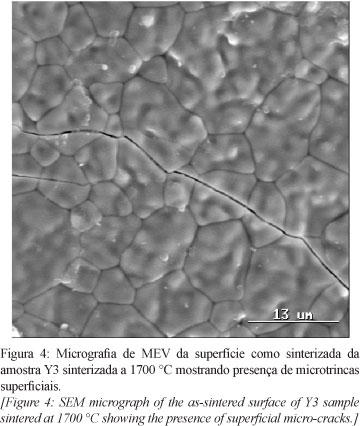

Verificou-se a possibilidade de se produzir cerâmica de zircônia parcialmente estabilizada (PSZ) utilizando um pó de zircônia monoclínica comercial com a adição de MgO, Y2O3 e/ou CaO por meio de mistura mecânica de pós. A metodologia adotada visou primordialmente diminuir o custo da matéria-prima. Foram preparadas amostras de PSZ na forma de cilindros com adições individuais e com misturas de aditivos em sinterizações entre 1500 e 1700 °C no campo binário tetragonal-cúbica. As amostras foram usinadas em retificadora cilíndrica e submetidas ao ensaio de rugosidade. Também foram determinadas as fases presentes (difração de raios X, método de Rietveld), a microestrutura (microscopia eletrônica de varredura), a densidade/porosidade, a dureza Vickers, a tenacidade à fratura e a resistência à flexão biaxial. Em geral, a melhor temperatura de sinterização foi 1500 °C. As melhores composições foram uma com adição simples de MgO e três composições mistas contendo Y2O3. As características destas amostras sinterizadas a 1500 °C foram próximas às de um pó comercial pré-aditivado com MgO (Mg-PSZ) sinterizado a 1700 °C.

zircônia; aditivo; processamento; propriedades mecânicas; sinterização