in the case of electrical consumption was 0.206 kg CO2 kW h−1, corresponding to the Spanish electricity mix in 2010 (OCCC, 2013Oficina Catalana del Cambio Climático [OCCC]. 2013. Methodology for the estimation of the electrical mix for the Catalan Office for Climate Change. Available at: http://canviclimatic.gencat.cat/web/.content/home/redueix_emissions/factors_emissio_associats_energia/150213_Nota-metodologica-mix_cast.pdf [Accessed Jan. 8, 2016]

http://canviclimatic.gencat.cat/web/.con...

). Methane was also emitted during the storage stage in the treatment plants and the baseline scenarios; and N2O during the nitrification-denitrification (NDN) processes, the storage of end products and land application. Methane and N2O emissions in both scenarios were calculated following the IPCC Guidelines (IPCC, 2006Intergovernmental Panel on Climate Change [IPCC]. 2006. IPCC guidelines for national greenhouse gas inventories. Available at: http://www.ipcc-nggip.iges.or.jp/public/2006gl/index.html [Accessed Jun. 13, 2013]

http://www.ipcc-nggip.iges.or.jp/public/...

). Emissions of CH4 and N2O were expressed in terms of CO2 equivalents using approved Global Warming Potentials (25 for CH4 and 298 for N2O, respectively) (IPCC, 2006Intergovernmental Panel on Climate Change [IPCC]. 2006. IPCC guidelines for national greenhouse gas inventories. Available at: http://www.ipcc-nggip.iges.or.jp/public/2006gl/index.html [Accessed Jun. 13, 2013]

http://www.ipcc-nggip.iges.or.jp/public/...

).

All those emissions relating to the management of co-substrates or additional materials included in the processes were not assessed by our systems. These emissions were considered to belong to the systems of the process that generated them. Emissions relating to the complete treatment period throughout were assessed together with the evaluation of manure as part of the impact of treatment technology.

Results

Case 1: On-farm treatment plant based on solid-liquid separation and nitrification-denitrification of the liquid fraction for nitrogen removal in Castilla y León (Spain)

This facility processed the slurry generated in a farrow to finish system with approximately 300 sows (40 m3 d−1), having been in operation since 2006. The treatment was based on the NDN process. The objective of this on-farm technology was to transfer the surplus of nitrogen to the atmosphere by its conversion into N2 gas, as the farm did not have any land available for manure application. Figure 1 shows a diagram of the treatment plant. Well mixed raw manure was pumped from the homogenization tank to a screw press which had 0.5 mm openings followed by a coagulation-flocculation unit (Riaño and García-González, 2014Riaño, B.; García-González, M.C. 2014. On-farm treatment of swine manure based on solid-liquid separation and biological nitrification-denitrification of the liquid fraction. Journal of Environmental Management 132: 87-93.). The separated solid fraction was stored and exported from the farm whereas the liquid fraction was continuously fed into an NDN reactor with a volume of 350 m3 and where air was supplied using submerged aerators. The average loading rate of the system during the 6-month monitoring period was 0.13 kg N m−3 d−1 and the hydraulic retention time (HRT) was approximately 9.4 days (final lagoon not considered). Nitrification-denitrification reactor was followed by a settler (20 m3). The treated liquid fraction was piped to two lagoons (1300 m2) for storage. The whole system removed 94 % of COD, 80 % of TS and approximately 90 % of TKN, NH4+-N and TP (Table 1). Metals (copper and zinc) were reduced in the liquid fraction to non-detectable concentrations (< 1.0 mg L−1). As regards microbial removals, total concentration reductions of 2 log10 for Escherichia coli and 3 log10 for Salmonella were achieved (Table 2), the largest pathogen reduction occurring in the NDN reactor.

The farmer had assumed the operation of the system as a regular task, which had been identified as a major factor in the successful implementation of this particular manure treatment technology and represented an advantage of this system compared to other technologies (Flotats et al., 2009). The solid-liquid separation process reduced manure volume while increasing nutrient and organic concentration, thereby obtaining a high agronomic value solid fraction and cutting the transportation costs for land application compared to those incurred when transporting raw manure. Moreover, decreasing the organic carbon contained in the liquid fraction reduced aeration requirements in the subsequent NDN reactor, since oxygen was used more efficiently to convert NH4+-N into NO3--N rather than being used to break down organic compounds. The financial cost of the overall system was thus reduced (Vanotti et al., 2009Vanotti, M.B.; Szogi, A.A.; Millner, P.D.; Loughrin, J.H. 2009. Development of a second-generation environmentally superior technology for treatment of swine manure in the USA. Bioresource Technology 100: 5406-5416.). Finally, implementing the aerobic treatment for manure management led to a total annual greenhouse gas (GHG) emission reduction of approximately 65 % (Figure 9). This reduction was due mainly to the lower methane emissions occurring in the homogenization tank of the treatment plant compared to those emanating from storage in conventional anaerobic tanks. Likewise, emissions derived from transportation to receiving areas and land application itself were considerably lower than those estimated for the baseline scenario. The separated solid fractions in the treatment plant used as fertilizer present easier transportation and limit the losses of nutrient from emission and leaching due to slower release of nutrients (Cerutti et al., 2011Cerutti, A.K.; Bagliani, M.; Beccaro, G.L.; Giolli, F.; Balsari, P.; Bounous, G. 2011. Evaluation of the sustainability of swine manure fertilization in orchard through ecological footprint analysis: results from a case study in Italy. Journal of Cleaner Production 19: 318-324.).

− Comparison of greenhouse gas emissions between the baseline and the treatment plants’ scenario monitored.

Case 2: On-farm treatment plant based on anaerobic co-digestion and energy production in Cataluña (Spain)

The studied management system was an on-farm treatment plant with an anaerobic co-digestion reactor for energy recovery and a composting unit for the processing of the solid fraction. The plant was located in Girona (Spain), and treated 29,800 m3 yr−1 dairy manure and 6,200 t yr−1 of co-substrates.

The substrates were homogenized in a covered tank (200 m3) and fed to two serial mesophilic anaerobic digestion tanks, with a working volume of 2,100 m3 and 1,600 m3, respectively (Figure 2). The digestate was mechanically separated into two fractions; the solid fraction was composted in 4 trenches with forced aeration (346 m2), and the liquid fraction was stored in a 10,000 m3 pond. The average removal efficiency of the total solids was 64 %, while the removal efficiency of COD was 80 % (Table 1). The two end products obtained, digested liquid fraction and compost, accounted for 30,226 m3 yr−1 and 324 m3 yr−1, respectively (Figure 2). The liquid fraction was used for irrigation/fertilization of the crops nearby. The objective of the composting process was the production of a high quality compost to be sold in the fertilizer market. Thus, the compost produced, containing 4 % of the initial N and 10 % of the initial P, can be exported from the farm. The biogas obtained was used in a combined 347 kWe heat and power engine (CHP) and produced 3,960,370 kWh yr−1.

− Diagram of an on-farm treatment plant based on anaerobic codigestion and energy production in Cataluña, (Spain) (Case 2). Data correspond to average values; standard deviation is included. Flow (Q), total solids (TS), volatile solids (VS), chemical oxygen demand (COD), total Kjeldahl nitrogen (TKN), ammonium (NH4+-N), total phosphorus (TP).

Most of the emissions under the treatment plant scenario were produced in the final storage pond (81 % of CH4), but compared with the baseline scenario, the new management system resulted in a reduction of 65 % of the GHG emissions (Figure 9).

Case 3: On-farm treatment plant based on energy production to manage nitrogen content through the SHARON-SBR process in Emilia-Romagna (Italy)

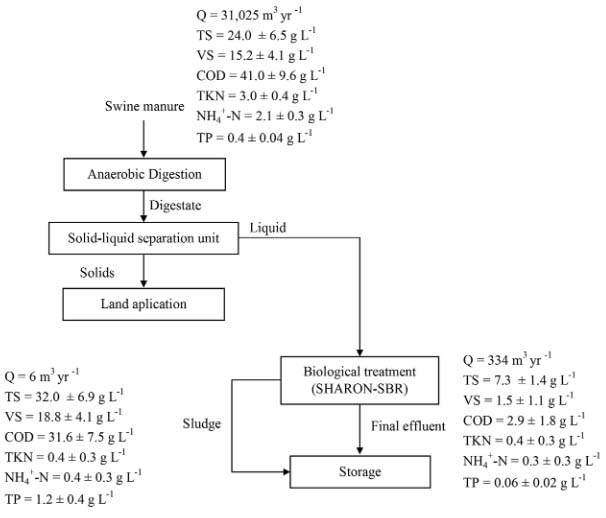

The study was carried out in a closed cycle pig farm with 975 sows and 950 t of live weight. The daily average production of pig slurry was 85 m3. Slurry treatment management in the livestock farm was by AD and aerobic biological treatment (SHARON-SBR), as shown in Figure 3.

− On-farm treatment plant based on energy production to manage nitrogen content through the SHARON-SBR process in Emilia-Romagna, (Italy) (Case 3). Data correspond to average values; standard deviation is included. The daily average production of pig slurry was 85 m3. The anaerobic digestion unit treated all volume, whereas only 1 m3 d−1 of the 85 m3 d−1 was treated by AD followed by SBR pilot plant. Flow (Q), total solids (TS), volatile solids (VS), chemical oxygen demand (COD), total Kjeldahl nitrogen (TKN), ammonium (NH4+-N), total phosphorus (TP).

Anaerobic digestion of raw pig slurry was carried out in a mesophilic completely stirred reactor on a farm scale with a volume of 1,780 m3 and HRT of 21 days. The biogas produced (580 m3 d−1 and CH4 content of 67 %) was used by a CHP with maximum electric power of 85 kWe. The daily average gross electric production was 1,117 kWh with an average of 15 operating hours per day.

The SHARON process was carried out in an SBR (Sequencing Batch Reactor) pilot farm scale plant. This aerobic reactor was fully insulated and it had a process volume of about 3 m3 and was able to handle 1,000 dm3 digestate daily, thus only 1 m3 d−1 of the 85 m3 d−1 was treated by AD followed by SBR. The sequencing batch reactor was a cylindrical tank with a radius of 0.66 m with a useful hydraulic head of 2.23 m. The phases of the aerobic treatment included loading, reaction (with phases of aeration and mixing), sedimentation, sludge output and stasis. In one day, the system provided a succession of four cycles, lasting approximately 6 hours each.

To get the nitrosation stopped to nitrite and denitrification of nitrite to N2 gas, the growth of AOB bacteria (ammonium oxidizer bacteria) should be encouraged, at the expense of NOB bacteria (nitrite oxidizer bacteria). This was possible when the AOB growth rate was greater than that of NOB, exploiting the different sensitivities of these two bacterial groups. The process parameter setting of the SBR that allowed for maximum removal efficiency during monitoring activity were as follows: temperature 35-36 °C (heat recovered from CHP), pH 7.5 – 8.3, dissolved oxygen 1.2 mg L−1, HRT 2.6 day, SRT (solid retention time) 25-30 days and volatile suspended solid (VSS) concentration of 12-13 g L−1 inside the reactor (with a VSS/total suspended solid (TSS) ratio of 0.70-0.75).

The removal efficiency of the whole treatment system is shown in Table 1. The average total nitrogen removal efficiency was 56 % (considering Total Nitrogen content as the sum of TKN, nitrate NO3- and nitrite NO2- in the effluent from SBR, while nitrate and nitrite are absent from influent pig slurry). The effluent was stored in a farm lagoon for land spreading destination. Total emission reduction, in t CO2 eq m3 with the treatment plant scenario of pig slurry compared to baseline scenario, is 62 %, shown in Figure 9. The GHG emission reduction is due, to a large extent, to the recovery of the biogas to produce heat and electrical power and also to the very low methane production potential and low N content of treated effluent in final storage. On the other hand, however, SBR aerobic treatment produces N2O emissions.

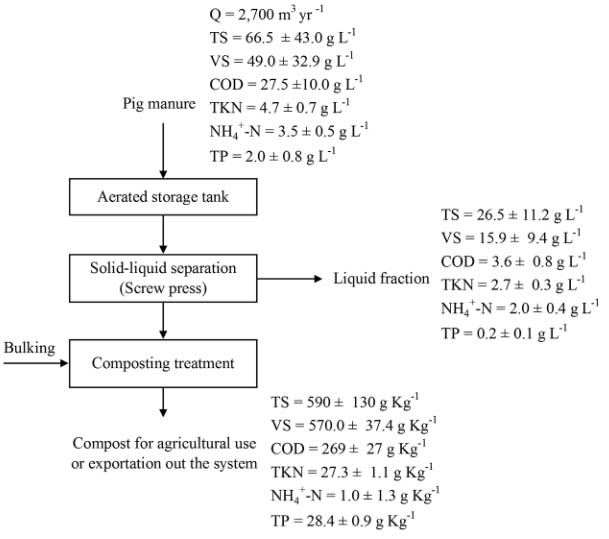

Case 4: On-farm composting of the manure solid fraction in Murcia (Spain)

The scenario selected for monitoring the composting technology was a pig farm (500 sows and 1,500 piglets) equipped with a solid-liquid slurry separation system (Figure 4). The infrastructure included the following: an aerated pig slurry storage tank, the mechanical solid-liquid separation by screw-press (mechanical separator without flocculants), and a solid-surface area next to the separator for the storage of the solid fraction and for the composting pile, with adequate inclination for collecting any leaching in the pig slurry storage tank. The separated liquid fraction was aerobically treated before being used for fertirrigation in citrus orchards (outside the scope of the study).

− Diagram of an on-farm composting plant of solid fraction of manure in Murcia, (Spain) (Case 4). Data correspond to average values; standard deviation is included. Flow (Q), total solids (TS), volatile solids (VS), chemical oxygen demand (COD), total Kjeldahl nitrogen (TKN), ammonium (NH4+-N), total phosphorus (TP).

The monitoring of composting technology in the pig farm was carried out by sampling the materials at different points in the process: raw pig slurry, liquid fraction, solid fraction, and compost produced from the solids. Two composting methodologies were monitored: 1) based on solid fraction stored for up to one month after mechanical separation, mixed with cereal straw as bulking agent; 2) using solid fraction freshly prepared (up to 3 days) mixed with cotton gin waste as bulking agent. The piles were turned mechanically 3 and 5 times during the biooxidative phase, after which the materials were left to mature over 1.5 months.

The solid-liquid separation concentrated the OM, organic-N, P, K and micronutrients (Cu and Zn) from the pig slurry in the solid fraction, while NH4+-N was distributed in both solid and liquid fractions. Composting was developed more intensively in the second methodology, using a freshly separated solid fraction mixed with cotton gin waste, with a quick development of thermophilic temperatures within the first week, lasting for 70 days. However, the first strategy required almost 3 weeks for temperatures to reach 40 ºC and above, and it occurred only after the first turning and addition of fresh pig slurry as inoculum. The excess of moisture in the pile prepared with cereal straw (79 %), together with the use of partially degraded solid fraction during its storage time (1 month) were responsible for the low temperature development (only 14 days at < 40 ºC).

During composting, the organic matter is degraded and water is evaporates due to the high temperatures of the material (Bernal et al., 2009Bernal, M.P.; Alburquerque, J.A.; Moral, R. 2009. Composting of animal manures and chemical criteria for compost maturity assessment: a review. Bioresource Technology 100: 5444-5453.). Next, TS content increased from the beginning of the process (207 and 275 g kg−1 in pile 1 and 2, respectively) to compost after maturation (498 and 682 g kg−1 in pile 1 and 2, respectively), indicating drying out of the material. But the organic matter (expressed as VS content) decreased in both systems from 762 ± 5 to 570 ± 37 g kg−1 dry weight (average ± sd), showing degradation due to microbial activity. Both, the drying out and the organic matter degradation led to a reduction in the total mass of the piles (on average 45 ± 4 % of dry matter in both systems; 77 ± 1 % of fresh weight). However, the concentration of TN and the other nutrients increased during the process as a concentration effect due to a reduction in the weight of the pile during OM degradation. However, the recovery of TN accounted for 58 and 77 %, in systems 1 and 2, respectively, indicating that the losses were higher in system 1 (42 %) than in 2 (23 %). The recovery of inorganic N (NH4+-N and NO3--N) in the mature compost accounted for 34 % in system 1 and 46 % in 2, further indicating conservation of nutrients with the use of cotton gin waste as bulking agent.

One of the main concerns related to pig slurry composting is the concentration of Cu and Zn, which can be particularly high in pig slurry from piglets (Moral et al., 2008Moral, R.; Pérez-Murcia, M.D.; Pérez-Espinosa, A.; Moreno-Caselles, J.; Paredes, C.; Rufete, B. 2008. Salinity, organic content, micronutrients and heavy metals in pig slurries from South-eastern Spain. Waste Management 28: 367–371.). These are mainly recovered from the pig slurry in the solid fraction, and later, after composting, in the compost produced. Then, 100 % of the Cu and Zn from the solid fraction of pig slurry were recovered in the mature compost, reaching very high concentrations in the mature composts which could limit the agricultural use of the compost. This was due to a concentration effect caused by the degradation of the organic matter during composting and previously during the high recovery in the solid fraction of the pig slurry. The composting process was very effective for hygienisation of the pig slurry, as the mature compost of both systems showed no detectable Salmonella (in 25 g compost), with E. coli <1 CFU mL−1 (Table 2).

Greenhouse gas emissions during composting are associated with CH4 and N2O. According to the IPCC under the farm conditions of this scenario, estimated CH4 emissions were 0.127 t CO2 eq m3 of manure, while CH4 emissions in the composting piles were about 0.0124 t CO2 eq m3 of manure, thus a reduction of 90 % was achieved (Figure 9).

Case 5: Collective treatment plant based on energy production in Tjele (Denmark)

The biogas plant was located at AU Foulum campus in Tjele (Denmark) and had been in operation since 2007. This location was chosen because of its manure storage area with three large lagoons.

The plant was unusual in several ways, due to the fact that it was used partly for research, and these differences are highlighted. The plant consisted of a thermophilic reactor 1,200 m3 in total volume with 1,100 m3 of working volume, constructed from steel with 200 mm glass wool insulation and a steel outer shell (Figure 5). In addition, two post digesters, 2,500 m3 each in volume were provided. These were constructed from a low precast concrete wall and a flexible top cover. The HRT in the main reactor was around 13-14 days, but it was considerably greater when the post digesters were included. The post digesters also served as gas storage for the main reactor, although storage time was less than two hours if the gas was not being used. The plant treats annually around 23,000 tons of liquid cattle and pig manure and 5,500 tons of deep litter, straw, grass and vegetable wastes of high dry matter content, producing 1,460,000 m3 of biogas at ca. 50 % CH4. The gas produced was cleaned to remove the greater part of the hydrogen sulphide and water vapor, and sent to the central heating plant at the main campus where it was burned in a 650 kWel CHP unit.

− Diagram of a collective treatment plant based on energy production in Tjele, (Denmark) (Case 5). Flow (Q), total solids (TS), volatile solids (VS), chemical oxygen demand (COD), total Kjeldahl nitrogen (TKN), ammonium (NH4+-N), total phosphorus (TP).

The treatment plant performance is shown in Table 1. The reduction of CO2 eq of the treatment plant scenario compared to baseline scenario is shown in Figure 9.

Case 6: Collective treatment and management based on energy production and nitrogen removal in Lombardy (Italy)

The management system studied was a collective treatment plant with an anaerobic digestion phase for energy production and a nitrogen removal phase. It was located in northern Italy, in the province of Bergamo, in an intensive livestock area where there is a high surplus of nitrogen and had been designated as a nitrate vulnerable zone (NVZ). The plant was managed by a society to which farmers were affiliated. They were involved in the project as they wanted to show the benefits they had garnered to the local administration and citizens.

The treatment plant involved 12 livestock units belonging to 10 farms (pigs, cows and poultry), located 0.5 to 6 km away from the plant, for a total daily production of around 235 m3 d−1 of manure. The manure was transported by slurry tanker, with the exception of the nearby farm, connected by means of a pipeline. At first, manure was processed in an anaerobic digestion reactor for the production of energy (Figure 6). This step consisted of two digesters, with a volume of 2,280 m3, and a post-digester (3,185 m3). One of the two digesters was fed with manure and other biomasses (silage) around 10 t per day, while the second one was fed with raw manure only. The digestate was then conveyed to the post digester. The digested effluent was then separated, in order to reduce the organic load and to separate most of the phosphorus. The solid-liquid separation treatment was performed by two screw press separators. The solid fraction was sold, while the liquid fraction was treated for biological nitrogen removal. This process was carried out by two SBRs, having a capacity of 660 m3 each, which operate in parallel. The cycles consisted of four steps: feed (15-20 m3 in 20 min), mixing (90 min), aeration (230 min) and settling (20 min). The effluent was ultimately stored in three storage tanks. Then, it was transported to farms by slurry tanker or pipeline.

− Diagram of a collective treatment and management plant based on energy production and nitrogen removal in Lombardy, (Italy) (Case 6). Flow (Q), total solids (TS), volatile solids (VS), chemical oxygen demand (COD), total Kjeldahl nitrogen (TKN), ammonium (NH4+-N), total phosphorus (TP).

The performance of the treatment in removing nitrogen (Table 1) was in line with expectation and the need to maintain a part of the fertilizing value of the slurry to meet crop demand. The reduction in pathogens was not relevant and in some cases some bacterial growth was recorded probably due to the favorable condition in the SBRs (Table 2). With regard to Cu and Zn content, the only removal effect was due to phase separation that slightly reduced the concentration of these heavy metals in the liquid fraction.

The GHG emissions were greatly influenced by the collective treatment system (Figure 9). Methane emission is a lot lower in the treatment plant scenario due to the recovery at the biogas plant. Of course, methane emission in the intermediate storage before transportation to the treatment plant entails some methane emission (collection was made weekly in each farm) and the end product still had some methane production potential since VS content was 1 % of the total mass of slurry applied to the land. However, the main methane emissions in the treatment plant scenario were related to methane losses due to leakages. The value used for this purpose (5 % of the methane produced) might be an overestimate, but there was limited information about losses from the biogas plants and further investigations are needed to obtain a more accurate assessment. The additional benefit of the treatment plant referred to the reduction of CO2 emissions due to the production of energy. The overall benefit in terms of total CO2 eq. reduction was 61 % which seems a very worthy achievement.

The reduction in GHGs obtained demonstrates how these collective management systems might be sustainable despite the higher emissions due to transportation. This operation should be carefully considered as it can contribute significantly to the reduction in emissions. In the case study considered, the CO2 emissions in the treatment plant scenario were almost twice that in the scenario without the plant as most of the slurry was transported in slurry tankers.

Case 7: Centralized treatment and management based on energy production and agronomic valorization in Navarra (Spain)

The system monitored was a centralized treatment plant consisting of an AD process for energy production. The plant was located in Navarra (Spain) and involved 3,000 livestock units of one dairy farm, poultry manure and other organic wastes coming mainly from the agro-food industry of the surrounding area, for a daily treatment capacity of approximately 600 m3 d−1. These co-substrates were transported to the treatment plant using road transport, while the dairy manure was transported through a 2 km long pipeline by gravity.

The substrates were homogenized in two covered tanks in line (Figure 7), shredded in a grinder pump to be fed to the process. In a second phase, the feed was treated in a pasteurization unit at 70 ºC for 1 hour. The temperature was raised with two heat exchangers that used the temperature of the flow at the exit of the digestion unit and the heat produced in the CHP units. After pasteurization, two process lines working in parallel treated the sanitized feed in a two-step anaerobic digestion process (digester followed by a post-digester) at an average temperature of 41 ºC for approximately 63 days. The solid-liquid separation of the digestate was carried out in a decanter-centrifuge: the solid fraction, with high phosphorus content, and the liquid fraction with high nitrogen content were stored in a closed warehouse and a covered storage tank respectively before land application near the treatment plant. Around 6,000 ha of crop fields were included in the nutrient management plan of the centralized treatment plant. The biogas produced was used by two CHP units (2 MW each). Average electric production was 92.8 kWh m−3 fed with average biogas production of 28,200 m3 d−1 (CH4 content of 60 %).

− Diagram of a centralized treatment and management plant based on energy production and agronomic valorization in Navarra, (Spain) (Case 7). Data correspond to average values; standard deviation is included. Flow (Q), total solids (TS), volatile solids (VS), chemical oxygen demand (COD), total Kjeldahl nitrogen (TKN), ammonium (NH4+-N), total phosphorus (TP).

The removal efficiency of the whole treatment system is shown in Table 1. The reduction of CO2 eq. of the treatment plant scenario compared to baseline scenario is shown in Figure 9.

Case 8: Centralized treatment and management based on energy production and agronomic valorization of pig manure in Castilla y León (Spain)

The system monitored was an AD centralized treatment plant for energy production. The plant was located in Soria (Spain) and involved 46 pig farms in the surrounding area. The pig manure was collected and transported to the treatment plant using road transport. A centralized transportation system was established with trucks having a capacity of 35 m3. The facility had a treatment capacity of 42,000 m3 yr−1.

The raw manure was transported to a reception and mixing unit where it was homogenized prior to feeding into the AD unit, as shown in Figure 8. The raw manure was preheated in a heat exchanger using the heat produced in the CHP unit before entering the digester. The anaerobic digestion step consisted of one digestion tank followed by a post-digestion tank, working at an average temperature of 38 ºC. The residence time was approximately 36 days. A vertical stirrer homogenized the digestate inside the tank. After the digestion, no presence of Salmonella was ever found and E. coli levels remained under 1000 CFU g−1.

− Diagram of a centralized treatment and management plant based on energy production and agronomic valorization of pig manure in Castilla y León, (Spain) (Case 8). Data correspond to average values; standard deviation is included. Flow (Q), total solids (TS), volatile solids (VS), chemical oxygen demand (COD), total Kjeldahl nitrogen (TKN), ammonium (NH4+-N), total phosphorus (TP).

The biogas produced was 1,500 m3 d−1 (CH4 content of 65 %). It was stored in an external gasometer and then fed to a CHP unit with electric power of 250 kWe for an average electric production of 70.3 kWh m−3. The digestate was stored in a tank for land spreading and used as a valuable organic fertilizer on the surrounding area.

In the process line of this treatment plant, there was no unit targeted at reducing the solid or the metal content of the digestate. Nevertheless, at the end of the process a reduction of approximately 16 and 14 % in the copper and zinc fed to the treatment, respectively, was observed.

The treatment plant performance is shown in Table 1. The reduction of CO2 eq. of the treatment plant scenario compared to baseline scenario is shown in Figure 9.

Discussion

Among the alternatives for improving manure management, biological processes are considered a solution (or part of the solution) due to their involvement in carbon, nitrogen and phosphorous cycles (Bernet and Béline, 2009Bernet, N.; Béline, F. 2009. Challenges and innovations on biological treatment of livestock effluents. Bioresource Technology 100: 5431-5436.). These alternatives include AD, which is one of the most widely used technologies due to its ability to generate renewable energy in the form of methane whilst reducing greenhouse gas emissions; however, N and P concentrations in the treated effluent are not reduced. To solve this problem, developing a well-established network for distributing the digestate is essential to successful application (Flotats et al., 2009). After AD there is the possibility of applying other unitary processes to remove N from the digestate, as described in Case 3 and 6 where the SHARON-SBR and NDN processes were applied, respectively, to the liquid fraction of the digestate after solid-liquid separation (Figures 3 and 6 6 IRTA UPC Caldes de Montbui Barcelona Spain IRTA – GIRO Joint Research Unit IRTA-UPC, Torre Marimon – E-08140 – Caldes de Montbui – Barcelona – Spain. ) in order to convert ammonium into nitrogen gas using these technological methods. Other processes like composting involve the mineralization and partial humification of the organic matter, leading to a stabilized final product, free of phytotoxicity and pathogens and with certain humic properties (Zucconi and Bertoldi, 1987Zucconi, F.; Bertoldi, M. 1987. Compost specifications for the production and characterization of compost from municipal solid waste. p. 30-50. In: Bertoldi, M.; Ferranti, M.P.; L´Hermite, P.; Zucconi, F., eds. Compost: production, quality and use. Elsevier Applied Science, Barking, UK.) that can be used to improve and maintain soil quality and fertility. Composting can be applied to raw manure after solid-liquid separation, as in Case 4. However, it can also be applied to digestate (after solid-liquid separation too), as in Case 2. Aerobic processes, as described in Case 1, also represented a good treatment alternative, allowing for the reduction of N and thus, being a good option in NVZ where there is an N surplus. In this particular case, the application of a pre-treatment of raw manure involving the separation of the solid fraction from the liquid fraction, prior NDN technology has been reported to make the treatment of the liquid fraction more economical and feasible (Riaño and García-González, 2014Riaño, B.; García-González, M.C. 2014. On-farm treatment of swine manure based on solid-liquid separation and biological nitrification-denitrification of the liquid fraction. Journal of Environmental Management 132: 87-93.). These examples showed that there are multiple technological alternatives for improving manure management; the question is to find the most suitable for each particular case and local circumstances, as well as its environmental and economical feasibility, because there is no universal solution.

Each of the manure treatment plants monitored had been designed to meet the particular needs of the farm which includes the following: land disposal, soil characteristics, agricultural practices, social surroundings, development of sustainable manure management. In the case of AD, plant digestate was used as crop fertilizers near the plants, as in Cases 5, 7 and 8; similarly to Cases 3 and 6 but in these cases nutrient reduction was needed, i.e. in Case 3 the solids and the liquid fraction were applied to maize and wheat crops near the farm after a reduction in nutrients, due to their being located in NVZ. On the contrary, Cases 2 and 4 recovered nutrients to export them from the farm and obtain valuable compost. Similarly, Case 1 strategy was to export nutrients through solid-liquid separation and the NDN of the liquid fraction as this farm had no available land where manure could be applied and was located in an N surplus area.

Performance of the plants

In the case of the AD plants monitored (Cases 5, 7, and 8) it is necessary to underline that the AD process does not remove N, P and heavy metals, as these elements are distributed among the solid and the liquid fractions, but the process was able to remove COD and TS. Reported Cu and Zn reduction values in Case 7 and 8 were due to precipitation in the storage tank. Specifically, overall removal percentages ranged between 35 and 53 % for COD and 24 and 61 % for TS (Table 1), Case 7 being the most efficient. Anaerobic digestion plants combined with nitrogen removal processes (Case 3 and 6) had excellent removal performances recording values of 93 % and 77 % for COD removal and 70 % and 66% for TS removal respectively (Table 1). Similar results were obtained by Kunz et al. (2009)Kunz, A.; Miele, M.; Steinmetz, R.L.R. 2009. Advanced swine manure treatment and utilization in Brazil. Bioresource Technology 100: 5485-5489. when treating swine manure in a combined AD + aerobic reactor, with removal values of 93 % of COD and 99 % of settled solids. Most of the nutrients were removed from both systems, it being possible to maintain the fertilizing value of the slurry for crop demand after the treatment, as indicated in Case 6. Therefore, nutrient removal systems in combination with AD allowed for energy recovery as well as a reduction in nutrients to a level appropriate for use in the soil. In Case 2, the recovery of nutrients from digestate was carried out in order to compost the solids for exporting these nutrients from the farm. Thus, considering the whole process 54 % of carbon (in the form of COD) and 10 % of P were recovered (Figure 2). However, N recovery was very poor, only 4 %, meaning that most N in digestate was NH4+ and was not recovered in the solid fraction. In this case study to calculate the performance of the treatment plant (Table 1) the whole process that included AD and composting of the solid fraction was considered, being sampling points initial raw manure being used as sampling points of departure, solid fraction and liquid fraction after solid-liquid separation. However, in Figure 2 data from the final effluent was sampled from the storage tank, where the liquid fraction of the digestate was stored for between 4-6 months. During this period degradation of the organic matter, volatilization of NH4+ as well as solid precipitation occurred. For this reason values reported in Table 1 and Figure 2 are not coincident.

In Case 4, where the solid fractions of manure were composted, the major concern was to control C and N-losses since they reduce the agronomic value of compost and contribute to greenhouse gas emissions (Hao et al., 2004Hao, X.; Chang, C.; Larney, F.J. 2004. Carbon, nitrogen balances and greenhouse gas emissions during cattle feedlot manure composting. Journal of Environmental Quality 33: 37-44.). During the composting of animal manures organic-C and N-losses in pig manure can reach 72 and 60 % (Bernal et al, 2009Bernal, M.P.; Alburquerque, J.A.; Moral, R. 2009. Composting of animal manures and chemical criteria for compost maturity assessment: a review. Bioresource Technology 100: 5444-5453.). In the plant monitored, these losses were below these percentages, with values of 59 and 33 % (Table 1), which means that more nutrients will be available for crops. Regarding Cu and Zn, the composting process do not remove these elements, they concentrate as moisture content decreases; thus, it is important to reduce heavy metals in manure in order to meet legislation requirements for the application of compost to soil. In Case 1, removals of organic matter and nutrients were very high (Table 1), similar to those obtained by Vanotti et al. (2007)Vanotti, M.B.; Szogi, A.A.; Hunt, P.G.; Millner, P.D.; Humenik, F.J. 2007. Development of environmentally superior treatment system to replace anaerobic swine waste lagoons in the USA. Bioresource Technology 98: 3184-3194. with removals of up to 95 %, which were very convenient for the farm as it needed to export these nutrients (solid fraction) and remove the excess of N in the liquid fraction. However, this system does not recover energy like those based on AD.

Pathogen reduction

Animal manure and slurries may contain a variety of pathogenic microorganisms, i.e. bacteria such as the Salmonella species, Campylobacter jejuni, and E. coli 0157:H7, parasites such as Cryptosporidium parvum, and viruses such as enteroviruses (Sobsey et al., 2001Sobsey, M.D.; Khatib, L.A.; Hill, V.R.; Alocilja, E.; Pillai, S. 2001. Pathogens in Animal Wastes and the Impacts of Waste Management Practices on Their Survival, Transport and Fate. In: White Papers on Animal Agriculture and the Environment. MidWest Plan Service (MWPS)/Iowa State University, Ames, IA, USA (Chapter 17).). Thus, one of the major interests in monitoring the manure treatment plants was to study the rates of pathogen reduction, considering E. coli and Salmonella as indicators. In the case of AD plants (Case 5, 7, 8), Case 7 was the most efficient in removing both Salmonella and E. coli with reductions of 3.6 log10. All AD plants were able to destroy Salmonella (Table 2), and reduce E. coli below 3 log10, which reduces the risk of pathogens contaminating the environment while recycling digestate to agricultural land.

In the case of AD and nutrient removal (Case 3, 6), there are no data from Case 3, and in Case 6 AD was able to reduce E. coli 1.5 log10, but a cross-contamination of Salmonella occurred somewhere in the treatment process. Anaerobic digestion followed by composting (Case 2) was very efficient in removing pathogens, as E. coli was reduced by 2.5 log10 and Salmonella was not detected. As regards composting alone (Case 4), it was also very efficient recording reductions of 5 log10 for E. coli (Table 2) avoiding the risk of spreading pathogens associated with direct land application of manure. Finally, in Case 1, the NDN plant destroyed Salmonella and reduced E. coli by 2.2 log10, although the treatment was less efficient in reducing this pathogen (Table 2). Similar results were obtained by Vanotti et al. (2009)Vanotti, M.B.; Szogi, A.A.; Millner, P.D.; Loughrin, J.H. 2009. Development of a second-generation environmentally superior technology for treatment of swine manure in the USA. Bioresource Technology 100: 5406-5416., recording a pathogen reduction of 2.6 log10 in the biological N treatment.

In slurry subjected to AD, pathogenic microorganisms are eliminated more effectively in comparison with aerated slurry; however, although mesofilic AD of manure alone or co-digestion with other substrates does not lead to a reliable inactivation of pathogens, since the exposure time during the standard operation is too short (Martens and Böhm, 2009Martens, W.; Böhm, R. 2009. Overview of the ability of different treatment methods for liquid and solid manure to inactivate pathogens. Bioresource Technology 100: 5374-5378.), this technology contributes to the inactivation of pathogens. However, in order to have safe end products, the treatment must be combined with a pre-pasteurisation step or followed by composting of the separated solid fraction (EFSA, 2007European Food Safety Authority [EFSA]. 2007. Opinion on the Scientific Panel on Biological Hazards on the safety vis-à-vis biological risk of the mesophilic process of biogas and compost treatment of animal by-products (ABPs) (Question Nº EFSA-Q-2006-126). Adopted on 8 March 2007. The EFSA Journal 465: 1-16.), as in Case 2.

GHG reduction

The most important GHG emissions during manure storage, treatment, and land spreading were: (1) methane (CH4) emissions produced during manure digestion under anaerobic conditions, and (2) nitrous oxide (N2O) emissions during storage and manure handling. All treatment plants reported high GHG emission reductions when the baseline scenario was compared with the treatment plant scenario. In general, GHG emissions were reduced by at least 53 % (Case 8, Figure 9), although some treatment plants achieved reductions above 75 % (Case 5 and 7) and 90 % for the composting process (Case 4). Differences in GHG emissions between AD scenarios were basically due to VS and TKN content in raw manure, as their presence in the content of raw manure is high and most GHG emissions will be produced under the scenario monitored, as well as the differences in transportation distances from farms to the treatment plants. Another fact to consider is that as previously mentioned, AD did not reduce N; thus, the digestate will need further post-treatment, like in Case 3 and 6, or land application planning that is well-established. In this case, emissions derived from the transport and land application of digestate will be the same as from raw manure. The advantages of AD were due to the reduction in CH4 emissions during storage of the raw manure and the utilization of these CH4 emissions for energy production which avoids the consumption of fossil fuels.

Conclusions

In this study, eight different case studies featuring on-farm and collective manure treatment plants were evaluated. The implementation of all treatment plants studied supposed significant reductions in GHG emissions in comparison to the baseline scenario, with estimated values ranging between 53 (Case 8) and 90 % (Case 4). Organic matter and TS content in manure were also greatly reduced, as well as N concentrations in those plants with N-removal units (Case 1, 3 and 6). As regards pathogens, they were removed or greatly reduced in most of the plants monitored.

The study demonstrated that there are multiple technologies with different complexity levels suitable for the treatment of manure in terms of removal and management of organic matter and nutrients. Although there is no universal solution for manure management, the treatments represent a workable strategy in a number of areas, especially in NVZ and nutrient surplus areas. The application of one or other technologies will depend on the farm size, local geography, land type, and climate and production systems that give rise to farms with highly individual features.

Acknowledgements

This study was funded by the European Union under the Project Life MANEV (LIFE9-ENV-ES-0453) “Evaluation of manure management and treatment technologies for environmental protection and sustainable livestock farming in Europe”.

References

- American Public Health Association [APHA]. 2005. Standard Methods for the Examination of Water and Wastewater. 21ed. American Public Health Association, Washington, DC, USA.

- Bernal, M.P.; Alburquerque, J.A.; Moral, R. 2009. Composting of animal manures and chemical criteria for compost maturity assessment: a review. Bioresource Technology 100: 5444-5453.

- Bernet, N.; Béline, F. 2009. Challenges and innovations on biological treatment of livestock effluents. Bioresource Technology 100: 5431-5436.

- Cerutti, A.K.; Bagliani, M.; Beccaro, G.L.; Giolli, F.; Balsari, P.; Bounous, G. 2011. Evaluation of the sustainability of swine manure fertilization in orchard through ecological footprint analysis: results from a case study in Italy. Journal of Cleaner Production 19: 318-324.

- European Food Safety Authority [EFSA]. 2007. Opinion on the Scientific Panel on Biological Hazards on the safety vis-à-vis biological risk of the mesophilic process of biogas and compost treatment of animal by-products (ABPs) (Question Nº EFSA-Q-2006-126). Adopted on 8 March 2007. The EFSA Journal 465: 1-16.

- Hao, X.; Chang, C.; Larney, F.J. 2004. Carbon, nitrogen balances and greenhouse gas emissions during cattle feedlot manure composting. Journal of Environmental Quality 33: 37-44.

- Intergovernmental Panel on Climate Change [IPCC]. 2006. IPCC guidelines for national greenhouse gas inventories. Available at: http://www.ipcc-nggip.iges.or.jp/public/2006gl/index.html [Accessed Jun. 13, 2013]

» http://www.ipcc-nggip.iges.or.jp/public/2006gl/index.html - Kunz, A.; Miele, M.; Steinmetz, R.L.R. 2009. Advanced swine manure treatment and utilization in Brazil. Bioresource Technology 100: 5485-5489.

- López-Ridaura, S.; Werf, H. van der; Paillat, J.M.; Le Bris, B. 2009. Environmental evaluation of transfer and treatment of excess pig slurry by life cycle assessment. Journal of Environmental Management 90: 1296-1304.

- Martens, W.; Böhm, R. 2009. Overview of the ability of different treatment methods for liquid and solid manure to inactivate pathogens. Bioresource Technology 100: 5374-5378.

- Moral, R.; Pérez-Murcia, M.D.; Pérez-Espinosa, A.; Moreno-Caselles, J.; Paredes, C.; Rufete, B. 2008. Salinity, organic content, micronutrients and heavy metals in pig slurries from South-eastern Spain. Waste Management 28: 367–371.

- Oficina Catalana del Cambio Climático [OCCC]. 2013. Methodology for the estimation of the electrical mix for the Catalan Office for Climate Change. Available at: http://canviclimatic.gencat.cat/web/.content/home/redueix_emissions/factors_emissio_associats_energia/150213_Nota-metodologica-mix_cast.pdf [Accessed Jan. 8, 2016]

» http://canviclimatic.gencat.cat/web/.content/home/redueix_emissions/factors_emissio_associats_energia/150213_Nota-metodologica-mix_cast.pdf - Petersen, S.O.; Sommer, S.; Béline, F.; Burton, C.; Dach, J.; Dourmad, J.; Leip, A.; Misselbrook, T.; Nicholson, F.; Poulsen, H.D.; Provolo, G..; Sørensen, P.; Vinneras, B.; Weiske, A.; Bernal, M.P.; Böhm, R.; Juhász, C.; Mihelic, R. 2007. Recycling of livestock manure in a whole-farm perspective. Livestock Science 112: 180-191.

- Riaño, B.; García-González, M.C. 2014. On-farm treatment of swine manure based on solid-liquid separation and biological nitrification-denitrification of the liquid fraction. Journal of Environmental Management 132: 87-93.

- Sobsey, M.D.; Khatib, L.A.; Hill, V.R.; Alocilja, E.; Pillai, S. 2001. Pathogens in Animal Wastes and the Impacts of Waste Management Practices on Their Survival, Transport and Fate. In: White Papers on Animal Agriculture and the Environment. MidWest Plan Service (MWPS)/Iowa State University, Ames, IA, USA (Chapter 17).

- Teira-Esmatges, M.R.; Flotats, X. 2003. A method for livestock waste management planning in NE Spain. Waste Management 23: 917-932.

- Vanotti, M.B.; Szogi, A.A.; Hunt, P.G.; Millner, P.D.; Humenik, F.J. 2007. Development of environmentally superior treatment system to replace anaerobic swine waste lagoons in the USA. Bioresource Technology 98: 3184-3194.

- Vanotti, M.B.; Szogi, A.A.; Millner, P.D.; Loughrin, J.H. 2009. Development of a second-generation environmentally superior technology for treatment of swine manure in the USA. Bioresource Technology 100: 5406-5416.

- Zucconi, F.; Bertoldi, M. 1987. Compost specifications for the production and characterization of compost from municipal solid waste. p. 30-50. In: Bertoldi, M.; Ferranti, M.P.; L´Hermite, P.; Zucconi, F., eds. Compost: production, quality and use. Elsevier Applied Science, Barking, UK.

Edited by

Publication Dates

-

Publication in this collection

Sep-Oct 2016

History

-

Received

10 Feb 2015 -

Accepted

23 Oct 2015