Abstracts

It was compared the performance of the metering mechanism of corn seeds (Zea mays) in direct seeding in an area of 200 ha, a property in Piraí do Sul, State of Paraná - PR, in Brazil. It was seeded 4 maize hybrids, 50 ha of each, with seeds of different sieves. The experiment was conducted in a randomized block design (RBD), with 3 treatments and 9 repetitions for each corn hybrid. The treatments were the pneumatic seed of metering mechanisms, horizontal perforated disc with and without ramp®. The plots were 40 m² and were distributed at the early, middle and late sowing. The variables analyzed in each corn hybrid were initial population, faulty spacing, multiple spacing, acceptable spacing, and yield components. As there were no significant differences in the variables, it was concluded that the quality of seeding with different systems of distribution was similar in the different sieves of distributed corn seeds.

pneumatic system; horizontal seed plate; disc with ramp®

Comparou-se o desempenho dos mecanismos dosadores de sementes de milho (Zea mays) em semeadura direta, numa área de 200 ha, numa propriedade do município de Piraí do Sul - PR. Semearam-se quatro híbridos de milho, 50 ha cada, com sementes de peneiras distintas. O experimento foi conduzido no delineamento em blocos ao acaso (DBC), sendo três tratamentos e nove repetições para cada híbrido de milho. Os tratamentos consistiram nos mecanismos dosadores de sementes pneumáticos, disco perfurado horizontal com e sem rampa®. As parcelas tinham 40 m² e foram distribuídas no início, meio e final da semeadura. As variáveis analisadas em cada híbrido de milho foram: população inicial, espaçamentos falhos, espaçamentos múltiplos, espaçamentos aceitáveis e os componentes de rendimento. Como não houve diferenças significativas nas variáveis analisadas, concluiu-se que a qualidade de semeadura com diferentes sistemas de distribuição foi semelhante nas distintas peneiras de sementes de milho distribuídas.

sistema pneumático; disco perfurado horizontal; disco com rampa®

TECHNICAL PAPERS

AGRICULTURAL MACHINERY MANAGEMENT

Comparison of metering mechanisms of corn seed

Comparação entre mecanismos dosadores de sementes de milho

Pedro H. Weirich NetoI; Altair JustinoII; Rodrigo T. NamurIII; José DominguesIV; Luiz C. GarciaV

IEngº Agrícola, Prof. Doutor, Universidade Estadual de Ponta Grossa - PR, Departamento de Ciências do Solo e Engenharia Agrícola, Fone: (0xx42) 3220 3090, lama1@uepg.br

IIEngº Agrônomo, Prof. Doutor, Universidade Estadual de Ponta Grossa - PR, Departamento de Ciências do Solo e Engenharia Agrícola

IIIEngº Agrônomo, Castrolanda

IVEngº Agrônomo, Forterra

VEngº Agrônomo, Prof. Doutor, Universidade Estadual de Ponta Grossa - PR, Departamento de Ciências do Solo e Engenharia Agrícola

ABSTRACT

It was compared the performance of the metering mechanism of corn seeds (Zea mays) in direct seeding in an area of 200 ha, a property in Piraí do Sul, State of Paraná - PR, in Brazil. It was seeded 4 maize hybrids, 50 ha of each, with seeds of different sieves. The experiment was conducted in a randomized block design (RBD), with 3 treatments and 9 repetitions for each corn hybrid. The treatments were the pneumatic seed of metering mechanisms, horizontal perforated disc with and without ramp®. The plots were 40 m2 and were distributed at the early, middle and late sowing. The variables analyzed in each corn hybrid were initial population, faulty spacing, multiple spacing, acceptable spacing, and yield components. As there were no significant differences in the variables, it was concluded that the quality of seeding with different systems of distribution was similar in the different sieves of distributed corn seeds.

Keywords: pneumatic system, horizontal seed plate, disc with ramp®.

RESUMO

Comparou-se o desempenho dos mecanismos dosadores de sementes de milho (Zea mays) em semeadura direta, numa área de 200 ha, numa propriedade do município de Piraí do Sul - PR. Semearam-se quatro híbridos de milho, 50 ha cada, com sementes de peneiras distintas. O experimento foi conduzido no delineamento em blocos ao acaso (DBC), sendo três tratamentos e nove repetições para cada híbrido de milho. Os tratamentos consistiram nos mecanismos dosadores de sementes pneumáticos, disco perfurado horizontal com e sem rampa®. As parcelas tinham 40 m2 e foram distribuídas no início, meio e final da semeadura. As variáveis analisadas em cada híbrido de milho foram: população inicial, espaçamentos falhos, espaçamentos múltiplos, espaçamentos aceitáveis e os componentes de rendimento. Como não houve diferenças significativas nas variáveis analisadas, concluiu-se que a qualidade de semeadura com diferentes sistemas de distribuição foi semelhante nas distintas peneiras de sementes de milho distribuídas.

Palavras-chave: sistema pneumático, disco perfurado horizontal, disco com rampa®.

INTRODUCTION

Among the cereals grown in Brazil, corn stands out, with about 56.3 million tons of grain produced in an area of approximately 13.7 million hectares (CONAB, 2011). Corn does not have an effective mechanism to compensate for gaps in the crop; thus, the seeding process has special attention of the farmer in order to ensure the population needed to achieve higher productivity and profitability (SANGOI et al., 2009).

The sowing is performed by a seeder, which must distribute the seeds to ensure germination. The seeder for direct seeding performs the function of straw cut, furrowing, seed deposition, and furrow closing. When it distributes seeds, one by one, in predetermined distances, it is called precision seeder (SANTOS et al., 2008; KAMIMURA et al., 2009).

The seeder-fertilizer machines can be equipped with fertilizer metering mechanisms of types: horizontal hard drilled, inclined perforated disc and pneumatic disc. The disk that operates in the horizontal position is the most used in Brazilian seeders, showing poor performance, in terms of uniformity of sowing, when it is done at speeds greater than 6.0 km h-1. The pneumatic disc can work with positive or negative pressure. The negative pressurization, known as vacuum, is produced by the turbine itself of the seeder, which is driven by PTO or hydraulic system of the tractor. This mechanism has as main advantage the distribution uniformity (PINEIRO NETO et al., 2008; SILVA et al., 2011).

Corn seeds are classified based on the grain size (sieve), selling about 40 different types. In the system of horizontal perforated disc, there are approximately 90 options, with 30 orifices sizes in the disc and three depths of rings (JASPER et al., 2009). The pneumatic seeders have about ten options, varying the thickness, number and size of orifices (PORTELLA, 2001).

The quality of seeds distribution is the focus of several innovations. In 2006, the Financiadora de Estudos e Projetos (FINEP - Financier of Studies and Projects) awarded the technological development of horizontal perforated disc with gradient level at the back of the disc hole (disc with ramp®). This project would be able to reduce by 50% the flaws in the seeding process, such as duplication or absence of seeds (FINEP, 2006).

In bench trials, JASPER et al. (2006) did not identify the existence of selection of different sizes of corn seeds during the process of seeding, as well as the possible consequences of the longitudinal distribution along the sowing process.

Working with the pneumatic and horizontal perforated disc metering mechanisms at corn sowing, GARCIA et al. (2006) concluded that there is an increase in the percentage of faulty and multiple spacing and a decrease of acceptable spacing when rising the speed of the sowing; however, the productivity was only affected when the plant population with cobs was reduced by increasing speed.

The seeder with pneumatic system showed better performance than the mechanical system in the dosage and distribution of soybean seeds, with greater accuracy in the range of acceptable spacing (TOURINO et al., 2007). JASPER et al. (2011) concluded that there were no significant differences in the productivity of the crop sown with horizontal perforated and pneumatic disc systems.

When studying the influence of the speed of corn sowing in the quality of distribution, MAHL et al. (2008) concluded that there was no influence on the initial and final stands of plants, but there was a significant interference in the regularity of longitudinal distribution of seeds; being obtained at the slowest speed (4.4 km h-1) the highest percentage of normal spacing. The pneumatic injector had a better performance than the horizontal perforated disc, the longitudinal distribution of plants. Under the aspect of productivity, it was indifferent the recommendation of use of pneumatic seed metering mechanisms and horizontal perforated disc.

The objective of this study was to determine whether the seed metering mechanisms affect the quality of sowing and corn yield components in no-tillage system.

MATERIAL AND METHODS

The experiment was conducted in a rural property located in the city of Pirai do Sul - PR, Brazil, with a cultivated area of 1,665 ha, of which 855 ha were cultivated with maize in 2008/2009 harvest. The property is located at coordinates 25°16" south latitude and 50°16" west longitude, Cfb climate, on a Typic Eutrophic (EMBRAPA, 2006) in no-till system of more than 25 years, with varying straw between 4.0 and 8.0 t ha-1. The previous crop was oat (Avena strigosa). The fertilizer was 300 kg ha-1 of 14-34-00 formula, following the recommendations of the Agronomist responsible for the area. The rainfall covering the period when the maize crop was in the field is detailed in Figure 1, with averages of data collected by rain gauges on properties where the experiment was conducted.

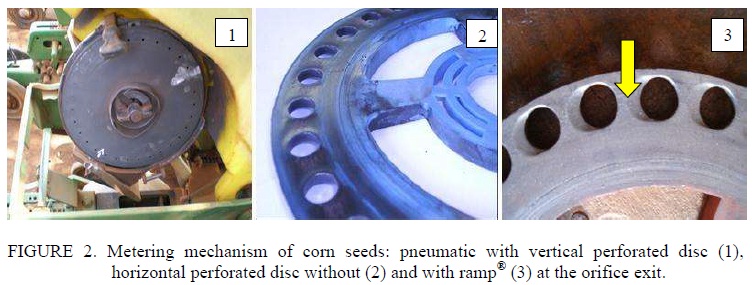

It was compared the performance of the metering mechanism of corn seed (Zea mays) in direct seeding. The experiment was conducted in a randomized block design (RBD), with three treatments and nine repetitions for four corn hybrids. The treatments of seed distributors were the pneumatic with vertical perforated disc, horizontal perforated disc with and without ramp® (Figure 2).

Four corn hybrids were seeded in 200 ha, 50 ha each, with hybrid and seeds of different sieves, in order to measure the performance of metering mechanisms in specific work situations. It was distributed the hybrids 32R48® (R3G rounded sieve and lot 16,137), 30R50® (C2H flat sieve and lot 68,721), 30F53® (C2M flat sieve and lot 28,010), and 30P34® (R3G rounded sieve and lot 16,230).

Seed treatment was made with 330 mL ha-1 of Cropstar® (150 g L-1 of imidacloprid, and 450 g L-1 of thiodicarb), 190 mL ha-1 of Broadacre Mn (50% Mn) and 190 mL ha-1 of Broadacre ZnCu (63% Zn and 16% Cu). After the treatment of the seeds, it was added 4.0 grams of graphite per 1.0 kg of seed to enhance flow ability. It was followed the recommendations of the Agronomist responsible for the area; and there were 72,000 seeds ha-1 for hybrid 30P34® and 78,000 seeds ha-1 for the other hybrids.

The choice of horizontal perforated disc and ring for each hybrid was due to the recommendation printed on the package, as follows: disc with oblong holes of 12.5 x 8.5 mm, and ring with recess of 2.0 mm for hybrid 32R48®; disc with round holes of 12.5 mm and no recess ring (0.0 mm) for hybrid 30R50®; round disc with holes of 12.0 mm and no recess ring for hybrid 30F53®; and disc with oblong holes of 12.5 x 8.5 mm, and ring with recess of 2.0mm for 30P34® hybrid.

The pneumatic seeder-fertilizer used was the SLC 913®, equipped with six units of sowing, spaced at 0.80 m, with discs of 30 orifices, pressure of 0.8 MPa for all hybrids, smooth cutting disc, and 0.43 m diameter, furrow opening mechanism of the fertilizer and seeds with offset double disc of 0.41 m diameter. The furrow closing occurred by double-angled wheels in "V" of 0.30 m diameter. The tractor used was the John Deere® 7505 (140 hp).

The seeder-fertilizer which distributed the seeds with the horizontal perforated disc without ramp® was the PP Solo Directa 5000®, equipped with seven units of seeding spaced at 0.80 m, smooth cutting disc of 0.43 m diameter, furrow opening mechanism of fertilizer and seeds with offset double disc of 0.3 6m diameter. The furrow closing occurred by double-angled wheels in "V" of 0.30 m diameter. The tractor used was the Case® MXM 150 (150 hp).

The fertilizer-seeder with horizontal perforated disc with ramp® was the SSM 27®, equipped with six units of sowing spaced at 0.80 m, smooth cutting disc of 0.36 m diameter, furrow opening mechanism of the fertilizer and seeds with offset double disc of 0.33 m diameter. The furrow closing occurred by double-angled wheels in "V" of 0.30 m diameter. The tractor used was the John Deere® 7500 (140 hp).

Sowing was always performed with speed between five and 6 km h-1, previously determined by the relation between space and gears time and acceleration of work of each tractor. All seeders were regulated so that the seed was distributed to 0.05 m deep and the fertilizer to 0.05 m below and beside the seeds. All corn seeds were above 95% germination and below 1% impurity. The seeding was done with friable soil, in September, 2008. Base and cover fertilization, weed, pest and disease control followed the agronomic recommendations. The crop was harvested in March.

The seeder-fertilizers worked side by side. The assessment area occurred in 40 m2 (3.2 x 12.5 m) and were distributed in blocks leased in early (three blocks), middle (three blocks) and late sowing (three blocks) of four corn hybrids evaluated. The refueling took place over remaining seeds in the dispenser mechanism, to measure possible segregation of seed size which could affect the quality of the longitudinal distribution along the sown area.

The assessment of longitudinal distribution occurred by the analysis of spacing between plants, 25 days after emergence (DAE), based on the recommendations of the BRAZILIAN ASSOCIATION OF TECHNICAL STANDARDS (1989), which considers as acceptable all plant spacing 0.5 and 1.5 times the average spacing (AS) expected. The values obtained out of this limit were considered as faulty spacing (above 1.5 times AS) or multiple (below 0.5 times AS). It was ignored the outside planting rows, considered as margin, collecting data on the central lines.

It was measured the final population by counting the number of plants with cob in the 40 m2 plot. Harvesting, threshing, counting grains per cob and thousand grain weight were performed manually. The determination of thousand grain weight and yield occurred with 1.0% of impurities and moisture corrected to 14.5% wb (CLASPAR, 2011). The moisture was observed with the use of measured moisture (G800 Gehaka®). The weight of a thousand grains was defined by means of a Diamond® digital scale (0.1 to 500 g). The yield of the plot of 40 m2 was measured using Micheletti® Digital Electronic Industrial Scales of 100 kg.

It was used the Hartley test for checking the homogeneity of variances. The variables measured were subjected to the F test for analysis of variance and comparison of means by Duncan test, with a confidence level greater than 95% probability. It was used the software SASM - Agri®.

RESULTS AND DISCUSSION

Hartley's test indicated the homogeneity of variances for all variables. So there was no need for transformation of the means for application of F test. There were no significant differences for blocks in all variables (Table 1), indicating the homogeneity of experimental conditions and no size selection of seeds which could affect the quality of longitudinal distribution. The results corroborate with JASPER et al. (2006), who did not identify the existence of seed selection and the possible consequences on the longitudinal distribution along the seeding process.

The number of seedlings with 25 days after emergence and longitudinal distribution parameters were not significantly affected by the metering mechanisms of corn seed in four hybrids and three sieves, on an area of 200 ha. As the F test did not accuse significant differences between the variances of the treatments, there was no need for using the Duncan test.

The initial population showed minimal losses for seeds distributed, denoting seed quality, adjustment of the machines and adequate rainfall (Figure 1), thereby addressing the factors listed by PORTELLA (2001), SANTOS et al. (2008), JASPER et al. (2009) and SILVA et al. (2011).

The faulty spacing were an average of about 6.0%, multiples in 4.0% and acceptable with 90%, not significantly different when distributed by vertical discs in pneumatic system, mechanical system with horizontal perforated discs with and without ramp®. The results differ from the statements of FINEP (2006) on the ability of horizontal perforated discs with ramp® to reduce by 50% the flaws in the process, as the absence or duplication of seeds in the longitudinal distribution of seeds. Thus, the depression in the orifice exit of the horizontal perforated disc did not significantly affect the longitudinal distribution.

The conclusions of TOURINO et al. (2007), which demonstrate the superiority of pneumatic system compared to the mechanic at soybean sowing, were not substantiated by the results obtained by corn sowing. In the data analysis of longitudinal distribution of plants, it was not found the best performance of the pneumatic injector in relation to horizontal perforated disc, mentioned by MAHL et al. (2008).

The analysis of variance of yield components for the F test, with a confidence level exceeding 95%, did not identify significant differences for the blocks (Table 2). Despite the size of the area used in the experiment, the homogeneity of experimental conditions denoted in the analyses of the installation of the culture was maintained until harvest. This shows that under the experimental conditions, the seed metering mechanisms maintained the effectiveness of operation, reflecting on yield components. This confirms the statements of SANTOS et al. (2008).

The number of cobs per hectare, grains per cob, thousand grain weight and yield of four corn hybrids were not affected significantly by seed distributors of pneumatic with vertical perforated disc, mechanical system with horizontal perforated disc with and without ramp. As the F test was not significant, there was no need to apply the Duncan test.

The results did not corroborate the affirmations of TOURINO et al. (2007) and SILVA et al. (2011) on the advantages of pneumatic seed distribution in relation to the mechanical system. It was not identified in the statement of FINEP (2006) about the superiority of the horizontal perforated disc with gradient level at the back of the disc hole (disc with ramp®) when compared to conventional disc.

The collected data corroborates with the statements of GARCIA et al. (2006), MAHL et al. (2008) and JASPER et al. (2011) on the indifference of recommendation in the use of pneumatic and horizontal perforated disc seed metering mechanisms on the yield of corn crop.

CONCLUSION

The sowing of corn with pneumatic, horizontal perforated disc with or without ramp® seed metering mechanisms did not significantly differ in the quality of longitudinal distribution of seeds and yield components.

Recebido pelo Conselho Editorial em: 9-1-2012

Aprovado pelo Conselho Editorial em: 13-6-2012

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. Semeadora de precisão: ensaio de laboratório/método de ensaio. Projeto de norma 12:02.06-004. Rio de Janeiro, 1989. 21 p.

- CLASPAR. Produtos padronizados: milho, 2011. Disponível em: http://www.claspar.pr.gov.br/arquivos/File/pdf/milho11_96.pdf Acesso em: 29 abr. 2011.

- CONAB. Acompanhamento de safra brasileira: grãos, décimo primeiro levantamento, agosto 2011. Brasília: CONAB, 2011. 41p.

- EMBRAPA. Sistema brasileiro de classificação de solos 2.ed. Rio de Janeiro: EMBRAPA Solos, 2006. 306 p.

- FINEP. Prêmio FINEP de inovação tecnológica 2006 Brasília: FINEP, 2006. 169 p.

- GARCIA, L.C.; JASPER, R.; JASPER, M.; FORNARI, A.J.; BLUM, J. Influência da velocidade de deslocamento na semeadura do milho. Engenharia Agrícola, Jaboticabal, v.26, n.2, p. 520-527, 2006.

- JASPER R.; JASPER, M.; ASSUMPÇÃO, P.S.M.; ROCIL, J.; GARCIA L. C. Velocidade de semeadura da soja. Engenharia Agrícola, Jaboticabal, v.31, n.1, p.102-110, 2011.

- JASPER R.; JASPER, M.; GARCIA L. C. Seleção de sementes de milho durante a simulação da semeadura com disco perfurado horizontal. Engenharia Agrícola, Jaboticabal, v.26, n.2, p. 434-441, 2006.

- JASPER R.; JUSTINO, A.; MORGADO C.B.; DYCK, R.; GARCIA L. C. Comparação de bancadas simuladoras do processo de semeadura em milho. Engenharia Agrícola, Jaboticabal, v.29, n.4, p. 623-629, 2009.

- KAMIMURAI, K.M.; LEVIEN, R.; TREIN, C.R.; DEBIASI, H.; CONTE, O. Parâmetros solo-máquina em função de doses de resíduos vegetais e profundidades de deposição de adubo em semeadura direta. Engenharia Agrícola, Jaboticabal, v.29, n.3, p. 431-439, 2009.

- MAHL, D.; FURLANI, C.E.A.; GAMERO, C.A. Efficiency of pneumatic and horizontal perforated disk meter mechanism in corn no-tillage seeders in soil with different mobilization reports. Engenharia Agrícola, Jaboticabal, v.28, n.3, p. 535-542, 2008.

- PINHEIRO NETO, R.; BRACCINI, A.L.; SCAPIM, C.A.; BORTOLOTTO, V.C.; PINHEIRO, A.C. Desempenho de mecanismos dosadores de sementes em diferentes velocidades e condições de cobertura do solo. Acta Scientiarum Agronomy Maringá, v. 30, n.5, p. 611-617, 2008.

- PORTELLA, J. A. Semeadoras para plantio direto Viçosa: Aprenda Fácil Editora, 2001. 252 p.

- SANGOI, L.; SCHMITT, A.; SALDANHA, A.; FIORENTIN, C.F.; PLETSCH, A.J.; VIERIA, J.; GATTELLI, M.A. Rendimento de grãos de híbridos de milho em duas densidades de plantas com e sem a retirada dos perfilhos. Ciência Rural, Santa Maria, v.39, n.2, p.325-331, 2009.

- SANTOS, A.P.; VOLPATO, C.E.S.; TOURINO, M.C.C. Desempenho de três semeadoras-adubadoras de plantio direto para a cultura do milho. Ciência e Agrotecnologia, Lavras, v.32, n.2, p.540-546, 2008.

- SILVA, G.J.; GUIMARÃES, M.C.; FONSECA J.R. Preparo do Solo e Semeadura. In: Embrapa Arroz e Feijão. Cultivo do Arroz de Terras Altas no Estado de Mato Grosso Disponível em: http://sistemasdeproducao.cnptia.embrapa.br/FontesHTML/Arroz/ArrozTerrasAltasMatoGrosso/index.htm Acesso em: 25 ago. 2011.

- TOURINO, M.C.C.; REZENDE, P.M.; ALMEIDA, L.G.P.; SILVA, L.A. Comparativo na uniformidade / distribuição de sementes em função do tipo de semeadoras. Revista Brasileira de Agrociência, Pelotas, v.13, n.3, p.383-392, 2007.

Publication Dates

-

Publication in this collection

12 Nov 2012 -

Date of issue

Oct 2012

History

-

Received

09 Jan 2012 -

Accepted

13 June 2012