Abstract

Biodegradable polymers (e.g. poly(butylene succinate) - PBS) have been used in several sectors such as the environmental area, especially in bioremediation, in biological processes for conversion of pollutants into inorganic compounds. In this study, the foresight methodology for the use of biodegradable polymers, including PBS, reveals a publication rate of approximately 8.74 articles and 30.63 patents per year, between 2005 and 2019. However, the application of PBS, specifically, is still restricted to the environmental area, with only 3.0% of the 1484 works from this period. The results showed a more significant number of papers on the PBS application for synthesis, characterization, and application in the areas of Chemistry, Physics, and Pharmacy. In the area of bioremediation, only three studies related to PBS were found, revealing the lack of research and development to increase the contribution in the area of environmental recovery.

Keywords:

biodegradable polymer; biopolymer; bioremediation; foresight methodology; poly(butylene succinate)

1. Introduction

From Antiquity to the present days, the demand for oil and its derivatives has been growing largely due to the population increase, the urbanization of large centers, and the value of oil in the international market. The high consumption of these inputs implies their higher exploration and processing, which may result in damage to the environment due to its well drilling and extraction activities, refining and transportation to commercialization, and final disposal. Pollution may occur in the land, air, or water environments, although land and sea fuel leaks are best known to the population[11 Patin, S. (2013). Environmental impact of crude oil spills. In S. Patin. Reference module in earth systems and environmental sciences. Cambridge: Elsevier. http://dx.doi.org/10.1016/B978-0-12-409548-9.01221-5

http://dx.doi.org/10.1016/B978-0-12-4095...

,22 Souza, E. C., Vessoni-Penna, T. C., & de Souza Oliveira, R. P. (2014). Biosurfactant-enhanced hydrocarbon bioremediation: an overview. International Biodeterioration & Biodegradation, 89, 88-94. http://dx.doi.org/10.1016/j.ibiod.2014.01.007.

http://dx.doi.org/10.1016/j.ibiod.2014.0...

]. As an alternative to polymers derived from fossil fuels, biopolymers and biodegradable polymers are widely used, having great importance in the biomedical and drug areas, since they are obtained from natural resources, are biodegradable and present a high affinity with biological systems[33 Witzler, M., Alzagameem, A., Bergs, M., Khaldi-Hansen, B. E., Klein, S. E., Hielscher, D., Kamm, B., Kreyenschmidt, J., Tobiasch, E., & Schulze, M. (2018). Lignin-derived biomaterials for drug release and tissue engineering. Molecules, 23(8), 1885. http://dx.doi.org/10.3390/molecules23081885. PMid:30060536.

http://dx.doi.org/10.3390/molecules23081...

,44 Mhlwatika, Z., & Aderibigbe, B. (2018). Polymeric nanocarriers for the delivery of antimalarials. Molecules (Basel, Switzerland), 23(10), 2527. http://dx.doi.org/10.3390/molecules23102527. PMid:30279405.

http://dx.doi.org/10.3390/molecules23102...

]. Its application in the environmental area is prevalent and has increased in the recent years. Therefore, the main objective of this work is to map the evolution of international studies and resulting publications in the environmental sector over a period of 15 years[55 Reis, E. A., Rocha-Leão, M. H. M., & Leite, S. G. F. (2013). Slow-release nutrient capsules for microorganism stimulation in oil remediation. Applied Biochemistry and Biotechnology, 169(4), 1241-1249. http://dx.doi.org/10.1007/s12010-012-0022-0. PMid:23306878.

http://dx.doi.org/10.1007/s12010-012-002...

6 Dzionek, A., Wojcieszyńska, D., & Guzik, U. (2016). Natural carriers in bioremediation: A review. Electronic Journal of Biotechnology, 23, 28-36. http://dx.doi.org/10.1016/j.ejbt.2016.07.003.

http://dx.doi.org/10.1016/j.ejbt.2016.07...

7 Chaisorn, W., Prasertsan, P., O-Thong, S., & Methacanon, P. (2016). Production and characterization of biopolymer as bioflocculant from thermotolerant Bacillus subtilis WD161 in palm oil mill effluent. International Journal of Hydrogen Energy, 41(46), 21657-21664. http://dx.doi.org/10.1016/j.ijhydene.2016.06.045.

http://dx.doi.org/10.1016/j.ijhydene.201...

-88 Caetano, R. M. J., Bedor, P. B. A., de Jesus, E. F. O., Leite, S. G. F., & Souza, F. G. Jr (2018). Oil biodegradation systems based on γ irradiated Poly (Butylene Succinate). Macromolecular Symposia, 380(1), 1800123. http://dx.doi.org/10.1002/masy.201800123.

http://dx.doi.org/10.1002/masy.201800123...

]. The mapping was done to addressing bioremediation, which has been a very prominent approach in the environmental area. This work was completed with a case study for PBS, a polymer that might be highlighted as promising for biostimulation exploration, one of the potential existing bioremediation techniques.

2. Biodegradable Polymers, Biopolymers, and Green Polymers: Definitions and Applications

According to the IUPAC[99 Nič, M., Jirát, J., Košata, B., Jenkins, A., & McNaught, A. (2009). Compendium of chemical terminology: Gold Book (2.1.0.). Research Triagle Park, NC: IUPAC. https://doi.org/10.1351/goldbook

https://doi.org/10.1351/goldbook...

], biodegradable polymers are defined as susceptible to degradation by biological activity followed by a decrease in their molar mass.

Biodegradable polymers are divided in bio-based or petrochemical-based polymers based on their origin[1010 Doppalapudi, S., Jain, A., Khan, W., & Domb, A. J. (2014). Biodegradable polymers-an overview: BIODEGRADABLE POLYMERS. Polymers for Advanced Technologies, 25(5), 427-435. http://dx.doi.org/10.1002/pat.3305.

http://dx.doi.org/10.1002/pat.3305...

]. Bio-based polymers are called biopolymers or “green polymers” since they are derived from renewable sources such as animals, plants, algae, and bacteria[1111 Hernández, N., Williams, R. C., & Cochran, E. W. (2014). The battle for the “green” polymer. Different approaches for biopolymer synthesis: Bioadvantaged vs. bioreplacement. Organic & Biomolecular Chemistry, 12(18), 2834-2849. http://dx.doi.org/10.1039/C3OB42339E. PMid:24687118.

http://dx.doi.org/10.1039/C3OB42339E...

12 Vinod, A., Sanjay, M. R., Suchart, S., & Jyotishkumar, P. (2020). Renewable and sustainable biobased materials: an assessment on biofibers, biofilms, biopolymers and biocomposites. Journal of Cleaner Production, 258, 120978. http://dx.doi.org/10.1016/j.jclepro.2020.120978.

http://dx.doi.org/10.1016/j.jclepro.2020...

-1313 Modi, V. K., Shrives, Y., Sharma, C., Sen, P. K., & Bohidar, S. K. (2007). Review on green polymer nanocomposite and their applications. International Journal of Innovative Research in Science, Engineering and Technology, 3, 17651-17656.]. Biopolymers may to be obtained in different forms: (i) available in the natural environment in the form of polysaccharides (e.g. cellulose, alginate, chitin)[99 Nič, M., Jirát, J., Košata, B., Jenkins, A., & McNaught, A. (2009). Compendium of chemical terminology: Gold Book (2.1.0.). Research Triagle Park, NC: IUPAC. https://doi.org/10.1351/goldbook

https://doi.org/10.1351/goldbook...

,1414 Anderson, L. A., Islam, M. A., & Prather, K. L. J. (2018). Synthetic biology strategies for improving microbial synthesis of “green” biopolymers. The Journal of Biological Chemistry, 293(14), 5053-5061. http://dx.doi.org/10.1074/jbc.TM117.000368. PMid:29339554.

http://dx.doi.org/10.1074/jbc.TM117.0003...

], exopolysaccharides, and proteins (e.g. biofilms)[1515 Velichko, N. S., Grinev, V. S., & Fedonenko, Y. P. (2020). Characterization of biopolymers produced by planktonic and biofilm cells of Herbaspirillum lusitanum P6-12. Journal of Applied Microbiology, jam.14647. http://dx.doi.org/10.1111/jam.14647. PMid:32216024.

http://dx.doi.org/10.1111/jam.14647...

]; (ii) from microbial production or fermentation (e.g., PHB, PBS)[1616 Xu, Y., Xu, J., Liu, D., Guo, B., & Xie, X. (2008). Synthesis and characterization of biodegradable poly(butylene succinate-co-propylene succinate)s. Journal of Applied Polymer Science, 109(3), 1881-1889. http://dx.doi.org/10.1002/app.24544.

http://dx.doi.org/10.1002/app.24544...

,1717 Rajan, K. P., Thomas, S. P., Gopanna, A., & Chavali, M. (2019). Polyhydroxybutyrate (PHB): A standout biopolymer for environmental sustainability. In L. M. T. Martínez, O. V. Kharissova, & B. I. Kharisov (Eds.), Handbook of ecomaterials (pp. 2803-2825). Cham: Springer International Publishing. http://dx.doi.org/10.1007/978-3-319-68255-6_92

http://dx.doi.org/10.1007/978-3-319-6825...

], or (iii) chemically synthesized from biomass (e.g.PLA)[1818 Jaiswal, L., Shankar, S., & Rhim, J.-W. (2019). Applications of nanotechnology in food microbiology. In V. Gurtler, A. S. Ball, S. Soni. Methods in microbiology (Vol. 46, pp. 43-60). Cambridge: Elsevier. https://doi.org/10.1016/bs.mim.2019.03.002

https://doi.org/10.1016/bs.mim.2019.03.0...

].

Biopolymers have several advantages over petrochemical-based polymers, since they are obtained from renewable natural sources[1919 Islam, M., & Martinez-Duarte, R. (2017). A sustainable approach for tungsten carbide synthesis using renewable biopolymers. Ceramics International, 43(13), 10546-10553. http://dx.doi.org/10.1016/j.ceramint.2017.05.118.

http://dx.doi.org/10.1016/j.ceramint.201...

], have a low-cost extraction, and present characteristics of biocompatibility[2020 Vetrik, M., Mattova, J., Mackova, H., Kucka, J., Pouckova, P., Kukackova, O., Brus, J., Eigner-Henke, S., Sedlacek, O., Sefc, L., Stepanek, P., & Hruby, M. (2018). Biopolymer strategy for the treatment of Wilson’s disease. Journal of Controlled Release, 273, 131-138. http://dx.doi.org/10.1016/j.jconrel.2018.01.026. PMid:29407674.

http://dx.doi.org/10.1016/j.jconrel.2018...

] and biodegradability[2121 Ceccacci, A. C., Chen, C.-H., Hwu, E.-T., Morelli, L., Bose, S., Bosco, F. G., & Boisen, A. (2017). Blu-Ray-based micromechanical characterization platform for biopolymer degradation assessment. Sensors and Actuators. B, Chemical, 241, 1303-1309. http://dx.doi.org/10.1016/j.snb.2016.09.190.

http://dx.doi.org/10.1016/j.snb.2016.09....

]. Thus, biopolymers have been traditionally used in industrial activities related to food[2222 Lopez-Rubio, A., Fabra, M. J., Martinez-Sanz, M., Mendoza, S., & Vuong, Q. V. (2017). Biopolymer-based coatings and packaging structures for improved food quality. Journal of Food Quality, 1-2, 1-2. http://dx.doi.org/10.1155/2017/2351832.

http://dx.doi.org/10.1155/2017/2351832...

23 Moschakis, T., & Biliaderis, C. G. (2017). Biopolymer-based coacervates: Structures, functionality and applications in food products. Current Opinion in Colloid & Interface Science, 28, 96-109. http://dx.doi.org/10.1016/j.cocis.2017.03.006.

http://dx.doi.org/10.1016/j.cocis.2017.0...

-2424 Jung, E. Y., Jin, S. K., & Hur, S. J. (2018). Analysis of the effects of biopolymer encapsulation and sodium replacement combination technology on the quality characteristics and inhibition of sodium absorption from sausage in mice. Food Chemistry, 250, 197-203. http://dx.doi.org/10.1016/j.foodchem.2018.01.065. PMid:29412911.

http://dx.doi.org/10.1016/j.foodchem.201...

], biomedical[2525 Park, S.-B., Lih, E., Park, K.-S., Joung, Y. K., & Han, D. K. (2017). Biopolymer-based functional composites for medical applications. Progress in Polymer Science, 68, 77-105. http://dx.doi.org/10.1016/j.progpolymsci.2016.12.003.

http://dx.doi.org/10.1016/j.progpolymsci...

], and pharmaceutical production[2626 Singh, B. G., Das, R. P., & Kunwar, A. (2019). Protein: a versatile biopolymer for the fabrication of smart materials for drug delivery. Journal of Chemical Sciences, 131(9), 91. http://dx.doi.org/10.1007/s12039-019-1671-0.

http://dx.doi.org/10.1007/s12039-019-167...

,2727 Sithole, M. N., Choonara, Y. E., du Toit, L. C., Kumar, P., Marimuthu, T., Kondiah, P. P. D., & Pillay, V. (2018). Development of a novel Polymeric Nanocomposite complex for drugs with low bioavailability. AAPS PharmSciTech, 19(1), 303-314. http://dx.doi.org/10.1208/s12249-017-0796-z. PMid:28717975.

http://dx.doi.org/10.1208/s12249-017-079...

], as well as applications in the environmental sector[2828 Agostini de Moraes, M., Cocenza, D. S., Cruz Vasconcellos, F., Fraceto, L. F., & Beppu, M. M. (2013). Chitosan and alginate biopolymer membranes for remediation of contaminated water with herbicides. Journal of Environmental Management, 131, 222-227. http://dx.doi.org/10.1016/j.jenvman.2013.09.028. PMid:24178315.

http://dx.doi.org/10.1016/j.jenvman.2013...

29 Song, W., Gao, B., Xu, X., Xing, L., Han, S., Duan, P., Song, W., & Jia, R. (2016). Adsorption-desorption behavior of magnetic amine/Fe3O4 functionalized biopolymer resin towards anionic dyes from wastewater. Bioresource Technology, 210, 123-130. http://dx.doi.org/10.1016/j.biortech.2016.01.078. PMid:26852273.

http://dx.doi.org/10.1016/j.biortech.201...

-3030 Narayanan, N., Gupta, S., Gajbhiye, V. T., & Manjaiah, K. M. (2017). Optimization of isotherm models for pesticide sorption on biopolymer-nanoclay composite by error analysis. Chemosphere, 173, 502-511. http://dx.doi.org/10.1016/j.chemosphere.2017.01.084. PMid:28131920.

http://dx.doi.org/10.1016/j.chemosphere....

].

3. Biopolymers in the Environmental Area

Most of the applications and environmental research present in the literature addresses bio-based biodegradable polymers. These polymers aim to improve processes such as emulsion stabilization[3131 El Asjadi, S., Nederpel, Q. A., Cotiuga, I. M., Picken, S. J., Besseling, N. A. M., Mendes, E., & Lommerts, B. J. (2018). Biopolymer scleroglucan as an emulsion stabilizer. Colloids and Surfaces. A, Physicochemical and Engineering Aspects, 546, 326-333. http://dx.doi.org/10.1016/j.colsurfa.2018.02.035.

http://dx.doi.org/10.1016/j.colsurfa.201...

], removal of contaminants from aqueous solutions[3232 Song, W., Gao, B., Wang, H., Xu, X., Xue, M., Zha, M., & Gong, B. (2017). The rapid adsorption-microbial reduction of perchlorate from aqueous solution by novel amine-crosslinked magnetic biopolymer resin. Bioresource Technology, 240, 68-76. http://dx.doi.org/10.1016/j.biortech.2017.03.064. PMid:28341379.

http://dx.doi.org/10.1016/j.biortech.201...

], composition of coating materials for protecting active agents from the environment[3333 Lopez-Pena, C. L., & McClements, D. J. (2015). Impact of a food-grade cationic biopolymer (ε-polylysine) on the digestion of emulsified lipids: in vitro study. Food Research International, 75, 34-40. http://dx.doi.org/10.1016/j.foodres.2015.05.025. PMid:28454965.

http://dx.doi.org/10.1016/j.foodres.2015...

,3434 La Mantia, F. P., Ceraulo, M., Mistretta, M. C., & Morreale, M. (2018). Rheological behaviour, mechanical properties and processability of biodegradable polymer systems for film blowing. Journal of Polymers and the Environment, 26(2), 749-755. http://dx.doi.org/10.1007/s10924-017-0995-4.

http://dx.doi.org/10.1007/s10924-017-099...

], and controlled release of active substances (e.g. drugs, fertilizers, and nutrients)[55 Reis, E. A., Rocha-Leão, M. H. M., & Leite, S. G. F. (2013). Slow-release nutrient capsules for microorganism stimulation in oil remediation. Applied Biochemistry and Biotechnology, 169(4), 1241-1249. http://dx.doi.org/10.1007/s12010-012-0022-0. PMid:23306878.

http://dx.doi.org/10.1007/s12010-012-002...

,3535 Hsu, S.-T., & Yao, Y. L. (2013). Effect of drug loading and laser surface melting on drug release profile from biodegradable polymer. Journal of Applied Polymer Science, 130(6), 4147-4156. https://doi.org/10.1002/app.39664

https://doi.org/10.1002/app.39664...

,3636 Tan, L., Jiang, T., Yang, X., Li, W., Pan, L., & Yu, M. (2015). Core-shell biopolymer microspheres for sustained drug release. Journal of Applied Polymer Science, 132(14). https://doi.org/10.1002/app.41782

https://doi.org/10.1002/app.41782...

].

The use of biopolymers is highlighted since most of the biopolymers obtained by fermentation are readily hydrolysable polyesters[3737 Rizzarelli, P., & Carroccio, S. (2014). Modern mass spectrometry in the characterization and degradation of biodegradable polymers. Analytica Chimica Acta, 808, 18-43. http://dx.doi.org/10.1016/j.aca.2013.11.001. PMid:24370091.

http://dx.doi.org/10.1016/j.aca.2013.11....

]. The hydrolysis of these biopolymers produces smaller molecules that are absorbed by microorganisms and are transformed into innocuous products such as water and carbon dioxide and converted into cellular biomass[3838 Ding, M., Zhang, M., Yang, J., & Qiu, J.-H. (2012). Study on the enzymatic degradation of aliphatic polyester-PBS and its copolymers. Journal of Applied Polymer Science, 124(4), 2902-2907. http://dx.doi.org/10.1002/app.35347.

http://dx.doi.org/10.1002/app.35347...

]. Studies have also been carried out about the ecotoxicological evaluation of the biodegradable polymers in the soil, as in the case of the polyesters poly(butyl adipate-co-terephtalate) (PBAT) and poly(lactic acid) (PLA)[2828 Agostini de Moraes, M., Cocenza, D. S., Cruz Vasconcellos, F., Fraceto, L. F., & Beppu, M. M. (2013). Chitosan and alginate biopolymer membranes for remediation of contaminated water with herbicides. Journal of Environmental Management, 131, 222-227. http://dx.doi.org/10.1016/j.jenvman.2013.09.028. PMid:24178315.

http://dx.doi.org/10.1016/j.jenvman.2013...

].

Studies in the literature have reported the use of biopolymers as essential factors in the processes of bioremediation, recovery of degraded environments, and remediation of heavy metals and petroleum derivatives through natural biopolymers, such as polypeptides and polysaccharides[2828 Agostini de Moraes, M., Cocenza, D. S., Cruz Vasconcellos, F., Fraceto, L. F., & Beppu, M. M. (2013). Chitosan and alginate biopolymer membranes for remediation of contaminated water with herbicides. Journal of Environmental Management, 131, 222-227. http://dx.doi.org/10.1016/j.jenvman.2013.09.028. PMid:24178315.

http://dx.doi.org/10.1016/j.jenvman.2013...

,3939 Song, W., Gao, B., Xu, X., Wang, F., Xue, N., Sun, S., Song, W., & Jia, R. (2016). Adsorption of nitrate from aqueous solution by magnetic amine-crosslinked biopolymer based corn stalk and its chemical regeneration property. Journal of Hazardous Materials, 304, 280-290. http://dx.doi.org/10.1016/j.jhazmat.2015.10.073. PMid:26561752.

http://dx.doi.org/10.1016/j.jhazmat.2015...

,4040 Wilton, N., Lyon-Marion, B. A., Kamath, R., McVey, K., Pennell, K. D., & Robbat, A. Jr (2018). Remediation of heavy hydrocarbon impacted soil using biopolymer and polystyrene foam beads. Journal of Hazardous Materials, 349, 153-159. http://dx.doi.org/10.1016/j.jhazmat.2018.01.041. PMid:29414747.

http://dx.doi.org/10.1016/j.jhazmat.2018...

]. Studies about the processes of bioremediation of environmental contaminants[4141 Tanida, I., Sakaue, A., & Osawa, S. (2014). Development of a safe solid-state microorganism/biodegradable polymer composite for decomposition of Formaldehyde. Journal of Polymers and the Environment, 22(3), 329-335. http://dx.doi.org/10.1007/s10924-014-0644-0.

http://dx.doi.org/10.1007/s10924-014-064...

] have evaluated formaldehyde bioremediation through the association of Aspergillus oryzae and poly(ε-caprolactone) (PCL). Other authors[4242 Baric, M., Pierro, L., Pietrangeli, B., & Papini, M. P. (2014). Polyhydroxyalkanoate (PHB) as a slow-release electron donor for advanced in situ bioremediation of chlorinated solvent-contaminated aquifers. New Biotechnology, 31(4), 377-382. http://dx.doi.org/10.1016/j.nbt.2013.10.008. PMid:24185077.

http://dx.doi.org/10.1016/j.nbt.2013.10....

] used polyhydroxyalkanoate as a slow release system for bioremediation of aquifers contaminated with chlorinated solvents, and[88 Caetano, R. M. J., Bedor, P. B. A., de Jesus, E. F. O., Leite, S. G. F., & Souza, F. G. Jr (2018). Oil biodegradation systems based on γ irradiated Poly (Butylene Succinate). Macromolecular Symposia, 380(1), 1800123. http://dx.doi.org/10.1002/masy.201800123.

http://dx.doi.org/10.1002/masy.201800123...

] studied the use of poly(butylene succinate) (PBS) as a nutrient-releasing system in the biodegradation of petroleum by Pseudomonas aeruginosa.

Some of the groups of polymers involved in the environmental area and some of its examples are shown in Figure 1. Polyesters[4343 Geeti, D. K., & Niranjan, K. (2019). Environmentally benign bio-based waterborne polyesters: Synthesis, thermal- and bio-degradation studies. Progress in Organic Coatings, 127, 419-428. http://dx.doi.org/10.1016/j.porgcoat.2018.11.034.

http://dx.doi.org/10.1016/j.porgcoat.201...

44 Liminana, P., Garcia-Sanoguera, D., Quiles-Carrillo, L., Balart, R., & Montanes, N. (2018). Development and characterization of environmentally friendly composites from poly(butylene succinate) (PBS) and almond shell flour with different compatibilizers. Composites. Part B, Engineering, 144, 153-162. http://dx.doi.org/10.1016/j.compositesb.2018.02.031.

http://dx.doi.org/10.1016/j.compositesb....

-4545 Figueiredo, A. S., Icart, L. P., Marques, F. D., Fernandes, E. R., Ferreira, L. P., Oliveira, G. E., & Souza, F. G. Jr (2019). Extrinsically magnetic poly(butylene succinate): an up-and-coming petroleum cleanup tool. The Science of the Total Environment, 647, 88-98. http://dx.doi.org/10.1016/j.scitotenv.2018.07.421. PMid:30077858.

http://dx.doi.org/10.1016/j.scitotenv.20...

], polyolefins[4646 Sarmah, P., & Rout, J. (2020). Role of algae and cyanobacteria in bioremediation: prospects in polyethylene biodegradation. In P. K. Singh, A. Kumar, V. K. Singh, A. K. Shrivastava. Advances in cyanobacterial biology (pp. 333-349). Cambridge: Elsevier. http://dx.doi.org/10.1016/B978-0-12-819311-2.00022-X

http://dx.doi.org/10.1016/B978-0-12-8193...

,4747 Wang, T., Yu, C., Chu, Q., Wang, F., Lan, T., & Wang, J. (2020). Adsorption behavior and mechanism of five pesticides on microplastics from agricultural polyethylene films. Chemosphere, 244, 125491. http://dx.doi.org/10.1016/j.chemosphere.2019.125491. PMid:31835051.

http://dx.doi.org/10.1016/j.chemosphere....

], polyamides[4848 Saiful Amran, S. N. B., Wongso, V., Abdul Halim, N. S., Husni, M. K., Sambudi, N. S., & Wirzal, M. D. H. (2019). Immobilized carbon-doped TiO 2 in polyamide fibers for the degradation of methylene blue. Journal of Asian Ceramic Societies, 7(3), 321-330. http://dx.doi.org/10.1080/21870764.2019.1636929.

http://dx.doi.org/10.1080/21870764.2019....

,4949 Ogunleye, A., Bhat, A., Irorere, V. U., Hill, D., Williams, C., & Radecka, I. (2015). Poly-γ-glutamic acid: production, properties and applications. Microbiology, 161(1), 1-17. http://dx.doi.org/10.1099/mic.0.081448-0. PMid:25288645.

http://dx.doi.org/10.1099/mic.0.081448-0...

], and polysaccharides[2828 Agostini de Moraes, M., Cocenza, D. S., Cruz Vasconcellos, F., Fraceto, L. F., & Beppu, M. M. (2013). Chitosan and alginate biopolymer membranes for remediation of contaminated water with herbicides. Journal of Environmental Management, 131, 222-227. http://dx.doi.org/10.1016/j.jenvman.2013.09.028. PMid:24178315.

http://dx.doi.org/10.1016/j.jenvman.2013...

,5050 Sun, Y., Chen, A., Pan, S.-Y., Sun, W., Zhu, C., Shah, K. J., & Zheng, H. (2019). Novel chitosan-based flocculants for chromium and nickle removal in wastewater via integrated chelation and flocculation. Journal of Environmental Management, 248, 109241. http://dx.doi.org/10.1016/j.jenvman.2019.07.012. PMid:31306928.

http://dx.doi.org/10.1016/j.jenvman.2019...

51 Alver, E., Metin, A. Ü., & Brouers, F. (2020). Methylene blue adsorption on magnetic alginate/rice husk bio-composite. International Journal of Biological Macromolecules, 154, 104-113. http://dx.doi.org/10.1016/j.ijbiomac.2020.02.330. PMid:32135251.

http://dx.doi.org/10.1016/j.ijbiomac.202...

-5252 Zhao, X., Wang, X., Song, G., & Lou, T. (2020). Microwave assisted copolymerization of sodium alginate and dimethyl diallyl ammonium chloride as flocculant for dye removal. International Journal of Biological Macromolecules, 156, 585-590. http://dx.doi.org/10.1016/j.ijbiomac.2020.04.054. PMid:32305372.

http://dx.doi.org/10.1016/j.ijbiomac.202...

] may be obtained naturally or through industrial chemical processes and are used in the removal or reduction of pollutants, among other applications in the environmental area, considering the advantages and disadvantages of each one for these applications.

Some classes of polymers applied in environmental area with their examples, advantages, and disadvantages.

The investigations on biopolymers seek efficient results about the biodegradability of these compounds, aiming to expand their application, which in recent years have apparently targeted bioremediation.

4. Bioremediation

With the purpose of restoring the balance between the biotic and abiotic factors of the impacted environment, technologies were developed using living organisms (e.g. bacteria, fungi, and plants) or enzymes present in them, with the ability to degrade pollutants, therefore reducing their release in the affected area[5353 Marchand, C., St-Arnaud, M., Hogland, W., Bell, T. H., & Hijri, M. (2017). Petroleum biodegradation capacity of bacteria and fungi isolated from petroleum-contaminated soil. International Biodeterioration & Biodegradation, 116, 48-57. http://dx.doi.org/10.1016/j.ibiod.2016.09.030.

http://dx.doi.org/10.1016/j.ibiod.2016.0...

,5454 Barnes, N. M., Khodse, V. B., Lotlikar, N. P., Meena, R. M., & Damare, S. R. (2018). Bioremediation potential of hydrocarbon-utilizing fungi from select marine niches of India. 3 Biotech, 8(1), 1-10. https://doi.org/10.1007/s13205-017-1043-8

https://doi.org/10.1007/s13205-017-1043-...

].

These technologies that make up bioremediation are environmental friendly, might be less expensive in some cases, and cause less impact to the environment when compared to technologies that use chemical and/or physical processes[5555 Li, P., Cai, Q., Lin, W., Chen, B., & Zhang, B. (2016). Offshore oil spill response practices and emerging challenges. Marine Pollution Bulletin, 110(1), 6-27. http://dx.doi.org/10.1016/j.marpolbul.2016.06.020. PMid:27393213.

http://dx.doi.org/10.1016/j.marpolbul.20...

,5656 Rodrigues, C., Núñez-Gómez, D., Silveira, D. D., Lapolli, F. R., & Lobo-Recio, M. A. (2019). Chitin as a substrate for the biostimulation of sulfate-reducing bacteria in the treatment of mine-impacted water (MIW). Journal of Hazardous Materials, 375, 330-338. http://dx.doi.org/10.1016/j.jhazmat.2019.02.086. PMid:30826155.

http://dx.doi.org/10.1016/j.jhazmat.2019...

]. In addition, bioremediation emerges as an alternative that may be applied both in situ (affected site) and ex situ, with bench scale tests for process optimization and subsequent in situ application. Among the possibilities of bioremediation application are natural attenuation, phytoremediation, composting, biostimulation, and bioaugmentation, among others[5757 Agnello, A. C., Bagard, M., van Hullebusch, E. D., Esposito, G., & Huguenot, D. (2016). Comparative bioremediation of heavy metals and petroleum hydrocarbons co-contaminated soil by natural attenuation, phytoremediation, bioaugmentation and bioaugmentation-assisted phytoremediation. The Science of the Total Environment, 563–564, 693-703. http://dx.doi.org/10.1016/j.scitotenv.2015.10.061. PMid:26524994.

http://dx.doi.org/10.1016/j.scitotenv.20...

58 Sánchez, Ó. J., Ospina, D. A., & Montoya, S. (2017). Compost supplementation with nutrients and microorganisms in composting process. Waste Management, 69, 136-153. http://dx.doi.org/10.1016/j.wasman.2017.08.012. PMid:28823698.

http://dx.doi.org/10.1016/j.wasman.2017....

-5959 Lee, D. W., Lee, H., Kwon, B.-O., Khim, J. S., Yim, U. H., Kim, B. S., & Kim, J.-J. (2018). Biosurfactant-assisted bioremediation of crude oil by indigenous bacteria isolated from Taean beach sediment. Environmental Pollution, 241, 254-264. http://dx.doi.org/10.1016/j.envpol.2018.05.070. PMid:29807284.

http://dx.doi.org/10.1016/j.envpol.2018....

].

Frequently, for a better effectiveness of the bioremediation process, biopolymers are used as tools, either in direct removal, as an auxiliary matrix, or even as an organic source in the minimization of environmental pollutants. In the case of biostimulation or bioaugmentation by nutrient and microorganism addition, respectively, biopolymers are present as physical barriers that prevent the immediate release of the pollutant in the area to be remedied, increasing the efficiency of pollutant biodegradation[66 Dzionek, A., Wojcieszyńska, D., & Guzik, U. (2016). Natural carriers in bioremediation: A review. Electronic Journal of Biotechnology, 23, 28-36. http://dx.doi.org/10.1016/j.ejbt.2016.07.003.

http://dx.doi.org/10.1016/j.ejbt.2016.07...

].

Table 1 presents some works related to the application of different biopolymers in bioremediation in the last two years.

Due to the impact of scientific advances on the above applications, there was an interest in searching for the most current works on the environmental area, with emphasis on bioremediation. For this purpose, the Foresight Methodology was adopted, as described in the next section.

5. Foresight Methodology

The main objective of prospecting technology monitoring is to inform the academic community and decision makers about what has been developed in the medium and long term in a certain field of expertise, based on what has been researched and carried out in a certain knowledge area. This helped to identify in which sectors certain products or techniques have a great potential of use or even of innovation[6767 Miles, I., Saritas, O., & Sokolov, A. (2016). Foresight for Science, Technology and Innovation. Cham: Springer International Publishing. http://dx.doi.org/10.1007/978-3-319-32574-3

http://dx.doi.org/10.1007/978-3-319-3257...

].

In this work, macro and meso level analyses of biopolymers and, specifically, of PBS, were performed from data obtained from the Scopus database containing scientific articles. For the patent documents, the international Lens patent database was used.

Their easy and free access to the academic community was the selection criteria for choosing these bases. The search strategy consisted of establishing a specific period between 2005 and 2019, in which there was an increase in the publication of patents worldwide. It should be noted that the survey did not include the current year, since there were not enough data for the entire 12-month period. The summaries and title of the patent and articles were investigated using the terms “biopolymers”, “green polymers”, “biodegradable polymers”, and “bioremediation”, with variations in the search field, using AND NOT to minimize duplication. The flowchart presenting the first steps of the foresight methodology may be seen in Figure 2.

Steps of the foresight methodology from polymers in general to the bioremediation application.

From a broader search on the Scopus database, considering the 15-year period, 17,147 scientific articles were found for biopolymers, 12,015 for biodegradable polymers, and 204 for green polymers. Based on these results, the five major areas of application are Chemistry, Materials Science, Engineering (including Chemical Engineering), Physics & Astronomy, and Biochemistry, Genetics & Molecular Biology. The environmental area represented 5.93% of the publications, considering the three categories of search. When the environmental bioremediation area is specified for biopolymers, biodegradable polymers, and green polymers, the number of publications declined to 199, 283 and 2, with a reduction of 98.84%, 97.65%, and 99.02%, respectively. However many of the publications belonged to the environmental area only due to the nature of the polymer, not because of its application.

A broad search, such as that made for the articles was carried out on the Lens patent basis, resulting in 90,031 patents for biopolymers, 99,608 for biodegradable polymers, and 519 for green polymers, considering the same terms and search period. Likewise, the search for these terms related to bioremediation generated a total of 736 patents for biopolymers, 175 for biodegradable polymers, and 1 for green polymers, indicating a reduction of 99.18%, 99.82%, and 99.81%, respectively, and evidencing the small number of papers about polymers in this area, specifically.

However, throughout this survey, the use of poly(butylene succinate) – PBS – appeared quite often (about 10% of citations). In this context, the PBS case study was encouraged.

6. A Specific Case: Poly(butylene succinate) – PBS

The poly(butylene succinate) – PBS is considered a biodegradable polymer partially derived from biological (petrochemical) processes[6868 Niaounakis, M. (2015). Biopolymers: applications and trends. Amsterdam: Elsevier Science.], as well as by the microbiological fermentation of renewable raw materials, such as glucose, xylose, and starch to obtain succinic acid and possibly a second monomer, 1,4-butanediol, from this acid or from petroleum derivatives[6969 Bechthold, I., Bretz, K., Kabasci, S., Kopitzky, R., & Springer, A. (2008). Succinic Acid: A New Platform Chemical for Biobased Polymers from Renewable Resources. Chemical Engineering & Technology, 31(5), 647-654. http://dx.doi.org/10.1002/ceat.200800063.

http://dx.doi.org/10.1002/ceat.200800063...

,7070 Xu, J., & Guo, B.-H. (2010). Poly(butylene succinate) and its copolymers: Research, development and industrialization. Biotechnology Journal, 5(11), 1149-1163. http://dx.doi.org/10.1002/biot.201000136. PMid:21058317.

http://dx.doi.org/10.1002/biot.201000136...

]. PBS is obtained by the transesterification reaction of 1,4-butanediol with succinic acid, followed by a polycondensation step with an increase in the size of the polymer chain and water release from the system as vapor[7070 Xu, J., & Guo, B.-H. (2010). Poly(butylene succinate) and its copolymers: Research, development and industrialization. Biotechnology Journal, 5(11), 1149-1163. http://dx.doi.org/10.1002/biot.201000136. PMid:21058317.

http://dx.doi.org/10.1002/biot.201000136...

].

PBS has been used in synthesis studies and production of food packaging[7171 Ferreira, L. P., Moreira, A. N., Pinto, J. C., & de Souza, F. G. Jr (2015). Synthesis of poly(butylene succinate) using metal catalysts. Polymer Engineering and Science, 55(8), 1889-1896. http://dx.doi.org/10.1002/pen.24029.

http://dx.doi.org/10.1002/pen.24029...

,7272 Siracusa, V., Lotti, N., Munari, A., & Dalla Rosa, M. (2015). Poly(butylene succinate) and poly(butylene succinate-co-adipate) for food packaging applications: gas barrier properties after stressed treatments. Polymer Degradation & Stability, 119, 35-45. http://dx.doi.org/10.1016/j.polymdegradstab.2015.04.026.

http://dx.doi.org/10.1016/j.polymdegrads...

], biomedical[7373 Gigli, M., Fabbri, M., Lotti, N., Gamberini, R., Rimini, B., & Munari, A. (2016). Poly(butylene succinate)-based polyesters for biomedical applications: A review. European Polymer Journal, 75, 431-460. http://dx.doi.org/10.1016/j.eurpolymj.2016.01.016.

http://dx.doi.org/10.1016/j.eurpolymj.20...

,7474 Pérez, D. D., Lunz, J. S. C., Santos, E. R. F., Oliveira, G. E., Jesus, E. F. O., & Souza, F. G. Jr (2017). Poly (Butylene Succinate) Scaffolds Prepared by Leaching. MOJ Polymer Science, 1(6). http://dx.doi.org/10.15406/mojps.2017.01.00035.

https://doi.org/10.15406/mojps.2017.01.0...

] and pharmaceutical[7575 Soares, D. Q. P., Souza, F. G. Jr, Freitas, R. B. V., Soares, V. P., Ferreira, L. P., Ramon, J. A., & Oliveira, G. E. (2017). Praziquantel Release Systems Based on Poly(Butylene Succinate)/Po lyethylene Glycol Nanocomposites. Current Applied Polymer Science, 1(1), 45-51. http://dx.doi.org/10.2174/2452271601666160922163508.

http://dx.doi.org/10.2174/24522716016661...

76 Miranda Sa, L. T., Vicosa, A. L., da Rocha, S. R. P., & de Souza, F. G. Jr (2018). Synthesis and characterization of Poly (Butylene Succinate)-G-Poly (Vinyl Acetate) as Ibuprofen drug delivery system. Current Applied Polymer Science, 1(2). http://dx.doi.org/10.2174/2452271601666170620125607.

http://dx.doi.org/10.2174/24522716016661...

77 Moraes, R. S. (2018). Synthesis of magnetic composite of poly (butylene succinate) and magnetite for the controlled release of meloxicam. MOJ Polymer Science, 2(1), 4. http://dx.doi.org/10.15406/mojps.2018.02.00044.

http://dx.doi.org/10.15406/mojps.2018.02...

-7878 Ramon, J., Saez, V., Gomes, F., Pinto, J., & Nele, M. (2018). Synthesis and characterization of PEG-PBS copolymers to obtain microspheres with different naproxen release profiles. Macromolecular Symposia, 380(1), 1800065. http://dx.doi.org/10.1002/masy.201800065.

http://dx.doi.org/10.1002/masy.201800065...

] products, but has gained prominence in the field of green chemistry as one of the most promising aliphatic polyesters due to its thermal properties, good processability, biodegradability, and easy application in composting[7979 Dvorackova, M., Svoboda, P., Kostka, L., & Pekarova, S. (2015). Influence of biodegradation in thermophilic anaerobic aqueous conditions on crystallization of poly(butylene succinate). Polymer Testing, 47, 59-70. http://dx.doi.org/10.1016/j.polymertesting.2015.08.006.

http://dx.doi.org/10.1016/j.polymertesti...

80 Thirunavukarasu, K., Purushothaman, S., Sridevi, J., Aarthy, M., Gowthaman, M. K., Nakajima-Kambe, T., & Kamini, N. R. (2016). Degradation of poly(butylene succinate) and poly(butylene succinate-co-butylene adipate) by a lipase from yeast Cryptococcus sp. grown on agro-industrial residues. International Biodeterioration & Biodegradation, 110, 99-107. http://dx.doi.org/10.1016/j.ibiod.2016.03.005.

http://dx.doi.org/10.1016/j.ibiod.2016.0...

-8181 Huang, Z., Qian, L., Yin, Q., Yu, N., Liu, T., & Tian, D. (2018). Biodegradability studies of poly(butylene succinate) composites filled with sugarcane rind fiber. Polymer Testing, 66, 319-326. http://dx.doi.org/10.1016/j.polymertesting.2018.02.003.

http://dx.doi.org/10.1016/j.polymertesti...

]. Some authors[8282 Zhu, S.-M., Deng, Y.-L., Ruan, Y.-J., Guo, X.-S., Shi, M.-M., & Shen, J.-Z. (2015). Biological denitrification using poly(butylene succinate) as carbon source and biofilm carrier for recirculating aquaculture system effluent treatment. Bioresource Technology, 192, 603-610. http://dx.doi.org/10.1016/j.biortech.2015.06.021. PMid:26093254.

http://dx.doi.org/10.1016/j.biortech.201...

,8383 Ruan, Y.-J., Deng, Y.-L., Guo, X.-S., Timmons, M. B., Lu, H.-F., Han, Z.-Y., Ye, Z. Y., Shi, M. M., & Zhu, S. M. (2016). Simultaneous ammonia and nitrate removal in an airlift reactor using poly(butylene succinate) as carbon source and biofilm carrier. Bioresource Technology, 216, 1004-1013. http://dx.doi.org/10.1016/j.biortech.2016.06.056. PMid:27343453.

http://dx.doi.org/10.1016/j.biortech.201...

] advocate the application of PBS in the environmental area, with research targeting the removal of excess nitrogenous nutrients in effluents, while[4545 Figueiredo, A. S., Icart, L. P., Marques, F. D., Fernandes, E. R., Ferreira, L. P., Oliveira, G. E., & Souza, F. G. Jr (2019). Extrinsically magnetic poly(butylene succinate): an up-and-coming petroleum cleanup tool. The Science of the Total Environment, 647, 88-98. http://dx.doi.org/10.1016/j.scitotenv.2018.07.421. PMid:30077858.

http://dx.doi.org/10.1016/j.scitotenv.20...

] addressing the physical removal of petroleum from the environment through the use of PBS with magnetic particles.

The main objective of this article is to investigate the research on the application of biodegradable polymers, especially PBS, on bioremediation in an international context.

In this case, the same foresight methodology was applied using the terms “poly(butylene succinate)” and “bioremediation” with variations in the search field, using AND NOT to minimize duplication. The second flowchart presenting the steps of foresight methodology about poly(butylene succinate) and its application is shown in Figure 3.

Steps of the foresight methodology to poly(butylene succinate) and its application on bioremediation.

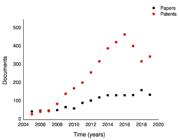

When searching for the term “poly(butylene succinate),” the number of patents and academic articles showed a gradual increase over time, with 1,484 articles and 3,657 patents from 2005 to the end of 2019, as shown in Figure 4. The rate increase was calculated from the trend line and presented approximately 8.74 articles and 30.63 patents per year, with R2 of 0.9187 and 0.8252, respectively. The highest number of patents is due to the sum of patents applied and granted. It was also possible to identify an increase of approximately 96.19% in the number of articles and 98.97% in the number of patents for this biodegradable polymer in the established period, indicating a significant increase in PBS application in different areas of knowledge. In 2018, there was a decrease in the number of patents granted (320) compared to the previous two years, which showed values of 404 patents in 2017 and 467 of this type of production in 2016. In 2019, this value was already increasing again with 346 patents and an upward trend for the following years. The graph also reveals a stabilization in the publication of articles in the last 6 years, which might be regarded, in a more optimistic view, as an opportunity for more investigations about this polymer.

Annual distribution of patent publications and academic articles on poly(butylene succinate) between 2005 and 2019. The annual distributions of papers are represented by (■) and patents by (●).

Regarding the areas of application of the PBS, the ones with the highest number of patents and articles were: Physics (51.8%) and Materials Science (32.7%), both with a high number of papers focusing on the characterization of the materials. In the graphs shown in Figures 55b, the areas of application of the PBS were studied in the period between 2005 and 2019, which exhibited a high number of articles and patents (including granted and applied patents), according to the classification of the databases consulted.

Distribution of (a) academic papers and (b) patents on poly(butylene succinate) by application area for the period between 2005 and 2019.

The analysis of these graphs revealed a low percentage of publications in the environmental area (3.0%), therefore suggesting a refinement of the search with the descriptors “poly(butylene succinate)” AND “bioremediation”, for a better understanding of this scenario. This last research yielded only 16 documents, and of the only two articles about the application of PBS in the environmental area, the one published in 2010[8484 Eubeler, J. P., Bernhard, M., & Knepper, T. P. (2010). Environmental biodegradation of synthetic polymers II. Biodegradation of different polymer groups. Trends in Analytical Chemistry, 29(1), 84-100. http://dx.doi.org/10.1016/j.trac.2009.09.005.

http://dx.doi.org/10.1016/j.trac.2009.09...

] deals with the environmental biodegradation of synthetic polymers, while the one from 2018[88 Caetano, R. M. J., Bedor, P. B. A., de Jesus, E. F. O., Leite, S. G. F., & Souza, F. G. Jr (2018). Oil biodegradation systems based on γ irradiated Poly (Butylene Succinate). Macromolecular Symposia, 380(1), 1800123. http://dx.doi.org/10.1002/masy.201800123.

http://dx.doi.org/10.1002/masy.201800123...

] evaluates the biodegradation of hydrocarbons with the use of the biodegradable already mentioned polymers. Patent prospecting revealed that of the 3,657 documents found for PBS use, only 11 were related in some way to bioremediation, although in the narrower search involving the CPC (Cooperative Patent Classification) classification, none of the patents found were directly related to bioremediation. The only links found were those related to surface coatings and composite synthesis.

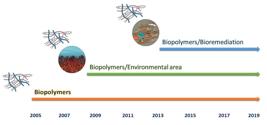

Based on the findings of the research in the area of biopolymers, the studies seek efficient results of the biodegradability of these compounds, aiming to expand their application, which in recent years apparently targets bioremediation, as shown in Figure 6.

Timeline with the advancement of biopolymer research, focusing on environmental and bioremediation in the last 15 years.

According to the research carried out in this study, in both bases analyzed, in the last 15 years there were few publications on the application of PBS in bioremediation, especially when the applied technique was biostimulation. The works with environmental application of PBS will be shown below.

The effect of dissolved oxygen on heterotrophic denitrification using poly(butylene succinate) as a carbon source and biofilm carrier was investigated in a recent work[8585 Luo, G., Li, L., Liu, Q., Xu, G., & Tan, H. (2014). Effect of dissolved oxygen on heterotrophic denitrification using poly(butylene succinate) as the carbon source and biofilm carrier. Bioresource Technology, 171, 152-158. http://dx.doi.org/10.1016/j.biortech.2014.08.055. PMid:25194264.

http://dx.doi.org/10.1016/j.biortech.201...

] in which the researchers evaluated the process under aeration, low aeration, and anoxic conditions, all in static batch, for 96 hours. The best nitrate and total nitrogen removal rates were identified at 65 hours of experiment under aerated condition, with values of 37.44 ± 0.24 and 36.24 ± 0.48 g.m3d-1, respectively. The authors concluded that the costs of the denitrification process using PBS as carbon source and biofilm carrier might be significantly reduced. The use of this polymer might also prevent effluent pretreatment.

Another study[8282 Zhu, S.-M., Deng, Y.-L., Ruan, Y.-J., Guo, X.-S., Shi, M.-M., & Shen, J.-Z. (2015). Biological denitrification using poly(butylene succinate) as carbon source and biofilm carrier for recirculating aquaculture system effluent treatment. Bioresource Technology, 192, 603-610. http://dx.doi.org/10.1016/j.biortech.2015.06.021. PMid:26093254.

http://dx.doi.org/10.1016/j.biortech.201...

] evaluated the use of PBS as a biofilm carrier and carbon source for treatment of the wastewater from aquaculture recirculation systems (RAS) wastewater in two reactors with 0‰ salinity and 25‰ salinity, respectively. The authors found high denitrification rates 0.53 ± 0.19 kg NO3-N. m-3.d-1 (0‰ salinity) and 0.66 ± 0.12 kg NO3-N. m-3. d-1 (25‰ salinity) and the nitrite concentration was maintained below 1 mg.L-1 in PBS solid-phase packing reactors for real RAS wastewater treatment. The salinity (25‰) parameter exhibited a more stable nitrate removal efficiency when changing operating conditions, causing adverse effects such as nitrate dissimilation to ammonia and the excess of dissolved organic carbon. The PBS degradation was demonstrated by SEM and FTIR analyses. The conclusion of the authors was that PBS showed great potential in the denitrification process, but needed further study on accurate carbon release for RAS practice.

In another study using PBS for bioremediation of industrial wastewaters[8686 an Duan, L., Li, C., Li, L., Yu, H., & Zhiying, H. (2016). Denitrification performance using biodegradable polymer as carbon source to treat nitrified swine wastwater. In 2016 ASABE International Meeting. St. Joseph: International Meeting, American Society of Agricultural and Biological Engineers. https://doi.org/10.13031/aim.20162462945

https://doi.org/10.13031/aim.20162462945...

], the effect of other biodegradable polymers like poly(hydroxybutyrate valerate) (PHBV), and poly(caprolactone) (PCL) was also assessed on the swine wastewater denitrification process. In this study, the authors used the polymers as biofilm carriers and carbon source and found that systems containing PCL presented a high denitrification efficiency (higher than 95%) in 20 days. On the other hand, PBS presented low nitrate removal at 30 days of experiment, with the highest removals on days 11 and 23, with a concentration similar to the initial one (37 mg.L-1) after reaching the maximum value of 54.7 mg.L-1 on the 8th and 19th days.

The biostimulation application was only addressed in a study carried out by a group[88 Caetano, R. M. J., Bedor, P. B. A., de Jesus, E. F. O., Leite, S. G. F., & Souza, F. G. Jr (2018). Oil biodegradation systems based on γ irradiated Poly (Butylene Succinate). Macromolecular Symposia, 380(1), 1800123. http://dx.doi.org/10.1002/masy.201800123.

http://dx.doi.org/10.1002/masy.201800123...

], in which microparticles were obtained from the fusion of PBS with urea and subsequent radiation for the application in the biostimulation test of Pseudomonas aeruginosa in order to remove Total Petroleum Hydrocarbons (TPH) in bench scale tests. This study resulted in 35.8% oil removal with microparticles irradiated with 25kGy after 30 days of testing.

Due to its physical characteristics and biodegradability[8080 Thirunavukarasu, K., Purushothaman, S., Sridevi, J., Aarthy, M., Gowthaman, M. K., Nakajima-Kambe, T., & Kamini, N. R. (2016). Degradation of poly(butylene succinate) and poly(butylene succinate-co-butylene adipate) by a lipase from yeast Cryptococcus sp. grown on agro-industrial residues. International Biodeterioration & Biodegradation, 110, 99-107. http://dx.doi.org/10.1016/j.ibiod.2016.03.005.

http://dx.doi.org/10.1016/j.ibiod.2016.0...

,8181 Huang, Z., Qian, L., Yin, Q., Yu, N., Liu, T., & Tian, D. (2018). Biodegradability studies of poly(butylene succinate) composites filled with sugarcane rind fiber. Polymer Testing, 66, 319-326. http://dx.doi.org/10.1016/j.polymertesting.2018.02.003.

http://dx.doi.org/10.1016/j.polymertesti...

,8787 Cho, H. S., Moon, H. S., Kim, M., Nam, K., & Kim, J. Y. (2011). Biodegradability and biodegradation rate of poly(caprolactone)-starch blend and poly(butylene succinate) biodegradable polymer under aerobic and anaerobic environment. Waste Management, 31(3), 475-480. http://dx.doi.org/10.1016/j.wasman.2010.10.029. PMid:21144726.

http://dx.doi.org/10.1016/j.wasman.2010....

,8888 Pan, W., Bai, Z., Su, T., & Wang, Z. (2018). Enzymatic degradation of poly(butylene succinate) with different molecular weights by cutinase. International Journal of Biological Macromolecules, 111, 1040-1046. http://dx.doi.org/10.1016/j.ijbiomac.2018.01.107. PMid:29366885.

http://dx.doi.org/10.1016/j.ijbiomac.201...

], PBS is potentially useful in the environmental area, mainly by reducing or removing pollutants from the environment, avoiding the compromise of the biotic community of the area. The choice of biodegradable polymers such as PBS for bioremediation processes is important since its occasional addition to the environment in an attempt to reduce damage, also enables this biodegradable polymer to act as a carbon source to the local microbiota. Therefore, it does not remaining in the environment for a long period of time. Another advantage of using PBS in bioremediation is the possibility of obtaining it from the transesterification reaction of monomers that might be acquired by microbiological fermentation of renewable raw materials such as glucose, xylose, and starch to obtain succinic acid[6969 Bechthold, I., Bretz, K., Kabasci, S., Kopitzky, R., & Springer, A. (2008). Succinic Acid: A New Platform Chemical for Biobased Polymers from Renewable Resources. Chemical Engineering & Technology, 31(5), 647-654. http://dx.doi.org/10.1002/ceat.200800063.

http://dx.doi.org/10.1002/ceat.200800063...

,7070 Xu, J., & Guo, B.-H. (2010). Poly(butylene succinate) and its copolymers: Research, development and industrialization. Biotechnology Journal, 5(11), 1149-1163. http://dx.doi.org/10.1002/biot.201000136. PMid:21058317.

http://dx.doi.org/10.1002/biot.201000136...

], therefore reducing the environmental impact yielded by the petrochemical sector.

7. Conclusions

The results showed scientific articles and patents, mainly for biopolymers and biodegradable polymers, in the period of 15 years. Biopolymers presented 17,147 articles and 90,031 patents, while biodegradable polymers presented 12,015 articles and 99,608 patents. The search for the major applications of these polymers and green polymers revealed that the five major areas are Chemistry, Materials Science, Engineering (including Chemical Engineering), Physics & Astronomy, and Biochemistry, Genetics & Molecular Biology. The low percentage of works in the Environmental area (approximately 6%) encouraged a more specific search for bioremediation, which showed percentages of reduction higher than 97% in both documentary sources.

The searches also revealed an upward trend on PBS use, with rates of 8.74 for articles and 30.63 for patents per year, although there is a stabilization in the number of articles in the last 6 years, a fact that might be seen as an opportunity for new publications. More studies were also identified regarding the application of PBS in the areas of Physics (51.8%) and Materials Science (32.7%) patent documents and articles, respectively. The use of this polymer was highlighted in processes of synthesis, characterization and application in the areas of chemistry, physics and pharmacy, mainly in the area of controlled release of medicines, which shows the potential application of this polymer in situations of absence of risk in different environments. However, for the main objective of this study and in the period evaluated, there was only 1 publication directly related to the use of PBS for bioremediation[88 Caetano, R. M. J., Bedor, P. B. A., de Jesus, E. F. O., Leite, S. G. F., & Souza, F. G. Jr (2018). Oil biodegradation systems based on γ irradiated Poly (Butylene Succinate). Macromolecular Symposia, 380(1), 1800123. http://dx.doi.org/10.1002/masy.201800123.

http://dx.doi.org/10.1002/masy.201800123...

], indicating a lack of research in this area and this may be useful for unpublished work and for a greater contribution to environmental recovery that not only affects the environmental sector, but also socioeconomic sectors.

8. Perspectives

Petroleum is still the largest source of raw material for the production of synthetic polymers, making them expensive compared to those obtained from natural sources. Modern society presents many materials that are obtained from renewable sources and, in the wake of technology, several studies point out to the use of natural biodegradable polymers. Among them, poly(butylene succinate) (PBS) may be obtained from petrochemical products, fermentation agro-industrial waste, or from other renewable sources[8989 Nanni, A., & Messori, M. (2020). Thermo-mechanical properties and creep modelling of wine lees filled Polyamide 11 (PA11) and Polybutylene succinate (PBS) bio-composites. Composites Science and Technology, 188, 107974. http://dx.doi.org/10.1016/j.compscitech.2019.107974.

http://dx.doi.org/10.1016/j.compscitech....

]. Although it presents both good processing and biodegradable properties, the widespread application of PBS is limited because it exhibits a highly linear chain structure that results in high crystallinity, high hydrophobicity, and low melt strength and viscosity[9090 Zhang, M., Li, Y., Wang, L., & Li, S. (2020). Compatibility and mechanical properties of gelatin‐filled polybutylene succinate composites. Journal of Applied Polymer Science, 137(29), 48881. http://dx.doi.org/10.1002/app.48881.

http://dx.doi.org/10.1002/app.48881...

]. Thus, the expansion of PBS use in several areas of application of biodegradable polymers depends on improvements in the processes of obtaining natural renewable sources in order to reduce the costs of the final product, as well as improvements in its thermomechanical properties. This is done by increasing molecular weight through polymer synthesis in the presence of effective catalysts; branching of the main chain; synthesis of co-polyesters; and addition of fillers, among other modifications[9191 Liu, P., Yue, X., He, G., Zhang, X., & Sun, Y. (2020). Influence of modified fiber-MHSH hybrids on fire hazards, combustion dynamics, and mechanical properties of flame‐retarded poly(butylene succinate) composites. Journal of Applied Polymer Science, 137(12), 48490. http://dx.doi.org/10.1002/app.48490.

http://dx.doi.org/10.1002/app.48490...

], therefore representing a sector with great potential for new studies and publications.

9. Acknowledgments

This study was partially funded by the Coordination for the Improvement of Higher Level Personnel - Brazil (CAPES – Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil) - Finance Code 001 and by the National Council for Scientific and Technological Development (CNPq – Conselho Nacional de Desenvolvimento Científico e Tecnológico).

-

How to cite: Bedor, P. B. A., Caetano, R. M. J., Souza Júnior, F. G., & Leite, S. G. F. (2020). Advances and perspectives in the use of polymers in the environmental area: a specific case of PBS in bioremediation. Polímeros: Ciência e Tecnologia, 30(2), e2020023. https://doi.org/10.1590/0104-1428.02220

10. References

-

1Patin, S. (2013). Environmental impact of crude oil spills. In S. Patin. Reference module in earth systems and environmental sciences Cambridge: Elsevier. http://dx.doi.org/10.1016/B978-0-12-409548-9.01221-5

» http://dx.doi.org/10.1016/B978-0-12-409548-9.01221-5 -

2Souza, E. C., Vessoni-Penna, T. C., & de Souza Oliveira, R. P. (2014). Biosurfactant-enhanced hydrocarbon bioremediation: an overview. International Biodeterioration & Biodegradation, 89, 88-94. http://dx.doi.org/10.1016/j.ibiod.2014.01.007

» http://dx.doi.org/10.1016/j.ibiod.2014.01.007 -

3Witzler, M., Alzagameem, A., Bergs, M., Khaldi-Hansen, B. E., Klein, S. E., Hielscher, D., Kamm, B., Kreyenschmidt, J., Tobiasch, E., & Schulze, M. (2018). Lignin-derived biomaterials for drug release and tissue engineering. Molecules, 23(8), 1885. http://dx.doi.org/10.3390/molecules23081885 PMid:30060536.

» http://dx.doi.org/10.3390/molecules23081885 -

4Mhlwatika, Z., & Aderibigbe, B. (2018). Polymeric nanocarriers for the delivery of antimalarials. Molecules (Basel, Switzerland), 23(10), 2527. http://dx.doi.org/10.3390/molecules23102527 PMid:30279405.

» http://dx.doi.org/10.3390/molecules23102527 -

5Reis, E. A., Rocha-Leão, M. H. M., & Leite, S. G. F. (2013). Slow-release nutrient capsules for microorganism stimulation in oil remediation. Applied Biochemistry and Biotechnology, 169(4), 1241-1249. http://dx.doi.org/10.1007/s12010-012-0022-0 PMid:23306878.

» http://dx.doi.org/10.1007/s12010-012-0022-0 -

6Dzionek, A., Wojcieszyńska, D., & Guzik, U. (2016). Natural carriers in bioremediation: A review. Electronic Journal of Biotechnology, 23, 28-36. http://dx.doi.org/10.1016/j.ejbt.2016.07.003

» http://dx.doi.org/10.1016/j.ejbt.2016.07.003 -

7Chaisorn, W., Prasertsan, P., O-Thong, S., & Methacanon, P. (2016). Production and characterization of biopolymer as bioflocculant from thermotolerant Bacillus subtilis WD161 in palm oil mill effluent. International Journal of Hydrogen Energy, 41(46), 21657-21664. http://dx.doi.org/10.1016/j.ijhydene.2016.06.045

» http://dx.doi.org/10.1016/j.ijhydene.2016.06.045 -

8Caetano, R. M. J., Bedor, P. B. A., de Jesus, E. F. O., Leite, S. G. F., & Souza, F. G. Jr (2018). Oil biodegradation systems based on γ irradiated Poly (Butylene Succinate). Macromolecular Symposia, 380(1), 1800123. http://dx.doi.org/10.1002/masy.201800123

» http://dx.doi.org/10.1002/masy.201800123 -

9Nič, M., Jirát, J., Košata, B., Jenkins, A., & McNaught, A. (2009). Compendium of chemical terminology: Gold Book (2.1.0.) Research Triagle Park, NC: IUPAC. https://doi.org/10.1351/goldbook

» https://doi.org/10.1351/goldbook -

10Doppalapudi, S., Jain, A., Khan, W., & Domb, A. J. (2014). Biodegradable polymers-an overview: BIODEGRADABLE POLYMERS. Polymers for Advanced Technologies, 25(5), 427-435. http://dx.doi.org/10.1002/pat.3305

» http://dx.doi.org/10.1002/pat.3305 -

11Hernández, N., Williams, R. C., & Cochran, E. W. (2014). The battle for the “green” polymer. Different approaches for biopolymer synthesis: Bioadvantaged vs. bioreplacement. Organic & Biomolecular Chemistry, 12(18), 2834-2849. http://dx.doi.org/10.1039/C3OB42339E PMid:24687118.

» http://dx.doi.org/10.1039/C3OB42339E -

12Vinod, A., Sanjay, M. R., Suchart, S., & Jyotishkumar, P. (2020). Renewable and sustainable biobased materials: an assessment on biofibers, biofilms, biopolymers and biocomposites. Journal of Cleaner Production, 258, 120978. http://dx.doi.org/10.1016/j.jclepro.2020.120978

» http://dx.doi.org/10.1016/j.jclepro.2020.120978 -

13Modi, V. K., Shrives, Y., Sharma, C., Sen, P. K., & Bohidar, S. K. (2007). Review on green polymer nanocomposite and their applications. International Journal of Innovative Research in Science, Engineering and Technology, 3, 17651-17656.

-

14Anderson, L. A., Islam, M. A., & Prather, K. L. J. (2018). Synthetic biology strategies for improving microbial synthesis of “green” biopolymers. The Journal of Biological Chemistry, 293(14), 5053-5061. http://dx.doi.org/10.1074/jbc.TM117.000368 PMid:29339554.

» http://dx.doi.org/10.1074/jbc.TM117.000368 -

15Velichko, N. S., Grinev, V. S., & Fedonenko, Y. P. (2020). Characterization of biopolymers produced by planktonic and biofilm cells of Herbaspirillum lusitanum P6-12. Journal of Applied Microbiology, jam.14647. http://dx.doi.org/10.1111/jam.14647 PMid:32216024.

» http://dx.doi.org/10.1111/jam.14647 -

16Xu, Y., Xu, J., Liu, D., Guo, B., & Xie, X. (2008). Synthesis and characterization of biodegradable poly(butylene succinate-co-propylene succinate)s. Journal of Applied Polymer Science, 109(3), 1881-1889. http://dx.doi.org/10.1002/app.24544

» http://dx.doi.org/10.1002/app.24544 -

17Rajan, K. P., Thomas, S. P., Gopanna, A., & Chavali, M. (2019). Polyhydroxybutyrate (PHB): A standout biopolymer for environmental sustainability. In L. M. T. Martínez, O. V. Kharissova, & B. I. Kharisov (Eds.), Handbook of ecomaterials (pp. 2803-2825). Cham: Springer International Publishing. http://dx.doi.org/10.1007/978-3-319-68255-6_92

» http://dx.doi.org/10.1007/978-3-319-68255-6_92 -

18Jaiswal, L., Shankar, S., & Rhim, J.-W. (2019). Applications of nanotechnology in food microbiology. In V. Gurtler, A. S. Ball, S. Soni. Methods in microbiology (Vol. 46, pp. 43-60). Cambridge: Elsevier. https://doi.org/10.1016/bs.mim.2019.03.002

» https://doi.org/10.1016/bs.mim.2019.03.002 -

19Islam, M., & Martinez-Duarte, R. (2017). A sustainable approach for tungsten carbide synthesis using renewable biopolymers. Ceramics International, 43(13), 10546-10553. http://dx.doi.org/10.1016/j.ceramint.2017.05.118

» http://dx.doi.org/10.1016/j.ceramint.2017.05.118 -

20Vetrik, M., Mattova, J., Mackova, H., Kucka, J., Pouckova, P., Kukackova, O., Brus, J., Eigner-Henke, S., Sedlacek, O., Sefc, L., Stepanek, P., & Hruby, M. (2018). Biopolymer strategy for the treatment of Wilson’s disease. Journal of Controlled Release, 273, 131-138. http://dx.doi.org/10.1016/j.jconrel.2018.01.026 PMid:29407674.

» http://dx.doi.org/10.1016/j.jconrel.2018.01.026 -

21Ceccacci, A. C., Chen, C.-H., Hwu, E.-T., Morelli, L., Bose, S., Bosco, F. G., & Boisen, A. (2017). Blu-Ray-based micromechanical characterization platform for biopolymer degradation assessment. Sensors and Actuators. B, Chemical, 241, 1303-1309. http://dx.doi.org/10.1016/j.snb.2016.09.190

» http://dx.doi.org/10.1016/j.snb.2016.09.190 -

22Lopez-Rubio, A., Fabra, M. J., Martinez-Sanz, M., Mendoza, S., & Vuong, Q. V. (2017). Biopolymer-based coatings and packaging structures for improved food quality. Journal of Food Quality, 1-2, 1-2. http://dx.doi.org/10.1155/2017/2351832

» http://dx.doi.org/10.1155/2017/2351832 -

23Moschakis, T., & Biliaderis, C. G. (2017). Biopolymer-based coacervates: Structures, functionality and applications in food products. Current Opinion in Colloid & Interface Science, 28, 96-109. http://dx.doi.org/10.1016/j.cocis.2017.03.006

» http://dx.doi.org/10.1016/j.cocis.2017.03.006 -

24Jung, E. Y., Jin, S. K., & Hur, S. J. (2018). Analysis of the effects of biopolymer encapsulation and sodium replacement combination technology on the quality characteristics and inhibition of sodium absorption from sausage in mice. Food Chemistry, 250, 197-203. http://dx.doi.org/10.1016/j.foodchem.2018.01.065 PMid:29412911.

» http://dx.doi.org/10.1016/j.foodchem.2018.01.065 -

25Park, S.-B., Lih, E., Park, K.-S., Joung, Y. K., & Han, D. K. (2017). Biopolymer-based functional composites for medical applications. Progress in Polymer Science, 68, 77-105. http://dx.doi.org/10.1016/j.progpolymsci.2016.12.003

» http://dx.doi.org/10.1016/j.progpolymsci.2016.12.003 -

26Singh, B. G., Das, R. P., & Kunwar, A. (2019). Protein: a versatile biopolymer for the fabrication of smart materials for drug delivery. Journal of Chemical Sciences, 131(9), 91. http://dx.doi.org/10.1007/s12039-019-1671-0

» http://dx.doi.org/10.1007/s12039-019-1671-0 -

27Sithole, M. N., Choonara, Y. E., du Toit, L. C., Kumar, P., Marimuthu, T., Kondiah, P. P. D., & Pillay, V. (2018). Development of a novel Polymeric Nanocomposite complex for drugs with low bioavailability. AAPS PharmSciTech, 19(1), 303-314. http://dx.doi.org/10.1208/s12249-017-0796-z PMid:28717975.

» http://dx.doi.org/10.1208/s12249-017-0796-z -

28Agostini de Moraes, M., Cocenza, D. S., Cruz Vasconcellos, F., Fraceto, L. F., & Beppu, M. M. (2013). Chitosan and alginate biopolymer membranes for remediation of contaminated water with herbicides. Journal of Environmental Management, 131, 222-227. http://dx.doi.org/10.1016/j.jenvman.2013.09.028 PMid:24178315.

» http://dx.doi.org/10.1016/j.jenvman.2013.09.028 -

29Song, W., Gao, B., Xu, X., Xing, L., Han, S., Duan, P., Song, W., & Jia, R. (2016). Adsorption-desorption behavior of magnetic amine/Fe3O4 functionalized biopolymer resin towards anionic dyes from wastewater. Bioresource Technology, 210, 123-130. http://dx.doi.org/10.1016/j.biortech.2016.01.078 PMid:26852273.

» http://dx.doi.org/10.1016/j.biortech.2016.01.078 -

30Narayanan, N., Gupta, S., Gajbhiye, V. T., & Manjaiah, K. M. (2017). Optimization of isotherm models for pesticide sorption on biopolymer-nanoclay composite by error analysis. Chemosphere, 173, 502-511. http://dx.doi.org/10.1016/j.chemosphere.2017.01.084 PMid:28131920.

» http://dx.doi.org/10.1016/j.chemosphere.2017.01.084 -

31El Asjadi, S., Nederpel, Q. A., Cotiuga, I. M., Picken, S. J., Besseling, N. A. M., Mendes, E., & Lommerts, B. J. (2018). Biopolymer scleroglucan as an emulsion stabilizer. Colloids and Surfaces. A, Physicochemical and Engineering Aspects, 546, 326-333. http://dx.doi.org/10.1016/j.colsurfa.2018.02.035

» http://dx.doi.org/10.1016/j.colsurfa.2018.02.035 -

32Song, W., Gao, B., Wang, H., Xu, X., Xue, M., Zha, M., & Gong, B. (2017). The rapid adsorption-microbial reduction of perchlorate from aqueous solution by novel amine-crosslinked magnetic biopolymer resin. Bioresource Technology, 240, 68-76. http://dx.doi.org/10.1016/j.biortech.2017.03.064 PMid:28341379.

» http://dx.doi.org/10.1016/j.biortech.2017.03.064 -

33Lopez-Pena, C. L., & McClements, D. J. (2015). Impact of a food-grade cationic biopolymer (ε-polylysine) on the digestion of emulsified lipids: in vitro study. Food Research International, 75, 34-40. http://dx.doi.org/10.1016/j.foodres.2015.05.025 PMid:28454965.

» http://dx.doi.org/10.1016/j.foodres.2015.05.025 -

34La Mantia, F. P., Ceraulo, M., Mistretta, M. C., & Morreale, M. (2018). Rheological behaviour, mechanical properties and processability of biodegradable polymer systems for film blowing. Journal of Polymers and the Environment, 26(2), 749-755. http://dx.doi.org/10.1007/s10924-017-0995-4

» http://dx.doi.org/10.1007/s10924-017-0995-4 -

35Hsu, S.-T., & Yao, Y. L. (2013). Effect of drug loading and laser surface melting on drug release profile from biodegradable polymer. Journal of Applied Polymer Science, 130(6), 4147-4156. https://doi.org/10.1002/app.39664

» https://doi.org/10.1002/app.39664 -

36Tan, L., Jiang, T., Yang, X., Li, W., Pan, L., & Yu, M. (2015). Core-shell biopolymer microspheres for sustained drug release. Journal of Applied Polymer Science, 132(14). https://doi.org/10.1002/app.41782

» https://doi.org/10.1002/app.41782 -

37Rizzarelli, P., & Carroccio, S. (2014). Modern mass spectrometry in the characterization and degradation of biodegradable polymers. Analytica Chimica Acta, 808, 18-43. http://dx.doi.org/10.1016/j.aca.2013.11.001 PMid:24370091.

» http://dx.doi.org/10.1016/j.aca.2013.11.001 -

38Ding, M., Zhang, M., Yang, J., & Qiu, J.-H. (2012). Study on the enzymatic degradation of aliphatic polyester-PBS and its copolymers. Journal of Applied Polymer Science, 124(4), 2902-2907. http://dx.doi.org/10.1002/app.35347

» http://dx.doi.org/10.1002/app.35347 -

39Song, W., Gao, B., Xu, X., Wang, F., Xue, N., Sun, S., Song, W., & Jia, R. (2016). Adsorption of nitrate from aqueous solution by magnetic amine-crosslinked biopolymer based corn stalk and its chemical regeneration property. Journal of Hazardous Materials, 304, 280-290. http://dx.doi.org/10.1016/j.jhazmat.2015.10.073 PMid:26561752.

» http://dx.doi.org/10.1016/j.jhazmat.2015.10.073 -

40Wilton, N., Lyon-Marion, B. A., Kamath, R., McVey, K., Pennell, K. D., & Robbat, A. Jr (2018). Remediation of heavy hydrocarbon impacted soil using biopolymer and polystyrene foam beads. Journal of Hazardous Materials, 349, 153-159. http://dx.doi.org/10.1016/j.jhazmat.2018.01.041 PMid:29414747.

» http://dx.doi.org/10.1016/j.jhazmat.2018.01.041 -

41Tanida, I., Sakaue, A., & Osawa, S. (2014). Development of a safe solid-state microorganism/biodegradable polymer composite for decomposition of Formaldehyde. Journal of Polymers and the Environment, 22(3), 329-335. http://dx.doi.org/10.1007/s10924-014-0644-0

» http://dx.doi.org/10.1007/s10924-014-0644-0 -

42Baric, M., Pierro, L., Pietrangeli, B., & Papini, M. P. (2014). Polyhydroxyalkanoate (PHB) as a slow-release electron donor for advanced in situ bioremediation of chlorinated solvent-contaminated aquifers. New Biotechnology, 31(4), 377-382. http://dx.doi.org/10.1016/j.nbt.2013.10.008 PMid:24185077.

» http://dx.doi.org/10.1016/j.nbt.2013.10.008 -

43Geeti, D. K., & Niranjan, K. (2019). Environmentally benign bio-based waterborne polyesters: Synthesis, thermal- and bio-degradation studies. Progress in Organic Coatings, 127, 419-428. http://dx.doi.org/10.1016/j.porgcoat.2018.11.034

» http://dx.doi.org/10.1016/j.porgcoat.2018.11.034 -

44Liminana, P., Garcia-Sanoguera, D., Quiles-Carrillo, L., Balart, R., & Montanes, N. (2018). Development and characterization of environmentally friendly composites from poly(butylene succinate) (PBS) and almond shell flour with different compatibilizers. Composites. Part B, Engineering, 144, 153-162. http://dx.doi.org/10.1016/j.compositesb.2018.02.031

» http://dx.doi.org/10.1016/j.compositesb.2018.02.031 -

45Figueiredo, A. S., Icart, L. P., Marques, F. D., Fernandes, E. R., Ferreira, L. P., Oliveira, G. E., & Souza, F. G. Jr (2019). Extrinsically magnetic poly(butylene succinate): an up-and-coming petroleum cleanup tool. The Science of the Total Environment, 647, 88-98. http://dx.doi.org/10.1016/j.scitotenv.2018.07.421 PMid:30077858.

» http://dx.doi.org/10.1016/j.scitotenv.2018.07.421 -

46Sarmah, P., & Rout, J. (2020). Role of algae and cyanobacteria in bioremediation: prospects in polyethylene biodegradation. In P. K. Singh, A. Kumar, V. K. Singh, A. K. Shrivastava. Advances in cyanobacterial biology (pp. 333-349). Cambridge: Elsevier. http://dx.doi.org/10.1016/B978-0-12-819311-2.00022-X

» http://dx.doi.org/10.1016/B978-0-12-819311-2.00022-X -

47Wang, T., Yu, C., Chu, Q., Wang, F., Lan, T., & Wang, J. (2020). Adsorption behavior and mechanism of five pesticides on microplastics from agricultural polyethylene films. Chemosphere, 244, 125491. http://dx.doi.org/10.1016/j.chemosphere.2019.125491 PMid:31835051.

» http://dx.doi.org/10.1016/j.chemosphere.2019.125491 -

48Saiful Amran, S. N. B., Wongso, V., Abdul Halim, N. S., Husni, M. K., Sambudi, N. S., & Wirzal, M. D. H. (2019). Immobilized carbon-doped TiO 2 in polyamide fibers for the degradation of methylene blue. Journal of Asian Ceramic Societies, 7(3), 321-330. http://dx.doi.org/10.1080/21870764.2019.1636929

» http://dx.doi.org/10.1080/21870764.2019.1636929 -

49Ogunleye, A., Bhat, A., Irorere, V. U., Hill, D., Williams, C., & Radecka, I. (2015). Poly-γ-glutamic acid: production, properties and applications. Microbiology, 161(1), 1-17. http://dx.doi.org/10.1099/mic.0.081448-0 PMid:25288645.

» http://dx.doi.org/10.1099/mic.0.081448-0 -

50Sun, Y., Chen, A., Pan, S.-Y., Sun, W., Zhu, C., Shah, K. J., & Zheng, H. (2019). Novel chitosan-based flocculants for chromium and nickle removal in wastewater via integrated chelation and flocculation. Journal of Environmental Management, 248, 109241. http://dx.doi.org/10.1016/j.jenvman.2019.07.012 PMid:31306928.

» http://dx.doi.org/10.1016/j.jenvman.2019.07.012 -

51Alver, E., Metin, A. Ü., & Brouers, F. (2020). Methylene blue adsorption on magnetic alginate/rice husk bio-composite. International Journal of Biological Macromolecules, 154, 104-113. http://dx.doi.org/10.1016/j.ijbiomac.2020.02.330 PMid:32135251.

» http://dx.doi.org/10.1016/j.ijbiomac.2020.02.330 -

52Zhao, X., Wang, X., Song, G., & Lou, T. (2020). Microwave assisted copolymerization of sodium alginate and dimethyl diallyl ammonium chloride as flocculant for dye removal. International Journal of Biological Macromolecules, 156, 585-590. http://dx.doi.org/10.1016/j.ijbiomac.2020.04.054 PMid:32305372.

» http://dx.doi.org/10.1016/j.ijbiomac.2020.04.054 -

53Marchand, C., St-Arnaud, M., Hogland, W., Bell, T. H., & Hijri, M. (2017). Petroleum biodegradation capacity of bacteria and fungi isolated from petroleum-contaminated soil. International Biodeterioration & Biodegradation, 116, 48-57. http://dx.doi.org/10.1016/j.ibiod.2016.09.030

» http://dx.doi.org/10.1016/j.ibiod.2016.09.030 -

54Barnes, N. M., Khodse, V. B., Lotlikar, N. P., Meena, R. M., & Damare, S. R. (2018). Bioremediation potential of hydrocarbon-utilizing fungi from select marine niches of India. 3 Biotech, 8(1), 1-10. https://doi.org/10.1007/s13205-017-1043-8

» https://doi.org/10.1007/s13205-017-1043-8 -

55Li, P., Cai, Q., Lin, W., Chen, B., & Zhang, B. (2016). Offshore oil spill response practices and emerging challenges. Marine Pollution Bulletin, 110(1), 6-27. http://dx.doi.org/10.1016/j.marpolbul.2016.06.020 PMid:27393213.

» http://dx.doi.org/10.1016/j.marpolbul.2016.06.020 -

56Rodrigues, C., Núñez-Gómez, D., Silveira, D. D., Lapolli, F. R., & Lobo-Recio, M. A. (2019). Chitin as a substrate for the biostimulation of sulfate-reducing bacteria in the treatment of mine-impacted water (MIW). Journal of Hazardous Materials, 375, 330-338. http://dx.doi.org/10.1016/j.jhazmat.2019.02.086 PMid:30826155.

» http://dx.doi.org/10.1016/j.jhazmat.2019.02.086 -

57Agnello, A. C., Bagard, M., van Hullebusch, E. D., Esposito, G., & Huguenot, D. (2016). Comparative bioremediation of heavy metals and petroleum hydrocarbons co-contaminated soil by natural attenuation, phytoremediation, bioaugmentation and bioaugmentation-assisted phytoremediation. The Science of the Total Environment, 563–564, 693-703. http://dx.doi.org/10.1016/j.scitotenv.2015.10.061 PMid:26524994.

» http://dx.doi.org/10.1016/j.scitotenv.2015.10.061 -

58Sánchez, Ó. J., Ospina, D. A., & Montoya, S. (2017). Compost supplementation with nutrients and microorganisms in composting process. Waste Management, 69, 136-153. http://dx.doi.org/10.1016/j.wasman.2017.08.012 PMid:28823698.

» http://dx.doi.org/10.1016/j.wasman.2017.08.012 -

59Lee, D. W., Lee, H., Kwon, B.-O., Khim, J. S., Yim, U. H., Kim, B. S., & Kim, J.-J. (2018). Biosurfactant-assisted bioremediation of crude oil by indigenous bacteria isolated from Taean beach sediment. Environmental Pollution, 241, 254-264. http://dx.doi.org/10.1016/j.envpol.2018.05.070 PMid:29807284.

» http://dx.doi.org/10.1016/j.envpol.2018.05.070 -

60Sheu, Y.-T., Tsang, D. C. W., Dong, C.-D., Chen, C.-W., Luo, S.-G., & Kao, C.-M. (2018). Enhanced bioremediation of TCE-contaminated groundwater using gamma poly-glutamic acid as the primary substrate. Journal of Cleaner Production, 178, 108-118. http://dx.doi.org/10.1016/j.jclepro.2017.12.212

» http://dx.doi.org/10.1016/j.jclepro.2017.12.212 -

61Farber, R., Dabush-Busheri, I., Chaniel, G., Rozenfeld, S., Bormashenko, E., Multanen, V., & Cahan, R. (2019). Biofilm grown on wood waste pretreated with cold low-pressure nitrogen plasma: utilization for toluene remediation. International Biodeterioration & Biodegradation, 139, 62-69. http://dx.doi.org/10.1016/j.ibiod.2019.03.003

» http://dx.doi.org/10.1016/j.ibiod.2019.03.003 -

62Ismail, A. S., El-Sheshtawy, H. S., & Khalil, N. M. (2019). Bioremediation process of oil spill using fatty-lignocellulose sawdust and its enhancement effect. Egyptian Journal of Petroleum, 28(2), 205-211. http://dx.doi.org/10.1016/j.ejpe.2019.03.002

» http://dx.doi.org/10.1016/j.ejpe.2019.03.002 -

63San Keskin, N. O., Celebioglu, A., Sarioglu, O. F., Uyar, T., & Tekinay, T. (2018). Encapsulation of living bacteria in electrospun cyclodextrin ultrathin fibers for bioremediation of heavy metals and reactive dye from wastewater. Colloids and Surfaces. B, Biointerfaces, 161, 169-176. http://dx.doi.org/10.1016/j.colsurfb.2017.10.047 PMid:29078166.

» http://dx.doi.org/10.1016/j.colsurfb.2017.10.047 -

64Patowary, R., Patowary, K., Kalita, M. C., & Deka, S. (2018). Application of biosurfactant for enhancement of bioremediation process of crude oil contaminated soil. International Biodeterioration & Biodegradation, 129, 50-60. http://dx.doi.org/10.1016/j.ibiod.2018.01.004

» http://dx.doi.org/10.1016/j.ibiod.2018.01.004 -