Abstract

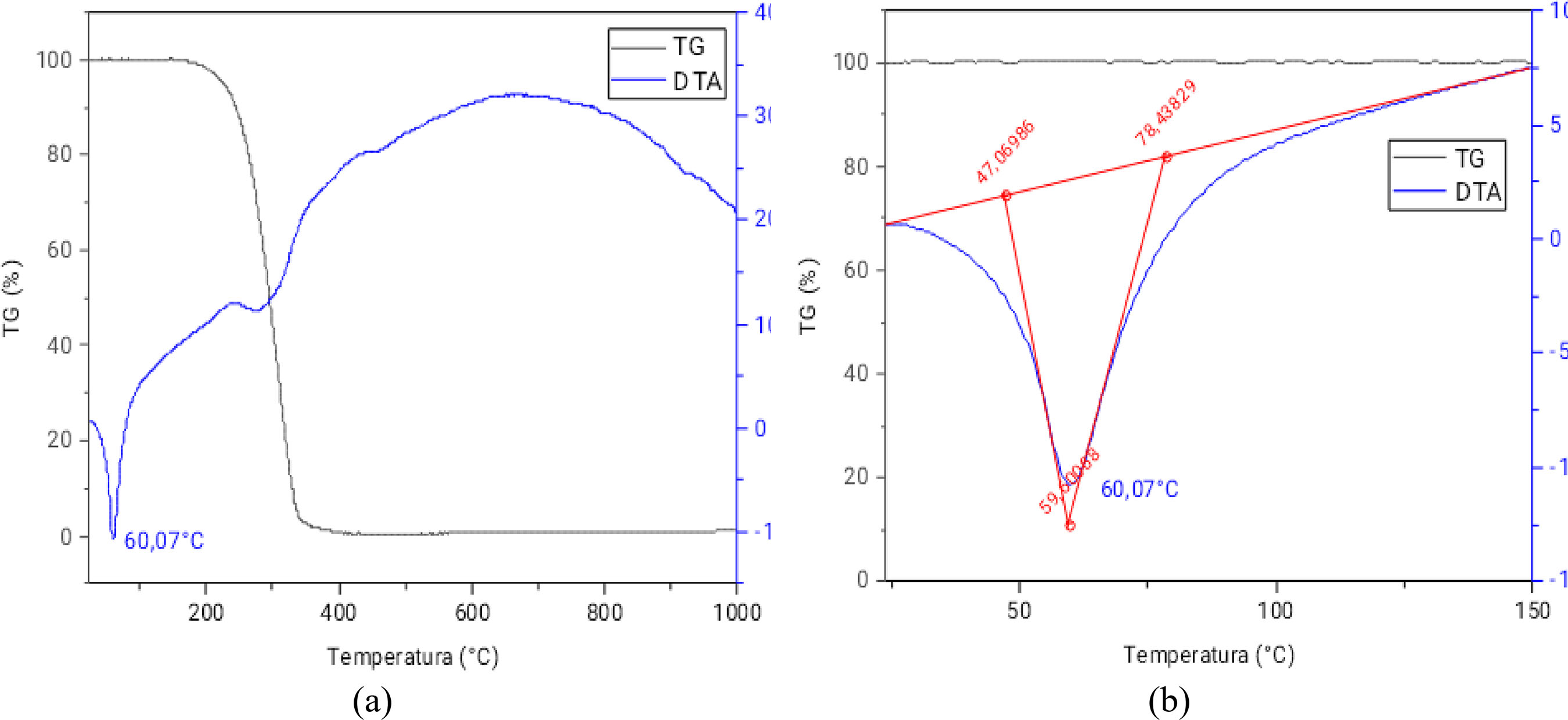

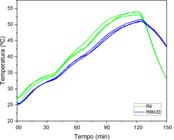

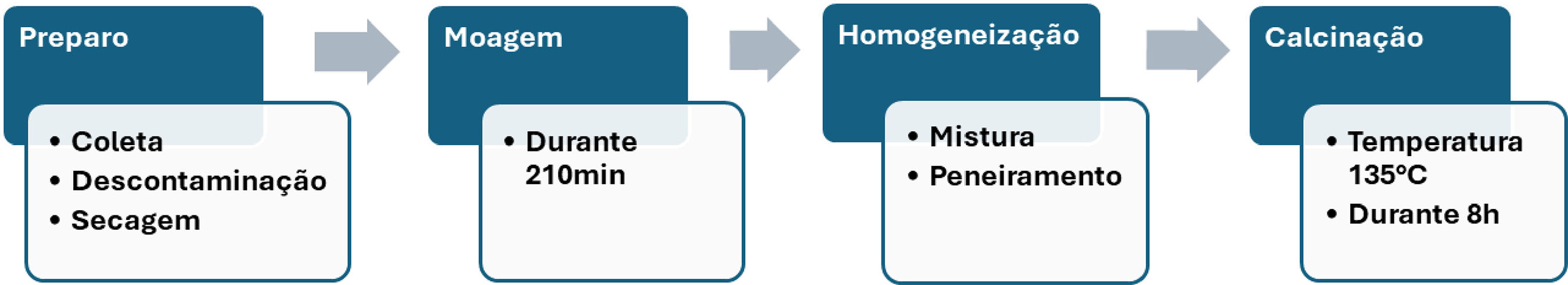

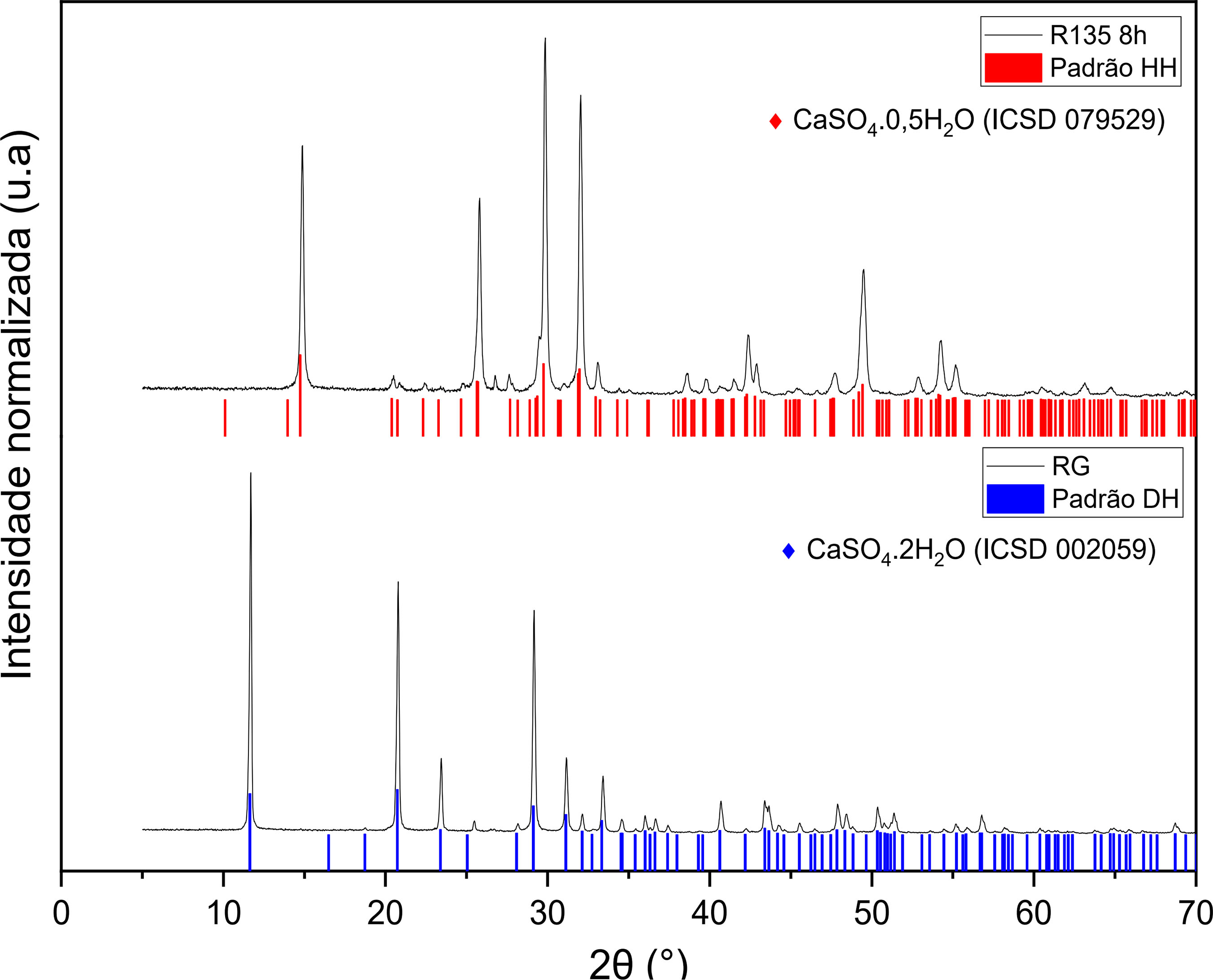

In this work, solid and liquid paraffins were mixed to adjust the melting point for use as a phase change material (PCM) in thermal regulation of buildings. The MMF was microencapsulated by suspension in a polymeric coating of polyvinyl alcohol. To incorporate 10% and 20% of the microspheres, recycled gypsum waste was used as the construction material. The conversion of the gypsum residue (CaSO4·2H2O) into binder (CaSO4·0.5H2O) was confirmed by X-ray diffraction. Differential thermal analysis and thermogravimetry established standards for the conversion and revealed thermal characteristics of the microspheres, such as thermal stability and melting temperature. Scanning electron microscopy identified the encapsulation of the microspheres and their distribution in the matrix, with agglomerations. In the fresh state, the microspheres accelerated the onset time of setting. After hardening, a reduction in surface hardness of up to 60.4% and in compressive strength of 56.7% was observed, in relation to the reference. Thermal performance was promising, demonstrating a delay in the temperature rise when heated and a reduction when cooled. The temperature difference between the composite and the recycled gypsum residue was 3.8 °C when heated and 10 °C when cooled.

Keywords

Thermal regulation; Phase change material; Gypsum residue

Microencapsulated paraffin with polyvinyl alcohol incorporated into a sustainable matrix for thermal regulation of buildings

Microencapsulated paraffin with polyvinyl alcohol incorporated into a sustainable matrix for thermal regulation of buildings Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Thumbnail

Fonte:

Fonte:  Fonte:

Fonte: