Abstract

The reutilization of waste is a valuable alternative for the preservation of natural resources and the environment. In this sense, Basic Oxygen Furnace (BOF) steel slag is one of the most residues generated in steel the industry. It is estimated that for each ton of steel produced, about 150 kg of steel slag is generated in the BOF process. Generally, the newly produced BOF steel slag is volumetrically unstable, presenting expansive characteristics, and for this reason, its application should be based on stabilization studies. The main objective of this research was to analyze the chemical stabilization process of BOF steel slag by means of carbonation of the material. For this purpose, an experimental method based on hydration and carbonation in 2-meter high slag piles, moistened with sprinklers and instrumented with leaf wetting, temperature, precipitation and carbon dioxide content sensors was used. A control stack was also set up to accompany the stabilization process through the conventional procedure, in which the material is disposed of in large stacks and subjected to the weather conditions for long periods. The laboratory campaigns were developed in the laboratories of the Federal University of Ouro Preto. Thus, through the results obtained, it was possible to conclude that the stabilization method based on hydration and carbonation for the BOF steel slag was efficient, reducing the free lime content to values well below those prescribed internationally.

Keywords:

basic oxygen furnace slag; volumetric expansion; stabilization; carbonation; ballast

1. Introduction

The relevance of issues related to environmental conservation in the various segments of economic activity and government policies has been growing significantly in recent decades. This growth is stimulated by society's environmental awareness and by increasingly demanding environmental legislation. Thus, many companies in various sectors seek to train their technical employees and invest in the establishment of new equipment in order to minimize the waste culture and promote appropriate methodologies for the recycling of waste generated in their production processes. One of the main results which can be emphasized is that stabilized slag has great potential to be applied as railway ballast in signaled tracks in terms of mechanical and chemical behavior.

A proposal to mitigate environmental impact and pursue sustainable development is the reuse of waste. The area of railroad paving is a promising sector for the recycling of waste for a number of factors. First, reducing the volume of material that would be stored in industrial yards and landfills would convert impacts and investments into new applications and additional revenue. Secondly, the use of waste in paving would provide a reduction in some natural inputs that are extracted from deposits or mines, which often do not have environmental licenses and act without concern for the environment. And finally, there can be mentioned the improvements provided by the addition of some agricultural and industrial waste, both from the point of view of mechanical properties and durability, to traditional paving materials (Wang et al. 2010WANG, G.; WANG, Y.; GAO, Z. Use of steel slag as a granular material: volume expansion prediction and usability criteria. Journal of Hazardous Materials , v. 184, n.1-3, p. 555-560, Dec. 2010.; Gao et al. 2017GAO, J.; SHA, A.; WANG, Z.; TONG, Z.; LIU, Z. Utilization of steel slag as aggregate in asphalt mixtures for microwave deicing. Journal of Cleaner Production , v. 152, p. 429-442, May 2017.)). From a financial point of view, viability is linked to the amount of waste available; in this point, the steel industry stands out. Despite increasingly seeking to invest in equipment and the formation of technical staff capable of solving environmental problems, it continues to generate a large amount of waste (Masuero et al., 2001MASUERO A. B. Estabilização das escórias de aciaria elétrica com vistas a sua utilização como substituição ao cimento . 2001. 264 f. Tese (Doutorado em Engenharia) - Escola de Engenharia, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2001.).

Among these residues the slag generated in steel production can be highlighted, since it has a high generation, expansive character and is stored in open areas, or when used, does not have quality control. These characteristics are responsible for the appearance of unwanted manifestations in the applications in which they were incorporated (Topkaya et al. 2004TOPKAYA, Y.; SEVINC, N.; GUNAYDIN, A. Slag treatment at Kardemir integrated iron and steel works. International Journal of Mineral Processing , v. 74, n. 1-4, p. 31-39, Nov. 2004.; Dippenaar 2005DIPPENAAR, R. Industrial uses of slag (the use and re-use of iron and steelmaking slags). Ironmaking & Steelmaking , v. 32, n.1, p. 35-46, 2005.; Fernandes, 2010FERNANDES, D. P. Estudo de estabilização química, geo-mecânica e ambiental das escórias de aciaria LD para fins de aplicação como material de lastro ferroviário em vias sinalizadas . 2010. 142 f. Dissertação (Mestrado em Geotecnia) - Núcleo de Geotecnia, Escola de Minas, Universidade Federal de Ouro Preto, Ouro Preto, 2010.).

The use of BOF steel slag as aggregate or rail ballast material is hampered by the possibility of volumetric expansion. These expansive reactions occur involving certain compounds present in the steel slag, generating internal stresses that cause cracks and even result in the fragmentation of the material, in a destructive expansion. Among these volumetrically unstable compounds, CaO and MgO are the most relevant and largest responsible for the disintegration and weakening due to molar volume difference in their reactions (Motz and Geiseler, 1998MOTZ, H.; GEISELER, J. The steel slags: properties, properties and quality assurance. In: EUROPEAN SLAG CONFERENCE, 1998, Marseilles, France. Proceedings […] . [S. l.: s. n.], 1998. p. 149-168. (Iron and Steel Slags - Properties and utilization).; Gumieri et al. 2000; Ângulo et al. 2001ÂNGULO, S. C.; ZORDAN, S. E.; JONH, V. M. Desenvolvimento sustentável e a reciclagem de resíduos na construção civil. In: SEMINÁRIO DESENVOLVIMENTO SUSTENTÁVEL E A RECICLAGEM NA CONSTRUÇÃO CIVIL, 4., 2001, São Paulo. Anais […] . São Paulo: IBRACON - CT206, 2001.).

It is considered that the high free lime content is the main responsible for the problem of expansion of steel slag; there are several studies aimed at limiting its content as a criterion for classification and application of slag. These studies show that, at levels below 7 %, free lime may not be detrimental to the durability of pavements applying BOF steel slag. However, other sources do not adopt this criterion, preferring to use as tolerance limit a free lime content between 4 and 5%. Thus, what can be observed is that steel slag BOF presents a high dimensional instability generated mainly by high free lime contents - above 5% (Montgomery and Wang, 1991MONTGOMERY, D. G.; WANG, G. Instant-chilled steel slag aggregate in concrete: strength related properties. Cement and Concrete Research , v. 21, n. 6, p. 1083-91, 1991b.).

Several researches are developed with the main objective of evaluating the reuse of steel slag. Most of the steel slag is applied in the form of aggregates, in soil stabilization, in railway ballast, contentions executed with gabions and rockfill, construction of bases, sub-bases and asphalt coating of highways, as well as materials for landfills and hydraulic works. Several authors, among them Gutt (1972)GUTT, W. Agregates from waste materials. Chemistry and Industry , V. 49, p. 439-447, Jun. 1972., Emery (1978)EMERY, J. J. Utilisation des scories d’aciérie dans la construction des autoroutes canadiennes. Revue de Métallurgie , Paris, v. 75, n.5, p. 303-310, mai 1978., and Holliday (1997)HOLLIDAY, K. A. Steel slag: the high performance industrial aggregate. Steel World , v. 2, n. 1, p.11-14, 1997., evaluated the use of steel slag in these types of works.

In some countries such as England, Germany, France, Japan, Russia, and the United States there are already standardizations regarding the use of steel slag (Fernandes, 2016FERNANDES, D. P. Metodologia para estabilização química do agregado siderúrgico para aplicação como lastro ferroviário . 2016. 224 f. Tese (Doutorado em Geotecnia) - Núcleo de Geotecnia, Escola de Minas, Universidade Federal de Ouro Preto, Ouro Preto, 2016.). Countries such as Japan, Canada, Australia, and some European countries already show considerable rates for use of steel slag in engineering works, mainly in the paving area (Motz and Geiseler, 2001MOTZ, H.; GEISELER, J. Products of steel slags an opportunity to save natural resources. Waste Management , v. 21, n. 3, p. 285-293, Jun. 2001.). Hirano (1984)HIRANO, Y. How to expand the market for BOF slags in Japan. In: COMMITTEE ON ENVIRONMENTAL AFFAIR. Utilization of blast furnace and bof slag . Brussels, Belgium: International Iron and Steel Institute, 1984. section A2, p. 32- 43. emphasizes that steel slag rich in CaO and MgO is used in Japan as a soil conditioner for acid soils. Iron, phosphorous and a variety of minerals contained in the slag have favorable effects in agriculture, since there are no heavy metals. In Brazil, the rates are relatively low in engineering works, considering that more than half of the total volume of steel slag generated is used for the manufacture of cement (Fernandes, 2016FERNANDES, D. P. Metodologia para estabilização química do agregado siderúrgico para aplicação como lastro ferroviário . 2016. 224 f. Tese (Doutorado em Geotecnia) - Núcleo de Geotecnia, Escola de Minas, Universidade Federal de Ouro Preto, Ouro Preto, 2016.).

Since the nineties, many studies have been developed by universities, in partnership with some national steel companies, aiming at the use of BOF steel slag in the civil construction sector, in paving and as an aggregate for railway ballast. The results are exposed in the works of Geyer (2001)GEYER, R. M. T. Estudo sobre a potencialidade de uso das escórias de aciaria como adição ao concreto . 2001. 145 f. Tese (Doutorado em Engenharia) - Escola de Engenharia, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2001., Masuero (2001)MASUERO A. B. Estabilização das escórias de aciaria elétrica com vistas a sua utilização como substituição ao cimento . 2001. 264 f. Tese (Doutorado em Engenharia) - Escola de Engenharia, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2001., Santos et al. (2012)SANTOS, R. M.; LING, D.; SARVARAMINI, A.; GUO, M.; ELSEN, J.; LARACHI, F.; BEAUDOIN, G.; BLANPAIN, B.; VAN GERVEN, T. Stabilization of basic oxygen furnace slag by hot-stage carbonation treatment. Chemical Engineering Journal , v. 203, p. 239-250, Sep. 2012., among several others. Another example of this partnership between steel companies and universities seeking to stabilize steel slag is LiDonit, a by-product generated by ThyssenKrupp, for road-based employment.

In view of the above, the proposal of this research to develop alternative methods to stabilize steel slag is very beneficial to the industry that currently uses a delayed technique based only on hydration without control of the amount of water used and also unregulated height of the slag piles for treatment, which causes undesired heterogeneity in the material, especially if the reuse is in railway ballast. In this technique, a geometric configuration is used to regulate the maximum height of the slag cone and a controlled amount of water so that the material develops the stabilization reactions without forming locations of untreated slag. In other words, this method avoids heterogeneity, obtaining greater efficiency in the process and allows a better control of the water volume, minimizing costs with wastewater treatment.

Hence, the search for new materials for railroad paving, together with the need for the steel industry to reuse the production of its waste, constitutes a great effort to achieve Sustainable Development.

2. Materials and methods

To conduct this research, the BOF steel slag was subjected to a chemical stabilization treatment, which consisted of hydration and carbonation of the material by means of sprinklers connected to a hydraulic pump. The sprinkler system has been programed to provide a wetting of the slag pile with a duration of seven minutes every thirty minutes. The material studied was arranged in the geometric shape of cones. The tarpaulin-covered pile received water from the hydraulic system, while the air-exposed pile received only rainwater. Thus, 2 piles of fresh or newly produced BOF steel slag were assembled. Figure 1 illustrates more clearly the system installed.

Arrangement of experimental stacks. The HCS stack is covered with canvas, while the CS battery is exposed on the environment.

Both stacks assembled for the experiment had the geometric model recommended by the technical reference. The arrangements had a geometric cone shape with a height of 2.00 m; diameter of 6.00 m; spacing angle of 33.66º; geratrix of 3.60m. The lateral area was 34.00 m2 with a total area of 62.30 m2 totaling a volume of 18.84 m3 and utilizing a real density of the grains of scurvy of 3.39 g/cm3; the mass of the disposition was 63.8676 t. The nomenclature of the studied piles is: Hydrated and Carbonated Slag (HCS), for the material that was covered by the canvas; Control Slag (CS), for the aggregate that will be submitted only to the local adversities, as rain, for example.

The location where the experimental research program was developed is the courtyard of the steel industry producing the studied slag. The period in which the slag was submitted to the described treatment was 4 (four) months. Samples were collected every 15 days in both piles and the expansion process was controlled by means of a modified PTM-130 test and by a free lime content test. The monitoring of the environmental conditions of the research area was done through leaf wetting sensors, temperature, carbon dioxide (CO2) content and rain gauge, installed at the base and middle of the piles layer and connected to an electrovoltaic cell and also to a datalogger. Figure 2 shows photos with the temperature and leaf wetting sensors and the rain gauge used.

The HCS cell was carbonated from the atmospheric carbon dioxide present in the industrial plant where the experiment was carried out, so the stack was covered with canvas. Because of this, the concentration of carbon dioxide inside the tarpaulin pile was measured.

Regarding the size of the slag particles evaluated both in the HCS pile and in the CS, it is necessary to emphasize that at the beginning of the experiment both were in the appropriate granulometry for ballast. At the end of the stabilization period both piles were sampled and the granulometry test was performed to understand if there was much fragmentation of the material.

2.1 Chemical characterization of hydrated carbonated slag (HCS) and control slag (CS)

The chemical characterization assays were performed on samples of hydrated carbonated slag (HCS), and control slag (CS) after the crushing process (jaw crusher) with a granulometric classification below the # 200 sieve or with an aperture equal to 0.074mm.

For the evaluation of the free lime content in the analyzed HCS and CS samples, the Free Calcium Oxide Determination by the Ethylene Glycol Method (ABNT/NBR-7227/1989ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ABNT NBR 7227 : Cimento Portland: determinação de óxido de cálcio livre pelo etileno glicol: método de ensaio. Rio de Janeiro: ABNT, 1989.), was used. This standard indicates the evaluation of free calcium oxide by dissolution in ethylene glycol and subsequent titration in standard solution of hydrochloric acid (HCl), using a mixed solution as indicators of pH (methyl red and bromocresol green). The test was performed in triplicate.

The assessment of MgO content is out of scope of this research, since it is a long-term expansion and requires much more time to cause a problem in rail ballast. However, the method used of carbonation and hydration has the potential to reduce the concentration of MgO in slag according to recent research.

2.2 Expansibility evaluation of hydrated carbonated slag (HCS) and control slag (CS)

The PTM 130/78 expansion test was designed from studies conducted by Emery (1978)EMERY, J. J. Utilisation des scories d’aciérie dans la construction des autoroutes canadiennes. Revue de Métallurgie , Paris, v. 75, n.5, p. 303-310, mai 1978. at MacMaster University (Ontario/Canada). Then, with a change in the temperature used and in the test period, the ASTM 4792/00 standard was created. Soon after, the Department of Highways of Minas Gerais developed an adaptation to the original method of PTM 130/78 originating the test DMA - 1/ DER - MG /92.

The DMA - 1/DER - MG/92 test is summarized in the immersion of cylindrical specimens compacted in normal Proctor energy in a thermal bath with water at 71 ± 3ºC for a period of 7 days, with daily readings of the volumetric variation as a function of the increase in height of the specimen. Afterwards, the specimens are removed from the thermal bath and taken to an electric oven at the same temperature of 71 ± 3ºC. The test method dictates that the specimen must be kept in the "saturation" condition (not submerged) for a further seven days, with daily readings of the expansion being taken for the same period. For this test, in particular, a modification in the mounting of the specimens is necessary, since the stabilized slag is in the particle size range for railway ballast and therefore needs to be compacted in normal Proctor energy, with chemically stabilized BOF steel slag powder to obtain a stable cylinder, without lateral movement of the particles. In this study, a mass combination of 70% material in the particle size range for ballast and 30% powder was used to fill the cylinder and make it stable for the test. The test was performed in triplicate.

The percentage of total volumetric expansion is that obtained after 14 days. The limit established by DNIT-PRO 262/94 for each test is 3% for cumulative expansion after 14 test days. Masuero et al., (2001)MASUERO A. B. Estabilização das escórias de aciaria elétrica com vistas a sua utilização como substituição ao cimento . 2001. 264 f. Tese (Doutorado em Engenharia) - Escola de Engenharia, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2001. complements such specifications and suggests that the batch of steel slag should only be accepted when the expansion of all specimens tested for each sample is below the 3% limit by the PTM-130/78 method.

2.3 Analysis of the mechanical behavior in the hydrated carbonated slag (HCS) and control slag (CS)

In the laboratory phase, the following tests were performed: Granulometry Test (ASTM D5519-15), Los Angeles Abrasion Test (ASTM C131/C131M-14), Shock Resistance Test - NBR 8938 - Determination of Shock Resistance (ABNT, 1985ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ABNT NBR 8938 : Lastro padrão: determinação da resistência ao choque: método de ensaio. Rio de Janeiro: ABNT , 1985.). The tests described in this topic were carried out in the laboratories of the Department of Civil Engineering of the School of Mines, Federal University of Ouro Preto, mainly in the dependencies of the Laboratory of Railways and Asphalt.

3. Results

3.1 Monitoring of field environmental conditions

The objective of this study was to submit the BOF steel slag to a treatment process based on timed hydration and carbonation of the HCS stack and monitor the stabilization development of the material by means of a data collection and field monitoring system. The data collection system implemented in an HCS pile in the processing yard of the BOF steel slag were composed of leaf wetting, temperature and precipitation sensors, as well as the carbon dioxide content (CO2).

The monitoring of precipitation occurring in the processing yard is presented in Figure 3. This graph was obtained by means of a rain gauge installed next to the sprinkler system enabling the automatic and continuous monitoring of rainfall volume providing data of maximum, minimum and average intensity of rainfall in the period of four months. The purpose was to verify the amount of water that the Control pile would receive from precipitation.

The rainfall registers collected during the monitoring period (four months) showed that in the summer season there was the greatest amount of rainfall with volumes ranging from 2 to 21 mm. After the summer season, isolated rainfall occurred with negligible volumes. The heaviest rainfall event reaching 7mm in winter. The total precipitated during the monitoring period was 372 millimeters. The precipitation data are relevant to compare the expansion values and the lime content of the studied materials obtained through mechanized sprinkling implemented in the HCS pile and by precipitation in the pile Control.

Figure 4 presents the temperature in the HCS and Control stack through the installed sensors.

It is possible to notice that throughout the monitoring period, the materials had high temperatures, evincing a positive contribution to the kinetics of hydration and carbonation reactions that occurred in the analyzed materials.

In this experimental campaign, field measurements were also carried out regarding the carbon dioxide (CO2) content present in the HCS area and Control piles, as well as inside the canvas used in the carbonation process of the material.

Figure 5 shows the carbon dioxide (CO2) content that was recorded in each field collection in the slag processing yard. This value was measured by means of the carbon dioxide meter, positioned at the top of the HCS and Control stacks.

The figure shows that there was a significant drop in the CO2 content present inside the HCS pile. This fact can be related to the occurrence of the carbonation reaction that transforms free calcium oxide into calcium carbonate in the reaction with CO2 and contributes to reduce the expansion of the material. For the Control stack, no values were recorded that would point to a possible carbonation reaction in the slag. Thus, it is also observed that the CO2 levels for the HCS cell varied between 150 and 360 ppm, values indicating that the HCS cell aggregate was reacting with the CO2 present inside the canvas.

3.2 Chemical characterization of hydrated carbonated slag (HCS) and control slag (CS) samples

The results obtained for the free lime content test are presented in Figure 6.

Through the results presented, it was possible to notice a significant reduction in the free lime content present in the HCS sample throughout the monitoring period. This fact is due to the hydration and carbonation reaction, which was increased by the carbon dioxide that was retained around the pile with the tarpaulin placed. It is also clear that the CS sample did not present a significant reduction in the free lime content during the experimental work, reinforcing the understandable that it is necessary to promote moistening in a timely manner for the oxides to react and stabilize. It is important to highlight that the HCS sample complied with the 3% limit set by Arema and other international standards, such as the Japanese JIS A 5015 (Japan Institute Standard, 1992) and the European standard BS EN 1744-1 (European Standard, 1998).

Another relevant issue was the speed in the stabilization process, with 4 months of treatment the HCS sample was already with a free lime content below 1% while the control sample was with more than 5%. The time required for the Control stack to achieve compliance with the same Japanese standard is 6 months to 1 year. However, without an adequate geometric configuration and timing control of the water utilization, the sample may show heterogeneity in relation to the free lime content.

3.3 Expansibility evaluation of hydrated carbonated slag (HCS) and control slag (CS)

The results of the assays are presented in Figure 7. The tests were performed every 15 days according to the collection performed in the HCS and Control piles presenting the total monitoring period for PTM-130/78.

The results of the PTM-130 assay demonstrated that the HCS and Control cells started with a high expansion at the end of the fourteen days of measurements. However, as the treatment with hydration and carbonation in the piles developed, the expansive behavior of the material was decreasing; and after 45 days of treatment, it was below the recommended by norm, which is 3%. Thus, it is evident that the expected reactions by hydration and carbonation occurred, which modified the expansive character that the material presented without treatment. Figure 8 presents a sequence of photos to illustrate the expansion caused by the treatment and the passage of water through the particle of steel slag.

Photos of HCS stack illustrating the expansion and process of hydration and carbonation stabilizing the material.

Since it did not receive specific treatment and was only subjected to local weather conditions, such as precipitation, the material of the Control stack, did not present a significant change in its expansive behavior. Thus, the monitoring period ended with 5.69% expansion, a value higher than that established by the standard.

3.4 Mechanical behavior in the hydrated carbonated slag (HCS) and control slag (CS)

3.4.1 Granulometry test

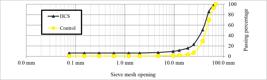

The particle size distribution of the studied slags was performed in accordance with the specifications of ASTM D5519-15. For the material to be used as railway ballast, it must have a particle size greater than 12.7 mm. Figure 9 presents the granulometric curves of HCS and Control materials, respectively. Table 1 presents the main characteristics of the HCS and Control aggregates.

3.4.2 Los angeles abrasion test

The results of the Los Angeles abrasion tests show that all material studied is suitable for this purpose to be used as rail ballast. Abrasiveness is another test that is directly associated with ballast life. Table 2 presents the results.

The maximum abrasion limit Los Angeles recommended by Arema (2002) for BOF steel slag is 30%. Thus, it can be observed that the treatment in the HCS pile led to the material getting less abrasiveness than the Control battery, and therefore a longer service life. The best result presented in the HCS cell was provided through the stabilization process imposed on the material by the timed hydration (Fernandes, 2010FERNANDES, D. P. Estudo de estabilização química, geo-mecânica e ambiental das escórias de aciaria LD para fins de aplicação como material de lastro ferroviário em vias sinalizadas . 2010. 142 f. Dissertação (Mestrado em Geotecnia) - Núcleo de Geotecnia, Escola de Minas, Universidade Federal de Ouro Preto, Ouro Preto, 2010.).

3.4.3 Shock resistance test

The results of the shock resistance tests for the material researched showed that all material presented shock resistance in accordance with the limits established by Arema (2002) of 20%. Table 3 presents the results of the assay.

The HCS stack had an adequate performance in this test, with values close to half of the maximum allowed, while the control pile obtained a slightly worse performance, since the value obtained, is near the limit set by the standard. Similarly, for the Los Angeles Abrasion Test, the better result presented in the HCS stack was provided by the treatment process on the unstable oxides present in the material. The compliance of this index with standard limits gives the rail ballast a longer service life with lower maintenance costs. Therefore, from the results achieved, it can be stated that the HCS sample will confer a longer ballast life and lower maintenance cost than the Control sample (Fernandes, 2010FERNANDES, D. P. Estudo de estabilização química, geo-mecânica e ambiental das escórias de aciaria LD para fins de aplicação como material de lastro ferroviário em vias sinalizadas . 2010. 142 f. Dissertação (Mestrado em Geotecnia) - Núcleo de Geotecnia, Escola de Minas, Universidade Federal de Ouro Preto, Ouro Preto, 2010.).

4. Conclusion

This research is relevant in the national context, since the Brazilian steel industry still employs a steel slag treatment methodology that stacks the material without a defined geometric configuration and uses water without time control to gradually hydrate the unstable oxides. Based on this article, it will be possible to change the paradigm in the chemical stabilization of steel slag and thus optimize the time required for treatment.

The reuse and recycling of steel co-products for engineering applications provides several advantages within the context of sustainability, such as the reduction of degraded areas by using natural aggregates (gravel). In the specific case of BOF slag, its reuse decreases the volume of material that is destined for the industrial landfill, minimizes environmental damage and reduces the amount of gravel that is mined in quarries, as well as generating financial resources for the steelmaker, since it is a cheaper product for the construction or maintenance of the railway.

Analyzing the results achieved in the physical characterization assays of the steel slag samples, there is clearly a difference in quality between the material of the HCS pile and the material of the Control pile. The HCS stack obtained better performance in all physical tests performed, highlighting Los Angeles Abrasion and Treton Tests. In this context, smaller Los Angeles Abrasion and Treton results mean that the aggregate wears out less over time, since the tests simulate friction and shock situations, therefore, from the results presented for the HCS and Control stack, it is possible to state that the ballast formed by the HCS stack would have a much longer life than if the ballast from the Control stack is applied. About the granulometry test, it is possible to notice that the HCS pile aggregate obtained a higher percentage of powdery materials. This is due to the stabilization process applied to the pile that hydrated and carbonated the aggregate causing a more controlled volumetric expansion, but that generated fragments. These fragments will be removed from the samples when they pass again through the appropriate granulometric classification for railway ballast.

In relation to the chemical characterization of aggregates, the free lime content test showed that with hydration and carbonation, the behavior of the curve for the HCS aggregate assumes a downward pattern, which after about 100 days reaches less than 2% of free lime content. This result is quite significant because it shows a paradigm shift in relation to the method applied to steel slag, allowing stabilization in terms of free lime in less than 4 months, when the technical literature recommends at least 6 months to 1 year. Thus, it should be emphasized that the scientific implication of the experimental work developed in this research was a method for stabilizing BOF steel slag that obtains expressive results in terms of reducing the free lime content in considerably less time than the methods applied in Brazilian steel industries.

About the expansibility evaluation by the adapted method of PTM-130, it is possible to verify that the curves referring to the HCS and Control aggregates obtained descending behaviors throughout the monitoring period. However, it is perceptible that the HCS stack curve had a much steeper decline in relation to the Control stack, reaching less than 2% of expansion with about 60 days. In the same period analyzed, the Control Cell still had around 6%, which would make it impossible to use it for paving purposes.

For all the above, it is concluded that the proposal to develop a method to stabilize the BOF steel slag, by timed hydration and carbonation, was very efficient and proved to be possible to stabilize the steel aggregate for use as railroad ballast in a period of less than 120 days.

References

- AMERICAN SOCIETY FOR TESTING AND MATERIAL. ASTM C131 / C131M-14: Standard test method for resistance to degradation of small-size coarse aggregate by abrasion and impact in the Los Angeles Machine. West Conshohocken, PA: ASTM International, 2006.

- AMERICAN SOCIETY FOR TESTING AND MATERIAL. ASTM D5519-15: Standard test methods for particle size analysis of natural and man-made riprap materials. West Conshohocken, PA: ASTM International , 2015.

- ÂNGULO, S. C.; ZORDAN, S. E.; JONH, V. M. Desenvolvimento sustentável e a reciclagem de resíduos na construção civil. In: SEMINÁRIO DESENVOLVIMENTO SUSTENTÁVEL E A RECICLAGEM NA CONSTRUÇÃO CIVIL, 4., 2001, São Paulo. Anais […] São Paulo: IBRACON - CT206, 2001.

- AREMA. Manual for Railway Engineering Lanham: American Railway Engineering and Maintenance Association - AREMA, 2001. v. I-IV.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ABNT NBR 7227 : Cimento Portland: determinação de óxido de cálcio livre pelo etileno glicol: método de ensaio. Rio de Janeiro: ABNT, 1989.

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. ABNT NBR 8938 : Lastro padrão: determinação da resistência ao choque: método de ensaio. Rio de Janeiro: ABNT , 1985.

- BRITISH STANDARDS INSTITUTION. BS EN 1744-1 : Tests for chemical properties of aggregates - part 1: chemical analysis. Brussels: BSI, 1998. 66 p.

- DEPARTAMENTO DE ESTRADAS DE RODAGEM DE MINAS GERAIS. Método de ensaio para avaliação do potencial de expansão da escória de aciaria : adaptação do PTM-130, DMA-1/DER-MG/92 PTM 130/78. [S. l.]: 1992.

- DEPARTAMENTO NACIONAL DE ESTRADAS DE RODAGEM. DNER-EM 262/94 : Escórias de aciaria para pavimentos rodoviários. Rio de Janeiro: DNER, 1994. 4 p.

- DIPPENAAR, R. Industrial uses of slag (the use and re-use of iron and steelmaking slags). Ironmaking & Steelmaking , v. 32, n.1, p. 35-46, 2005.

- EMERY, J. J. Utilisation des scories d’aciérie dans la construction des autoroutes canadiennes. Revue de Métallurgie , Paris, v. 75, n.5, p. 303-310, mai 1978.

- FERNANDES, D. P. Metodologia para estabilização química do agregado siderúrgico para aplicação como lastro ferroviário 2016. 224 f. Tese (Doutorado em Geotecnia) - Núcleo de Geotecnia, Escola de Minas, Universidade Federal de Ouro Preto, Ouro Preto, 2016.

- FERNANDES, D. P. Estudo de estabilização química, geo-mecânica e ambiental das escórias de aciaria LD para fins de aplicação como material de lastro ferroviário em vias sinalizadas 2010. 142 f. Dissertação (Mestrado em Geotecnia) - Núcleo de Geotecnia, Escola de Minas, Universidade Federal de Ouro Preto, Ouro Preto, 2010.

- GAO, J.; SHA, A.; WANG, Z.; TONG, Z.; LIU, Z. Utilization of steel slag as aggregate in asphalt mixtures for microwave deicing. Journal of Cleaner Production , v. 152, p. 429-442, May 2017.

- GEYER, R. M. T. Estudo sobre a potencialidade de uso das escórias de aciaria como adição ao concreto 2001. 145 f. Tese (Doutorado em Engenharia) - Escola de Engenharia, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2001.

- GUMIERE, A. G. Estudo da viabilidade técnica da utilização de escórias de aciaria do processo LD como adição em cimentos 2002. 219 f. Tese (Doutorado em Engenharia) - Escola de Engenharia, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2002.

- GUTT, W. Agregates from waste materials. Chemistry and Industry , V. 49, p. 439-447, Jun. 1972.

- HIRANO, Y. How to expand the market for BOF slags in Japan. In: COMMITTEE ON ENVIRONMENTAL AFFAIR. Utilization of blast furnace and bof slag Brussels, Belgium: International Iron and Steel Institute, 1984. section A2, p. 32- 43.

- HOLLIDAY, K. A. Steel slag: the high performance industrial aggregate. Steel World , v. 2, n. 1, p.11-14, 1997.

- JAPANESE INDUSTTRIAL STANDARD. JIS A 5015 : Steel slag for road construction. [S. l.]: JIS, 1992, 48p.

- KOH, T.; MOON, S.-W.; JUNG, H.; JEONG, Y.; PYO, S. A feasibility study on the application of basic oxygen furnace (BOF) steel slag for railway ballast material. Sustainability , v. 10, n. 2, 284, 2018.

- MASUERO A. B. Estabilização das escórias de aciaria elétrica com vistas a sua utilização como substituição ao cimento 2001. 264 f. Tese (Doutorado em Engenharia) - Escola de Engenharia, Universidade Federal do Rio Grande do Sul, Porto Alegre, 2001.

- MONTGOMERY, D. G.; WANG, G. Instant-chilled steel slag aggregate in concrete: strength related properties. Cement and Concrete Research , v. 21, n. 6, p. 1083-91, 1991b.

- MOTZ, H.; GEISELER, J. Products of steel slags an opportunity to save natural resources. Waste Management , v. 21, n. 3, p. 285-293, Jun. 2001.

- MOTZ, H.; GEISELER, J. The steel slags: properties, properties and quality assurance. In: EUROPEAN SLAG CONFERENCE, 1998, Marseilles, France. Proceedings […] . [S. l.: s. n.], 1998. p. 149-168. (Iron and Steel Slags - Properties and utilization).

- PENNSYLVANIA DEPARTMENT OF TRANSPORTATION. PTM 130 method : test method for evaluating the potential for steel slag expansion. Pennsylvania, USA: PennDOT: Materials, Testing and Research Laboratory, 1982.

- SANTOS, R. M.; LING, D.; SARVARAMINI, A.; GUO, M.; ELSEN, J.; LARACHI, F.; BEAUDOIN, G.; BLANPAIN, B.; VAN GERVEN, T. Stabilization of basic oxygen furnace slag by hot-stage carbonation treatment. Chemical Engineering Journal , v. 203, p. 239-250, Sep. 2012.

- TOPKAYA, Y.; SEVINC, N.; GUNAYDIN, A. Slag treatment at Kardemir integrated iron and steel works. International Journal of Mineral Processing , v. 74, n. 1-4, p. 31-39, Nov. 2004.

- WANG, G.; WANG, Y.; GAO, Z. Use of steel slag as a granular material: volume expansion prediction and usability criteria. Journal of Hazardous Materials , v. 184, n.1-3, p. 555-560, Dec. 2010.

Publication Dates

-

Publication in this collection

30 Sept 2020 -

Date of issue

Oct-Dec 2020

History

-

Received

08 Mar 2020 -

Accepted

20 July 2020