Abstract

To investigate the simultaneous influence of different non-nutritional factors in production and physical-chemical characteristics of chitosan obtained by Syncephalastrum racemosum we used individually agroindustrial wastes as the only nutritional sources for fungus growth. The growth conditions were evaluated according to Factorial Design, 24 with three central points in order to determine the mainly factors for maximum production of microbiological chitosan in submerged culture. Syncephalastrum racemosum grown in corn steep liquor and yield up to 7.8 g chitosan/kg of substrate in the best condition by factorial design. The microbiological chitosan obtained has deacetilation degree 88.14%, crystallinity rate of 55.96%, mass decomposition process at 304.43 ºC, and low molecular weight. To fast production we performed a kinetic study and confirmed that at 36 h the chitosan production is higher and the physical-chemical characteristics were maintained. This research describes, for the first time, the factorial study of chitosan production by Syncephalastrum racemosum in agroindustrial wastes and its economic potential for commercialization.

Key words

cassava wastewater; whey; corn steep liquor; microbiological chitosan; Syncephalastrum racemosum

INTRODUCTION

Nowadays, the natural synthesis of biopolymers by microorganisms has been related to selected strain, to lifecycle phase of the microorganism, to carbon and nitrogen sources of the culture medium, to pH and to incubation temperature. All these factors can cause an increase and improvement of the physical-chemical properties of biopolymers (Amorim et al. 2006AMORIM RSV, LENDIGHAM WM, KENNEDY JF & CAMPOS-TAKAKI GM. 2006. Chitosan from Syncephalastrum racemosum using sugar cane substrates as inexpensive carbon sources. Food Biotechnol 20: 43-53., Fasciotti 2017FASCIOTTI M. 2017. Perspectives for the use of biotechnology in green chemistry applied to biopolymers, fuels and organic synthesis: from concepts to acritical point of view. Sust Chem Pharm 6: 82-89., Mahopatra et al. 2017MAHOPATRA S, MAITY S, DASH HR, DAS S, PATTNAIK S, RATH CC & SAMANTARAY D. 2017. Bacillus and biopolymer: Prospects and challenges. Biochem Biophys Rep 12: 206-213., Silva et al. 2010SILVA AC, GUIMARÃES PMR, TEIXEIRA JA & DOMINGUES L. 2010. Fermentation of deproteinized cheese whey powder solutions to ethanol by engineered Saccharomyces cerevisiae: effect of supplementation with corn steep liquor and repeated-batch operation with biomass recycling by flocculation. J Ind Microbiol Biotechnol 37: 973-982., Wang et al. 2008WANG W, DUA Y, QIU Y, WANG X, HU Y, YANG J, CAI J & KENNEDY JF. 2008. A new green technology for direct production of low molecular weight chitosan. Carbohydr Polym 74: 127-132). Among the researched biopolymers, there are the chitosan (CS) a biopolymer constituted of β-(1-4)-2-amino-2-deoxy-D-glucopyranose glycosidic residues, which is naturally found as constituent of the cell wall of fungi, especially the species belonging to the Zygomycetes class (Campos-Takaki 2005CAMPOS-TAKAKI GM. 2005. The fungal versatility on the copolymers chitin and chitosan productionp. In: Dutta PK (Ed), Chitin and Chitosan Opportunities and Challenges. SSM International Publication, Midnapore, India, p. 69-94., Muzzarelli & Peter 1997MUZZARELLI RAA & PETER MG. 1997. Chitin handbook. AtecEdizioni, Grottammare Oliveira CEV, Magnani M, Sales CV, Pontes ALS, Campos-Takaki GM, Stamford TCM & Souza EL (Eds), Effects of post-harvest treatment using chitosan from Mucor circinelloides on fungal pathogenicity and quality of table grapes during storage. Food Microbiol 44: 211-219.), or chemical obtained by deacetylation of chitin residues (Tajik et al. 2008TAJIK H, MORADI M, ROHANI SMR, ERFANI AM & JALALI FSS. 2008. Preparation of chitosan from brine shrimp (Artemia urmiana) cyst shells and effects of different chemical processing sequences on the physicochemical and functional properties of the product. Molecules 13: 1263-1274.). Among the Zygomycetes, especially, the Syncephalastrum racemosum specie has presented a great potential for chitosan production when it is grown in simple culture medium and of low cost (Amorim et al. 2006AMORIM RSV, LENDIGHAM WM, KENNEDY JF & CAMPOS-TAKAKI GM. 2006. Chitosan from Syncephalastrum racemosum using sugar cane substrates as inexpensive carbon sources. Food Biotechnol 20: 43-53.).

At present, chitosan commercialized in large scale is originated from the chemical alkaline hydrolysis of shrimp chitin, with cost of, approximately, U$10.00/g (Sigma Chemical Co., USA). In the microbiological chitosan production, there is a very high cost due to high prices of synthetic culture media and low yield in the production. However, for its competitive commercialization, agroindustrial wastewaters have been used as alternative media for fungi grown in submerged fermentation. These agroindustrial wastewaters are readily available and its low cost to use, resulting in 38 – 73% saving of the total cost of the bioproduct production (Amorim et al. 2006AMORIM RSV, LENDIGHAM WM, KENNEDY JF & CAMPOS-TAKAKI GM. 2006. Chitosan from Syncephalastrum racemosum using sugar cane substrates as inexpensive carbon sources. Food Biotechnol 20: 43-53., Hamano & Kilikian 2006, Schmidell 2001SCHMIDELL W. 2001. Microrganismos e meios de cultura para utilização industrial. In: Schmidell W, Lima UA, Aquarone E & Borzani W (Ed), Biotecnologia Industrial Vol. 2. Edgard Blücher, São Paulo, p. 5-18.).

Due to the great interest in production of chitosan (Batista et al. 2013BATISTA ACL, FREITAS SILVA MC, BATISTA JB, NASCIMENTO AE & CAMPOS-TAKAKI GM. 2013. Eco-Friendly Chitosan Production by Syncephalastrum racemosum and Application to the Removal of Acid Orange 7 (AO7) from Wastewaters. Molecules (Basel. Online) 18: 7646-7660., Dos Santos et al. 2013DOS SANTOS E, FREITAS SILVA MC, SOUZA PM, SILVA AC, PAIVA SC, ALBUQUERQUE CDC, NASCIMENTO AE, OKADA K & CAMPOS-TAKAKI GM. 2013. Enhancement of Cunninghamella elegans UCP/WFCC 0542 Biomass and Chitosan with Amino Acid Supply. Molecule (Basel.Online) 18: 10095-10107., Zhang et al. 2014ZHANG H, YANG S, FANG J, DENG Y, WANG D & ZHAO Y. 2014. Optimization of the fermentation conditions of Rhizopus japonicus M193 for the production of chitin deacetylase and chitosan. Carbohydr Polym 101: 57-67.) and biotechnological applications (Baldrick 2010BALDRICK P. 2010. The safety of chitosan as a pharmaceutical excipient. Regul Toxicol Pharmacol 56: 290-299., El-Sawy et al. 2010EL-SAWY NM, EL-REHIM, HAA, ELBARBARY AM & HEGAZY E-SA. 2010. Radiation-induced degradation of chitosan for possible use as a growth promoter in agricultural purposes. Carbohydr Polym 79: 555-562., Ibrahim et al. 2014IBRAHIM M, TAO Z, HUSSAIN A, CHUNLAN Y, ILYAS M, WAHEED A, YUN F, LI B & XIE G-L. 2014. Deciphering the role of Burkholderia cenocepacia membrane proteins in antimicrobial properties of chitosan. Arch Microbiol 196: 9-16.) by scientific community, this research aimed at investigating different types of organic waste, temperature, pH and inoculum size as parameters which could influence microbiological chitosan production and its physical-chemical characterization.

MATERIALS AND METHODS

Microorganism and culture medium

Syncephalastrum racemosum (UCP/WFCC 0148), obtained through stools of herbivore (Northeast – Brazil), was isolated by a soil plate method of potato-dextrose agar (PDA), with incubation at 37 °C for 10 days (Matsuzawa et al. 2014MATSUZAWA T, CAMPOS-TAKAKI GM, YAGUCHI T, OKADA K, GONOI T & HORIE Y. 2014.Two new species of Aspergillus section Fumigati isolated from caatinga soil in the State of Pernambuco, Brazil. Mycoscience 55: 79-88.). After monosporic culture isolation and identification, S. racemosum was grown in PDA (Potato Dextrose Agar, Oxoid) solid medium pH 5.5 at 28 °C for 120 h (5 days). Fungal spores were suspended in sterilized water and maintained at 4 °C to be used during the whole experiment. Inoculum concentration of culture medium was in accordance with factorial design, with three central points (Table I). Whey (SM) agroindustrial wastewaters, cassava wastewater (CW) and corn steep liquor (CSL) were kindly provided by local industries. S. racemosum was grown in culture medium containing only one of the agroindustrial wastewaters as the only carbon and nitrogen source according to Table I.

24 full factorial design, with three central points. Coded (cd) and uncoded (ucd) values to assess the main effects of independent variables on chitosan production.

For the formulation of culture media, concentrated agroindustrial wastewaters were diluted in distilled water (v/v) as described in Table I. Fermentations were carried out in bottles of 1,000 mL, containing 400 mL of medium at 150 rpm and 120 h. Chitosan was extracted according Hu et al. (1999)HU K-J, YEUNG KW, HO KP & HU J-L. 1999. Rapid extraction of high-quality chitosan from mycelia of Absidia glauca. J Food Biochem 23: 187-196.. At first stage, the powdered dry biomass was added to a solution of 1 M NaOH at ration 1:40 (w/v) and homogenized. The deproteinization occurred at 121°C for 15 min at 1atm. Alkali-insoluble materials resulting were filtered and neutralized. At second stage, this alkali- insoluble material was freeze-dried and powdered. 2% acetic acid solution was added to alkali-insoluble materials at ration 1:100 (w/v) and homogenized. The acid extraction occurred at 121 °C for 15 min. Then, the supernatant was decanted into a beaker and the pH of the supernatant was adjusted to 10.0 to precipitate the chitosan.

Physical-chemical characterization of chitosan

For analyzing percentage of total carbohydrates and nitrogen, the methodologies described by Cunniff (1995)CUNNIFF P. 1995. Official Methods of Analysis of the Association of Official Analytical Chemists (method 958.06). Arlington, VA, p. 21. and Kjeldahl´s method Labconcq (2005)LABCONCQ. 2005. To Kjeldahl Nitrogen determination methods and apparatus. ExpotechUSA. Houston, Texas, USA. http://www.expotechusa.com/catalogs/labconco/pdf/KJELDAHLguide.PDF. Acessed 06 July 2008.

http://www.expotechusa.com/catalogs/labc...

were used, respectively.

Deacetylation degree (DD) of chitosan was determined through infrared method and calculated by equation 1 (Guibal 2004GUIBAL E. 2004. Interactions of metal ions with chitosan-based sorbents: a review. Sep Purif Technol 38: 43-74.). Crystallinity (X-ray diffractometer, Ultima model, Rigaku Corporation, Japan) rate was calculated according to equation 2 (Focher et al. 1990FOCHER B, BELTRAME PL, NAGGI A & TORRI G. 1990. Alkaline N-deacetylation of chitin enhanced by flash treatments: Reaction kinetics and structure modifications. Carbohydr Polym 12: 405-418.).

Where I(θc) is the relative intensity of crystalline regions (2θ = 20°) and I(θa) corresponds to amorphous regions (2θ = 12°) for chitosan.

Dynamic thermogravimetric analyses (TGA) were determined in one thermobalance (TGA-50 model, Shimadzu Corporation, Japan) using an aluminum crucible. Experiments were accomplished based on 10, 20 and 40 °C/min at 900 °C/min ratios in synthetic air and nitrogen with flow of 20 and 50 mL/min, respectively. The sample mass was of 5.2 ± 0.1 mg. The TGA curves were analyzed through TASYS (Shimadzu) program.

Differential calorimeter curves were obtained using Differential Scanning Calorimeter (DSC) (DSC-50 model, Shimadzu Corporation, Japan) at a rate from 10 °C/min to 900 °C/min, in nitrogen atmosphere (50 mL/min). Samples were packed in an aluminum crucible, with a mass of 2.00 mg (± 0.05). DSC curves were analyzed through TASYS (Shimadzu) program.

Molecular weight of chitosan was estimated by viscosimetry (Terbojevich & Cosani 1997TERBOJEVICH M & COSANI A. 1997. Molecular weight determination of chitin and chitosan. In: Muzzarelli RAA & Peter MG (Eds), Chitin Handbook. AtecEdizioni, Grottammare, p. 87-101.). Measurement was done from the average of chitosan solutions (0.3 – 0.6 mg/mL) in 1% acetic acid solution, always in triplicate. For this procedure, it was used viscosimeterUbbelohde (B8060C model, Cannon Instrument Company, EUA).

Factorial Design and statistical analysis

In order to verify the effect of independent variables (concentration of agroindustrial wastewaters, pH, temperature and size of inoculum) in chitosan production, factorial design 24, with three central points, was proposed and fulfilled in duplicate (Table I). All the analyses of data and graphs were done by means of the Statistica 7.0 software package (STATISTICA, version 7 2004STATISTICA. 2004. Version 7, StatSoft, Inc. http://www.statsoft.com.

http://www.statsoft.com...

). The statistical significance of the results was tested at p <0.05 level.

RESULTS

Agroindustrials wastes influence on biomass production

Results showed that, among the agroindustrials wastes used in this study, whey and cassava wastewater induced low biomass production, not being higher than 15 mg and 5 mg of dry biomass, respectively, after 120h by S. racemosum. This occurred independently of conditions tested by factorial design. Because the low biomass production the extraction of microbiological chitosan was not profitable. Hence, these wastewaters were left out temporarily. The aim of this article is the use of only wastewater, differing from others in the literature, which complement the wastewater with some amino acids, carbohydrate or other expensive supplements to compose the culture media (Ghosh & Ray 2011GHOSH B & RAY RR. 2011. Extra-cellular Isoamylase Production by Rhizopus oryzae in Solid-State Fermentation of Agro Wastes. Braz Arch BiolTechnol 54: 867-876., Dos Santos et al. 2013DOS SANTOS E, FREITAS SILVA MC, SOUZA PM, SILVA AC, PAIVA SC, ALBUQUERQUE CDC, NASCIMENTO AE, OKADA K & CAMPOS-TAKAKI GM. 2013. Enhancement of Cunninghamella elegans UCP/WFCC 0542 Biomass and Chitosan with Amino Acid Supply. Molecule (Basel.Online) 18: 10095-10107., Tasar et al. 2016TASAR OC, ERDAL S & TASKIN M. 2016. Chitosan production by psychrotolerant Rhizopus oryzae in non-sterile open fermentation conditions. International Journal of Biological Macromolecules 89: 428-433., Abdel-Gawad et al. 2017ABDEL-GAWAD KM, HINEY AF, FAWZY MA & GOMAA M. 2017. Technology optimization of chitosan production from Aspergillus niger biomass and its functional activities. Food Hydrocolloids 63: 593-601.).

In our research, the only wastewater which favored biomass production by S. racemosum was corn steep liquor (CSL). It was used as the only carbon and nitrogen source in culture medium. By means of the centesimal composition evaluation of total carbon source (17.57%) and total nitrogen (13.03%) in concentrated CSL used in formulation of culture media, it is possible to suggest that this fact may have influenced the fungi growth. Divergence among the CSL nutritional values can occur due to corn origin.

Effects evaluation of independent variables regarding chitosan production

The complete factorial design used in the present research showed that the best condition for chitosan production occurred when the nutritional source in culture medium was only 2% (v/v) of concentrated CSL, with initial pH 8.0, temperature 25 °C and inoculum size 102 sporangioles/mL (Table II). For this condition, chitosan yield was of 7.8 g/kg of substrate and the independent variables were considered important for costs reduction and standardization of microbiological chitosan production when compared with other media of standard or alternative culture for chitosan production by fungi (Table III).

Complete factorial design to analysis the main effects and interactions among independent variables (concentration of corn steep liquor – A(x1), initial pH – B(x2), incubation temperature – C(x3), and inoculum size – D(x4)) regarding the influence on dependent variables (final pH of culture medium – R1, and chitosan yield – R2).

Nutritional composition cost of one liter of culture medium for fungi. Expenses with distilled water are not included.

Analysis of variance (ANOVA) of the results indicated meaningful effect in the interference of independent variables in chitosan production, especially for the interactions: pH * temperature * inoculum size. The low experimental error when compared to absence of adjustment suggests the safety of the technique of microbiological chitosan extraction and its reprodutibility. The results were verified by the R2 determination coefficient which explains 92.12% of the obtained response variability.

In order to evaluate the interference of the temperature limited variation in the production and maintenance of physical-chemical characteristics of chitosan, the selected condition by the complete factorial design was incubated at 28 °C (local average environmental temperature) for 120h. The procedure occurred in duplicate. The results showed non-interference of temperature around 25 – 28 °C (data not shown).

Growth and production kinetics of chitosan

After selection the best growing condition and chitosan production by S. racemosum in culture medium containing only CSL as nutritional source (2% (v/v) concentrated CSL, pH 8.0, 28 °C, inoculum size of 100 sporangioles/mL, studies of kinetics for determining the least incubation period aiming at cost reduction of chitosan production, without loss of productivity and quality, were accomplished.

In Table IV, Tukey test demonstrates that from 36h up to 120h at 28 °C incubation, chitosan yield presented no meaningful variation of values. The apparent increase of chitosan yield at 120h can be explained by the variation found between the quadruplicates, however the ANOVA test and Tukey’s HSD test demonstrated that this difference is in the normal range and it was not significant. Fermentations were carried out in bottles of 1,000 mL, containing 400 mL of medium at 150 rpm.

Growth curve for dry biomass of Syncephalastrum racemosum and chitosan production in selected condition by factorial design.

Analyzing chitosan production for hours, it was expected that the quantity obtained would be higher at the end of 120 h, assuming that the production at 24 h was 26 mg / g, then the production at 120h should be 130 mg / g. Factors intrinsic to the submerged system are suggested as interferers and favored a peak production at 36 hours. The result favors time saving and cost reduction embedded in culture submerged system using shakers. Chitosan produced was analysed (deacetilation degree, cristalinity, thermogravimetry and molecular weight). Statistics differences were not observed.

Physical-chemical characteristics of chitosan

For assuring that the obtained biopolymer is really chitosan, there was the characterization and comparison of the acquired product with the commercialized chitosan by Sigma (Sigma Chemical Co., EUA, 2011).

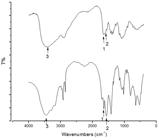

In Figure 1, the spectrophotometric analysis by Fourier Transformed Infrared spectroscopy (FT-IR) of commercial and microbiological chitosans allowed the characterization of the degree of deacetylation, which determines the quantity of free amino groups in the molecule. FT-IR estimated that microbiological chitosan presented 88.14% degree of deacetylation and commercial chitosan 78.52% degree of deacetylation. To characterize the FT-IR analysis by literature some peaks were described: peak 1 (~ 1,650 cm-1) corresponding to NHCOCH3 group present in chitosan acetylated residues; peak 2 (~ 1,590 cm-1), corresponding to NH2 groups present in deacetylated residues; and peak 3 (3,440 cm-1), corresponding to OH strained vibrations of molecule (Wang et al. 2008WANG W, DUA Y, QIU Y, WANG X, HU Y, YANG J, CAI J & KENNEDY JF. 2008. A new green technology for direct production of low molecular weight chitosan. Carbohydr Polym 74: 127-132).

Comparative FTIR spectrum between microbiological chitosan (top line; deacetylation degree of 88.14%) and commercial chitosan (bottom line; deacetylation degree of 78.54%).

The presence of characteristic peaks in both chitosans stimulates production of microbiological chitosan with commercial potential by alternative nutritional sources associated with others variables tested in this work.

In Figure 2, the characteristics peaks for chitosan 2θ = ~ 10.12° and 2θ = ~ 20.10°, can be observed in microbiological chitosan (Kumirska et al. KUMIRSKA J, CZERWICKA M, KACZYŃSKI Z, BYCHOWSKA A, BRZOZOWSKI K, THÖMING J & STEPNOWSKI P (2010). Application of spectroscopic methods for structural analysis of chitin and chitosan. Marine Drugs 8: 1567-16362010), obtaining a crystallinity rate of 55.96%. Comparatively, commercial chitosan was presented as amorphous due to the absence of peaks in 2θ = 10° or 20°.

Comparative analysis among X-rays diffraction spectra of commercial chitosan (amorphous) and microbiological chitosan (ICR = 55.96%).

Thermal stability of chitosan was investigated by means of thermogravimetrical analysis (TGA), which can monitor mass loss of a sample in function to temperature and time increase. Water loss through microbiological chitosan occurred in a continuous way, being mixed with mass degradation phases up to 240 °C, when it was necessary a larger absorption for the rupture bonds of intermolecular hydrogen and, consequently, water volatilization in the first degradation phase. Results corroborate the semi-crystalline characterization of microbiological chitosan and the amorphous condition of commercial chitosan (Table V).

Thermal parameters of TGA and DSC analyses for evaluating microbiological and commercial chitosan.

The analysis of DSC curves for microbiological chitosan in N2 atmosphere, at temperatures between 2 – 50 °C, presents two peaks endothermic: the first , corresponding to the dehydration process at 56.77 °C, with 62.11 J/g power absorption; the second corresponding to the decomposition process at 140,55 °C, with power release of 19,01 J/g. The two processes are consistent in relation to the phases of mass loss observed in the TG curve for the microbiological chitosan samples.

The study of viscosimetric molecular weight demonstrated that chitosan obtained by microbiological via presents low molecular weight when compared to commercial chitosan (average molecular weight).

DISCUSSION

For the studies of critical composition of culture medium, literature describes low production of fungal biomass and bioproduct when fungus is grown in the presence of lactose as the only carbon source as well as in the presence of inhibiting factors of chitin deacetylase, as Ca2+ and carboxylic acids, present in whey (Ghosh & Ray 2011GHOSH B & RAY RR. 2011. Extra-cellular Isoamylase Production by Rhizopus oryzae in Solid-State Fermentation of Agro Wastes. Braz Arch BiolTechnol 54: 867-876., Hamano & Kilikian 2006), except for cellulase production by fungi, when lactose enhances production of several proteins with cellulase activity (Hu et al. 1999HU K-J, YEUNG KW, HO KP & HU J-L. 1999. Rapid extraction of high-quality chitosan from mycelia of Absidia glauca. J Food Biochem 23: 187-196.).

Result of low production of fungal biomass in cassava wastewater is suggested by the presence of cianoglycosides, which can generate from 0.2 – 100 mg of HCN by 100 g of fresh manioc and induce cell rupture (Bradbury et al. 1991BRADBURY J-H, EGAN SV & LYNCH MJ. 1991. Analysis of cyanide in cassava using acid hydrolysis of cyanogenicglucosides. J Sci Food Agric 55: 277-290.). Moura et al. (2018)MOURA AS, MEDEIROS RV, OLIVEIRA JES, FRANCA RF, LIRA AD, MARTINS FILHO AP & BADJI CA. 2018. Does cassava wastewater with a short incubation time affect soil organic carbon, microbial community and enzymatic activities? Catena 163: 354-360. also tested cassava wastewater in a microbial community in loco. After analyses of 28 days, they affirm that microorganisms, mainly the fungi population, have a high resilience to grown when cassava wastewater is employed. Suggesting that after 21 days the fungal comunity can hydrolyzed exuded cyanogenic glycosides found in cassava (Hall et al. 2015HALL AH, ISOM GE & ROCKWOOD GA. 2015. Toxicology of Cyanides and Cyanogens: Experimental, Applied and Clinical Aspects. John Wiley & Sons. In: Hamano PS & Kilikian BV (Eds), Production of red pigments by Monascus ruber in culture media containing corn steep liquor. Braz J Chem Eng 23: 443-449., Moura et al. 2018MOURA AS, MEDEIROS RV, OLIVEIRA JES, FRANCA RF, LIRA AD, MARTINS FILHO AP & BADJI CA. 2018. Does cassava wastewater with a short incubation time affect soil organic carbon, microbial community and enzymatic activities? Catena 163: 354-360.). Before 21 days the fungi comunity decrease. In our experiments we priorize a time reduction of incubation, because of that these wastewater was removed from the second part of the experiment.

In literature, satisfactory yield of biomass and bioproduct production, in different conditions where CSL is used as complementary nutritional source, are suggested due to their high concentration of nitrogen (Fang et al. 2010FANG TJ, LIAO B-C & LEE S-C. 2010. Enhanced production of xylanase by Aspergillus carneus M34 in solid-state fermentation with agricultural waste using statistical approach. N Biotechnol 27: 25-32., Hamano & Kilikian 2006, Oliveira et al. 2014, Berguer et al. 2018BERGUER LRR, STAMFORD TCM, OLIVEIRA KAR, PESSOA AMP, LIMA MAB, PINTADO MME, CÂMARA MPS, FRANCO LO, MAGNANI M & SOUZA EL. 2018. Chitosan produced from Mucorales fungi using agroindustrial by-products and its efficacy to inhibit Colletotrichum species. Int J Biol Macromol 108: 635-641.). Despite Berguer et al. (2018)BERGUER LRR, STAMFORD TCM, OLIVEIRA KAR, PESSOA AMP, LIMA MAB, PINTADO MME, CÂMARA MPS, FRANCO LO, MAGNANI M & SOUZA EL. 2018. Chitosan produced from Mucorales fungi using agroindustrial by-products and its efficacy to inhibit Colletotrichum species. Int J Biol Macromol 108: 635-641. suggested the mix of CSL and papaya peel juice (PPJ) as the better condition to fungal chitosan production we obtained a more economic condition with few milliliters of CSL in environment temperature to produce 7.8 g/kg of substrate with DD of 88.14%. The centesimal composition evaluation of total carbon source (17.57%) and total nitrogen (13.03%) in CSL used in culture media suggest that this fact may have influenced the fungi growth and the production of chitosan. Hofer et al. (2018)HOFER A, HAUER S, KROLL P, FRICKE J & HERWIG C. 2018. In-depth characterization of the raw material corn steep liquor and its bioavailability in bioprocesses of Penicillium chrysogenum. Process Biochem 70: 20-28. analyzed the influence of aminoacids in CSL to influence in fungi biomass and the bioproduct production. Based on literature we belive that the aminoacids present in CSL used during the experiments also influenced in biomass production. These fact is suggest by the high concentration of total nitrogen presented in the CSL sample used. Divergence among the CSL nutritional values here used and the literature can occur due to corn origin.

Nowadays, the modern statistical methods consider interactions of independent variables as an interference factor in the generation of a response product (Rufino et al. 2008RUFINO RD, SARUBBO LA, NETO BB & CAMPOS-TAKAKI GM. 2008. Experimental design for the production of tensio-active agent by Candida lipolytica. J Ind Microbiol Biotechnol 35: 907-914., Tinoco et al. 2011TINOCO R, ACEVEDO A, GALINDO E & SERRANO-CARREÓN L. 2011. Increasing Pleurotus ostreatus laccase production by culture medium optimization and copper/lignin synergistic induction. J Ind Microbiol Biotechnol 38: 531.). Among the different statistical methods, the simplest and most effective one for simultaneous analysis of interference variables, in a response product, is the complete factorial design (Beer et al. 1996BEER JO, VANDENBROUCKE CV, MASSART DL & DE SPIEGELEER BM. 1996. Half-fraction and full factorial designs versus central composite design for retention modelling in reversed-phase ion-pair liquid chromatography. J Pharm Biom Anal 14: 525-541.). In statistical evaluation of the results for chitosan production in CSL by complete factorial design, the coded level +1 for effect of initial pH corroborates with Pokhrel & Ohga results (2007POKHREL CP & OHGA S. 2007. Submerged culture conditions for mycelial yield and polysaccharides production by Lyophyllum decastes. Food Chem 105: 641-646.), which describe that the production of biomass and fungi bioproducts is favored in pH slightly alkaline in the range from 7.0 – 8.0.

After the fermentation processes, the final pH of all samples was measured, however, it was demonstrated that, independently of the initial pH, solutions tended to a final pH near 8.0. Furthermore, it was suggested that metabolic substances released for the culture medium may have favored such increase (Raya & Chakraverty 1998RAYA RR & CHAKRAVERTY R. 1998. Extracellular β-amylase from Syncephalastrum racemosum. Mycol Res 102: 1563-1567.) (Table II). The non-adjustment of pH during the fermentative process is proposed (Feng et al. 2010FENG Y-L, LI W-Q, WU X-Q, CHENG JW & MA SY. 2010. Statistical optimization of media for mycelial growth and exo-polysaccharide production by Lentinus edodes and a kinetic model study of two growth morphologies. Biochem Engin J 49: 104-112.) because it makes difficult biopolymer production.

In regard to the analysis of temperature influence, regulation of morphogenetic factor in fungi is described. High temperature is associated to yeast form development and to low temperatures with filamentous development (Bartnicki-Garcia & Nickerson 1962BARTNICKI-GARCIA S & NICKERSON WJ. 1962. Nutrition, growth, and morphogenesis of Mucor rouxii. J Bacteriol 84: 841-846.). As described in the results, the largest chitosan production occurred when incubation temperature was at 25 °C, which was associated to filamentous development of S. racemosum and, consequently, accumulation of large quantities of chitosan in the fungal cell wall (Baker et al. 2007BAKER LG, SPECHT CA, DONLIN MJ & LODGE JK. 2007. Chitosan, the deacetylated form of chitin, is necessary for cell wall integrity in Cryptococcus neoformans. Eukaryotic Cell 6: 855-867.). Despite there has not been observed increase in yeast form for conditions of high temperature (37 °C), stability of morphogenetic growth as filaments at 25 °C may have favored accumulation of larger quantities of chitosan in the fungal cell wall.

Coded level -1 for inoculum size, corresponding to final real value in solution of 100 sporangioles/mL, corroborates with Bartinicki-Garcia & Nickerson (1962) which suggest that high concentrations of inoculum do not favor biomass and chitosan production in fungi.

The best condition of microbiological chitosan production was obtained through 2% (v/v) CSL concentrated condition, initial pH 8.0, inoculum size 100 sporangioles/mL and incubation temperature at 25 °C. Under such condition, chitosan production was of 62.44 mg/g of dry biomass, or 7.8 g/kg of concentrated substrate, surpassing result attained by Wang et al. (2008)WANG W, DUA Y, QIU Y, WANG X, HU Y, YANG J, CAI J & KENNEDY JF. 2008. A new green technology for direct production of low molecular weight chitosan. Carbohydr Polym 74: 127-132, which obtained 6.12 g/kg of CSL 1% (v/v) substrate plus molasses using Absidia coeruela. However, result attained in the present study was inferior to the one from Amorim et al. (2006)AMORIM RSV, LENDIGHAM WM, KENNEDY JF & CAMPOS-TAKAKI GM. 2006. Chitosan from Syncephalastrum racemosum using sugar cane substrates as inexpensive carbon sources. Food Biotechnol 20: 43-53., which obtained 74 mg/g of dry biomass when S. racemosum was grown in sugar cane juice supplemented by 0.3% of yeast extract.

Fermentative processes for production of bioproducts are described as having easy standardization (Arcidiacono & Kaplan 1992ARCIDIACONO S & KAPLAN DL. 1992. Molecular weight distribution of chitosan isolated from Mucor rouxii under different culture and processing conditions. Biotechnol Bioeng 39: 281-286.). Characterization of the produced bioproduct by S. racemosum in the conditions pre-determined by complete factorial design confirmed that high quality chitosan was obtained, being probable its use in different biotechnological processes. During characterization tests, deacetylation degree (DD) of 88.14% is confirmed by European Chitin Society (EUCHIS) as commercializable chitosan (Tajik et al. 2008TAJIK H, MORADI M, ROHANI SMR, ERFANI AM & JALALI FSS. 2008. Preparation of chitosan from brine shrimp (Artemia urmiana) cyst shells and effects of different chemical processing sequences on the physicochemical and functional properties of the product. Molecules 13: 1263-1274.). Crystalline condition of microbiologicalchitosan suggests that it presents few protonated groups in its molecular chain and a larger quantity of structural intermolecular bonds among amino groups of residues (Focher et al. 1990FOCHER B, BELTRAME PL, NAGGI A & TORRI G. 1990. Alkaline N-deacetylation of chitin enhanced by flash treatments: Reaction kinetics and structure modifications. Carbohydr Polym 12: 405-418., Guibal 2004GUIBAL E. 2004. Interactions of metal ions with chitosan-based sorbents: a review. Sep Purif Technol 38: 43-74., Wang et al. 2008WANG W, DUA Y, QIU Y, WANG X, HU Y, YANG J, CAI J & KENNEDY JF. 2008. A new green technology for direct production of low molecular weight chitosan. Carbohydr Polym 74: 127-132), when compared to commercial chitosan used as standard.

Comparison among thermal parameters evaluated for the characteristics of microbiological and commercial chitosan confirmed that high crystallinity of microbiological chitosan is associated to the presence of many bonds of intermolecular hydrogen and with the largest quantity of cyclical structures present in molecular structure of microbiological chitosan, when compared to commercial chitosan used during the experiment as standard (Wang et al. 2008WANG W, DUA Y, QIU Y, WANG X, HU Y, YANG J, CAI J & KENNEDY JF. 2008. A new green technology for direct production of low molecular weight chitosan. Carbohydr Polym 74: 127-132, Yen & Mau 2007YEN M-T & MAU J-L. 2007. Physico-chemical characterization of fungal chitosan from shiitake stipes. LWT 40: 472-479.).

The results obtained in this study suggest a great potential to widen chitosan production by S. racemosum in culture medium of low cost with maintenance of physical-chemical characteristics of microbiological chitosan. For fermentation success, it is pointed out the association of independent factors (initial pH, incubation temperature and inoculum size), which influence the polymer production in S. racemosum cell wall. Incubation for 36 h without meaningful loss of chitosan productivity and quality is suggested to favor time saving and cost reduction embedded in culture maintenance in submerged system. Another important advantage in the use of agroindustrials wastes, as green technological substrate, refers to its contribution to cost reduction of microbiological chitosan production and its aid while decreasing residual disposal without environmental treatment.

At the end we suggest that our methodology to produce fungal chitosan has a promise condition to compete economically with industries fungal chitosan as Mycodev®, in Canada, Kytozime®, in Belgium, InvivoGen®, United States of America, Beijing Wisapple Biotech Co., China, and others.

ACKNOWLEGMENTS

Authors are thankful to local industry, in Pernambuco, for having kindly provided raw wastewaters from its production for study; to Federal University of Paraíba; to Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) through doctorate’s scholarship to the first author; to Financiadora de Estudos e Projetos (FINEP); to Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq); the Fundação de Amparo a Ciência e Tecnologia do Estado de Pernambuco (FACEPE); and to Catholic University of Pernambuco (UNICAP). This article does not contain any studies with human participants performed by any of the authors and the authors declare that they have no competing interests.

REFERENCES

- ABDEL-GAWAD KM, HINEY AF, FAWZY MA & GOMAA M. 2017. Technology optimization of chitosan production from Aspergillus niger biomass and its functional activities. Food Hydrocolloids 63: 593-601.

- AMORIM RSV, LENDIGHAM WM, KENNEDY JF & CAMPOS-TAKAKI GM. 2006. Chitosan from Syncephalastrum racemosum using sugar cane substrates as inexpensive carbon sources. Food Biotechnol 20: 43-53.

- ARCIDIACONO S & KAPLAN DL. 1992. Molecular weight distribution of chitosan isolated from Mucor rouxii under different culture and processing conditions. Biotechnol Bioeng 39: 281-286.

- BAKER LG, SPECHT CA, DONLIN MJ & LODGE JK. 2007. Chitosan, the deacetylated form of chitin, is necessary for cell wall integrity in Cryptococcus neoformans. Eukaryotic Cell 6: 855-867.

- BALDRICK P. 2010. The safety of chitosan as a pharmaceutical excipient. Regul Toxicol Pharmacol 56: 290-299.

- BARTNICKI-GARCIA S & NICKERSON WJ. 1962. Nutrition, growth, and morphogenesis of Mucor rouxii. J Bacteriol 84: 841-846.

- BATISTA ACL, FREITAS SILVA MC, BATISTA JB, NASCIMENTO AE & CAMPOS-TAKAKI GM. 2013. Eco-Friendly Chitosan Production by Syncephalastrum racemosum and Application to the Removal of Acid Orange 7 (AO7) from Wastewaters. Molecules (Basel. Online) 18: 7646-7660.

- BEER JO, VANDENBROUCKE CV, MASSART DL & DE SPIEGELEER BM. 1996. Half-fraction and full factorial designs versus central composite design for retention modelling in reversed-phase ion-pair liquid chromatography. J Pharm Biom Anal 14: 525-541.

- BERGUER LRR, STAMFORD TCM, OLIVEIRA KAR, PESSOA AMP, LIMA MAB, PINTADO MME, CÂMARA MPS, FRANCO LO, MAGNANI M & SOUZA EL. 2018. Chitosan produced from Mucorales fungi using agroindustrial by-products and its efficacy to inhibit Colletotrichum species. Int J Biol Macromol 108: 635-641.

- BRADBURY J-H, EGAN SV & LYNCH MJ. 1991. Analysis of cyanide in cassava using acid hydrolysis of cyanogenicglucosides. J Sci Food Agric 55: 277-290.

- CAMPOS-TAKAKI GM. 2005. The fungal versatility on the copolymers chitin and chitosan productionp. In: Dutta PK (Ed), Chitin and Chitosan Opportunities and Challenges. SSM International Publication, Midnapore, India, p. 69-94.

- CUNNIFF P. 1995. Official Methods of Analysis of the Association of Official Analytical Chemists (method 958.06). Arlington, VA, p. 21.

- DOS SANTOS E, FREITAS SILVA MC, SOUZA PM, SILVA AC, PAIVA SC, ALBUQUERQUE CDC, NASCIMENTO AE, OKADA K & CAMPOS-TAKAKI GM. 2013. Enhancement of Cunninghamella elegans UCP/WFCC 0542 Biomass and Chitosan with Amino Acid Supply. Molecule (Basel.Online) 18: 10095-10107.

- EL-SAWY NM, EL-REHIM, HAA, ELBARBARY AM & HEGAZY E-SA. 2010. Radiation-induced degradation of chitosan for possible use as a growth promoter in agricultural purposes. Carbohydr Polym 79: 555-562.

- FANG TJ, LIAO B-C & LEE S-C. 2010. Enhanced production of xylanase by Aspergillus carneus M34 in solid-state fermentation with agricultural waste using statistical approach. N Biotechnol 27: 25-32.

- FASCIOTTI M. 2017. Perspectives for the use of biotechnology in green chemistry applied to biopolymers, fuels and organic synthesis: from concepts to acritical point of view. Sust Chem Pharm 6: 82-89.

- FENG Y-L, LI W-Q, WU X-Q, CHENG JW & MA SY. 2010. Statistical optimization of media for mycelial growth and exo-polysaccharide production by Lentinus edodes and a kinetic model study of two growth morphologies. Biochem Engin J 49: 104-112.

- FOCHER B, BELTRAME PL, NAGGI A & TORRI G. 1990. Alkaline N-deacetylation of chitin enhanced by flash treatments: Reaction kinetics and structure modifications. Carbohydr Polym 12: 405-418.

- GHOSH B & RAY RR. 2011. Extra-cellular Isoamylase Production by Rhizopus oryzae in Solid-State Fermentation of Agro Wastes. Braz Arch BiolTechnol 54: 867-876.

- GUIBAL E. 2004. Interactions of metal ions with chitosan-based sorbents: a review. Sep Purif Technol 38: 43-74.

- HALL AH, ISOM GE & ROCKWOOD GA. 2015. Toxicology of Cyanides and Cyanogens: Experimental, Applied and Clinical Aspects. John Wiley & Sons. In: Hamano PS & Kilikian BV (Eds), Production of red pigments by Monascus ruber in culture media containing corn steep liquor. Braz J Chem Eng 23: 443-449.

- HOFER A, HAUER S, KROLL P, FRICKE J & HERWIG C. 2018. In-depth characterization of the raw material corn steep liquor and its bioavailability in bioprocesses of Penicillium chrysogenum. Process Biochem 70: 20-28.

- HU K-J, YEUNG KW, HO KP & HU J-L. 1999. Rapid extraction of high-quality chitosan from mycelia of Absidia glauca. J Food Biochem 23: 187-196.

- IBRAHIM M, TAO Z, HUSSAIN A, CHUNLAN Y, ILYAS M, WAHEED A, YUN F, LI B & XIE G-L. 2014. Deciphering the role of Burkholderia cenocepacia membrane proteins in antimicrobial properties of chitosan. Arch Microbiol 196: 9-16.

- KUMIRSKA J, CZERWICKA M, KACZYŃSKI Z, BYCHOWSKA A, BRZOZOWSKI K, THÖMING J & STEPNOWSKI P (2010). Application of spectroscopic methods for structural analysis of chitin and chitosan. Marine Drugs 8: 1567-1636

- LABCONCQ. 2005. To Kjeldahl Nitrogen determination methods and apparatus. ExpotechUSA. Houston, Texas, USA. http://www.expotechusa.com/catalogs/labconco/pdf/KJELDAHLguide.PDF Acessed 06 July 2008.

» http://www.expotechusa.com/catalogs/labconco/pdf/KJELDAHLguide.PDF - MAHOPATRA S, MAITY S, DASH HR, DAS S, PATTNAIK S, RATH CC & SAMANTARAY D. 2017. Bacillus and biopolymer: Prospects and challenges. Biochem Biophys Rep 12: 206-213.

- MATSUZAWA T, CAMPOS-TAKAKI GM, YAGUCHI T, OKADA K, GONOI T & HORIE Y. 2014.Two new species of Aspergillus section Fumigati isolated from caatinga soil in the State of Pernambuco, Brazil. Mycoscience 55: 79-88.

- MOURA AS, MEDEIROS RV, OLIVEIRA JES, FRANCA RF, LIRA AD, MARTINS FILHO AP & BADJI CA. 2018. Does cassava wastewater with a short incubation time affect soil organic carbon, microbial community and enzymatic activities? Catena 163: 354-360.

- MUZZARELLI RAA & PETER MG. 1997. Chitin handbook. AtecEdizioni, Grottammare Oliveira CEV, Magnani M, Sales CV, Pontes ALS, Campos-Takaki GM, Stamford TCM & Souza EL (Eds), Effects of post-harvest treatment using chitosan from Mucor circinelloides on fungal pathogenicity and quality of table grapes during storage. Food Microbiol 44: 211-219.

- POKHREL CP & OHGA S. 2007. Submerged culture conditions for mycelial yield and polysaccharides production by Lyophyllum decastes. Food Chem 105: 641-646.

- RAYA RR & CHAKRAVERTY R. 1998. Extracellular β-amylase from Syncephalastrum racemosum. Mycol Res 102: 1563-1567.

- RUFINO RD, SARUBBO LA, NETO BB & CAMPOS-TAKAKI GM. 2008. Experimental design for the production of tensio-active agent by Candida lipolytica. J Ind Microbiol Biotechnol 35: 907-914.

- SCHMIDELL W. 2001. Microrganismos e meios de cultura para utilização industrial. In: Schmidell W, Lima UA, Aquarone E & Borzani W (Ed), Biotecnologia Industrial Vol. 2. Edgard Blücher, São Paulo, p. 5-18.

- SILVA AC, GUIMARÃES PMR, TEIXEIRA JA & DOMINGUES L. 2010. Fermentation of deproteinized cheese whey powder solutions to ethanol by engineered Saccharomyces cerevisiae: effect of supplementation with corn steep liquor and repeated-batch operation with biomass recycling by flocculation. J Ind Microbiol Biotechnol 37: 973-982.

- STATISTICA. 2004. Version 7, StatSoft, Inc. http://www.statsoft.com

» http://www.statsoft.com - TAJIK H, MORADI M, ROHANI SMR, ERFANI AM & JALALI FSS. 2008. Preparation of chitosan from brine shrimp (Artemia urmiana) cyst shells and effects of different chemical processing sequences on the physicochemical and functional properties of the product. Molecules 13: 1263-1274.

- TASAR OC, ERDAL S & TASKIN M. 2016. Chitosan production by psychrotolerant Rhizopus oryzae in non-sterile open fermentation conditions. International Journal of Biological Macromolecules 89: 428-433.

- TERBOJEVICH M & COSANI A. 1997. Molecular weight determination of chitin and chitosan. In: Muzzarelli RAA & Peter MG (Eds), Chitin Handbook. AtecEdizioni, Grottammare, p. 87-101.

- TINOCO R, ACEVEDO A, GALINDO E & SERRANO-CARREÓN L. 2011. Increasing Pleurotus ostreatus laccase production by culture medium optimization and copper/lignin synergistic induction. J Ind Microbiol Biotechnol 38: 531.

- WANG W, DUA Y, QIU Y, WANG X, HU Y, YANG J, CAI J & KENNEDY JF. 2008. A new green technology for direct production of low molecular weight chitosan. Carbohydr Polym 74: 127-132

- YEN M-T & MAU J-L. 2007. Physico-chemical characterization of fungal chitosan from shiitake stipes. LWT 40: 472-479.

- ZHANG H, YANG S, FANG J, DENG Y, WANG D & ZHAO Y. 2014. Optimization of the fermentation conditions of Rhizopus japonicus M193 for the production of chitin deacetylase and chitosan. Carbohydr Polym 101: 57-67.

Publication Dates

-

Publication in this collection

01 June 2020 -

Date of issue

2020

History

-

Received

26 Aug 2018 -

Accepted

19 Dec 2018