Abstract

Kuini powders were obtained through spray-drying, freeze-drying, vacuum oven drying and convection oven drying. Colour, water activity (Aw), moisture content, hygroscopicity, wettability, flowability, degree of caking, water solubility index (WSI), total colour change, total phenolic content and total carotenoid content of Kuini powders were determined and compared. Convection oven drying resulted in the highest yield (46.97%), moisture content (4.91%), Aw (0.55) and WSI (74.33%) among all the drying methods. However, convection oven-dried Kuini powder had the lowest hygroscopicity and wettability, which were 18.66% and 12.04 s, respectively. Spray drying resulted in poor hygroscopicity (22.41%), degree of caking (22.16%), wettability (275s), WSI (45.67%) and higher colour change (59.81). Least total colour change (19.05) and higher yellowness (57.31) were observed in freeze-drying. In addition, freeze-dried Kuini powder had the highest total phenolic content (24.76 mg/100 g) and total carotenoid content (1.61 mg/100 g). Drying temperature had a negative and significant correlation with the retention of color pigments and antioxidant content. The physicochemical properties and antioxidant content of freeze-dried Kuini powder were preferred over spray-dried, vacuum oven-dried and convection oven-dried powders. Hence, freeze-drying offers potential application in the food products.

Keywords:

Mangifera odorata; Convection oven drying; Freeze-drying; Vacuum oven drying; Spray-drying; Phenolic content; Carotenoid content

Resumo

Secagem por pulverização, secagem por congelamento, secagem em forno a vácuo e secagem em forno de convecção foram utilizados para obtenção de Kuini em pó. Cor, atividade de água, teor de umidade, higroscopicidade, molhabilidade, fluidez, grau de aglomeração, índice de solubilidade em água, mudança de cor total, teor de fenólico total e teor de carotenoide total dos produtos de Kuini em pó foram determinados e comparados. A secagem em estufa de convecção resultou em maior rendimento (46,97%), teor de umidade (4,91%), atividade de água (0,55) e índice de solubilidade em água (74,33%), entre todos os métodos de secagem. No entanto, o produto seco em forno de convecção apresentou a menor higroscopicidade e molhabilidade, que foram de 18,66% e 12,04 s, respectivamente. A secagem por spray resultou em baixa higroscopicidade (22,41%), grau de aglomeração (22,16%), molhabilidade (275s), índice de solubilidade em água (45,67%) e grande mudança de cor (59,81). A menor mudança total de cor (19,05) e o maior amarelecimento (57,31) foram observados na liofilização. Além disso, o produto liofilizado apresentou o maior teor de fenólicos totais (24,76 mg/100 g) e de carotenoides totais (1,61 mg/100 g). A temperatura de secagem teve correlação negativa e significativa com a retenção de pigmentos e o teor de antioxidantes. As propriedades físico-químicas e o conteúdo antioxidante do Kuini liofilizado o tornam preferível em relação aos pós secos por pulverização, secos em estufa a vácuo e secos em estufa de convecção. Portanto, a liofilização oferece uma aplicação potencial em produtos alimentícios.

Palavras-chave:

Kuini; Secagem em forno de convecção; Liofilização; Secagem em forno a vácuo; Secagem por spray; Conteúdo fenólico; Conteúdo de carotenoides

1 Introduction

Fresh fruits are highly perishable and have short shelf life. In order to make fruits available all year round, preservation is needed. In convection oven drying, heat is transferred from the surface to the interior of the material and moisture is removed through evaporation (Brennan & Grandison, 2006Brennan, J. G., & Grandison, A. S. (2006). Food processing handbook (pp. 105-110). Germany: Wiley.). Whereas vacuum oven drying removes moisture under low pressure hence causes low shrinkage rate as well as colour degradation (Jaya & Das, 2003Jaya, S., & Das, H. (2003). A vacuum drying model for mango pulp. Drying Technology: An International Journal, 21(7), 1215-1234. http://dx.doi.org/10.1081/DRT-120023177

http://dx.doi.org/10.1081/DRT-120023177...

). Spray-drying involves the atomization of liquid feed and hot stream of gas which turns the fine particles into powder within seconds (Chew & Tan, 2019Chew, S., & Tan, C. (2019). PUI; CHONG, P.; GUNASEKARAN, B.; NYAM, K. Encapsulation technologies: A tool for functional foods development. International Journal of Innovative Technology and Exploring Engineering, 8(5S), 154-160.). Conversion of tropical fruit powder from puree and juice were reported for papaya, ‘Terung Asam’, and ‘Cempedak’ (Chang et al., 2020aChang, L. S., Tan, Y. L., & Pui, L. P. (2020a). Production of spray-dried enzyme-liquefied papaya (Carica papaya L.) powder. Brazilian Journal of Food Technology, 23, e2019181. http://dx.doi.org/10.1590/1981-6723.18119

http://dx.doi.org/10.1590/1981-6723.1811...

, 2020bChang, L. S., Yong, S. M. E., & Pui, L. P. (2020b). Production of Spray-dried “Terung Asam” (Solanum lasiocarpum Dunal) Powder. Walailak Journal of Science and Technology. In press.; Pui et al., 2020aPui, L. P., Karim, R., Yusof, Y. A., Wong, C. W., & Ghazali, H. M. (2020a). Optimization of spray-drying parameters for the production of ‘Cempedak’ (Artocarpus integer) fruit powder. Journal of Food Measurement and Characterization, 14(6), 3238-3249. http://dx.doi.org/10.1007/s11694-020-00565-3

http://dx.doi.org/10.1007/s11694-020-005...

, 2020bPui, L. P., Karim, R., Yusof, Y. A., Wong, C. W., & Ghazali, H. M. (2020b). Anti-caking agent effects on the properties of spray-dried ‘cempedak’ fruit powder. Journal of Tropical Agricultural Science. In press.). On the other hand, freeze-drying results in less damage to the initial properties of fruits as it includes crystallization and sublimation at reduced pressure (Caparino et al., 2012Caparino, O., Tang, J., Nindo, C., Sablani, S., Powers, J., & Fellman, J. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. Journal of Food Engineering, 111(1), 135-148. http://dx.doi.org/10.1016/j.jfoodeng.2012.01.010

http://dx.doi.org/10.1016/j.jfoodeng.201...

; Ceballos et al., 2012Ceballos, A. M., Giraldo, G. I., & Orrego, C. E. (2012). Effect of freezing rate on quality parameters of freeze dried soursop fruit pulp. Journal of Food Engineering, 111(2), 360-365. http://dx.doi.org/10.1016/j.jfoodeng.2012.02.010

http://dx.doi.org/10.1016/j.jfoodeng.201...

).

Kuini (Mangifera odorata Griff.) is an underutilised wild mango species, originated from Philipines and cultivated in Malaysia, Singapore, Thailand and Indonesia (Lim, 2012Lim, T. K. (Ed.). (2012). Edible medicinal and non-medicinal plants. Dordrecht: Springer.). It is known for its distinctive fragrantly smell. Kuini is round in shape, has green skin, and vivid yellow orange pulp that is juicy when ripe. The volatile components responsible for the aroma are oxygenated monoterpenes and esters (Wong & Ong, 1993Wong, K., & Ong, C. (1993). Volatile components of the fruits of bachang (Mangifera foetida Lour.) and Kuini (Mangifera odorata Griff.). Flavour and Fragrance Journal, 8(3), 147-151. http://dx.doi.org/10.1002/ffj.2730080305

http://dx.doi.org/10.1002/ffj.2730080305...

). It is commonly made into sambal, juice, jam, mango pickles and salads by women-folk (Brooke & Lau, 2013Brooke, P., & Lau, C. (2013). Nutritional value and economic potential of underutilised Mangifera species in Bungai Area, Sarawak, Malaysia. Acta Horticulturae, 979(8), 107-115. http://dx.doi.org/10.17660/ActaHortic.2013.979.8

http://dx.doi.org/10.17660/ActaHortic.20...

). Studies had proven that Kuini has reputable antioxidant properties, due to the presence of phenolic compounds (257.17 mg/100 g) and carotenoids (3.95 mg/100 g) (Khoo et al., 2008Khoo, H. E., Ismail, A., Mohd-Esa, N., & Idris, S. (2008). Carotenoid content of underutilized tropical fruits. Plant Foods for Human Nutrition, 63(4), 170-175. PMid:18810641. http://dx.doi.org/10.1007/s11130-008-0090-z

http://dx.doi.org/10.1007/s11130-008-009...

). Mirfat et al. (2015)Mirfat, A., Razali, M., Salma, I., & Kalsum, H. (2015). Antioxidant and nutritional values of selected under-utilised Mangifera species in Malaysia. Indian Journal of Plant Genetic Resources, 28(1), 72. http://dx.doi.org/10.5958/0976-1926.2015.00010.8

http://dx.doi.org/10.5958/0976-1926.2015...

found that Kuini has higher protein content, calcium when compared to other mango species. Sulaiman & Ooi (2012)Sulaiman, S. F., & Ooi, K. L. (2012). Polyphenolics, vitamin C, and antioxidant activities of aqueous extracts from mature-green and ripe fruit fleshes of Mangifera sp. Journal of Agricultural and Food Chemistry, 60(47), 11832. PMid:23136968. http://dx.doi.org/10.1021/jf303736h

http://dx.doi.org/10.1021/jf303736h...

reported that Kuini has Mangiferin, gallic acid, vanillic acid as the phenolic compounds. In our previous study, the storage stability spray-drying of Kuini powder in different packaging were investigated (Loo and Pui, 2020Loo, Y. Y., & Pui, L. P. (2020). Storage stability of kuini (Mangifera odorata) powder in aluminum laminated polyethylene and polyethylene terephthalate. The Malaysian Journal of Analytical Sciences, 24(5), 657-669. Retrieved in 2020, April 17, from https://mjas.analis.com.my/mjas/v24_n5/pdf/Loo_24_5_4.pdf

https://mjas.analis.com.my/mjas/v24_n5/p...

).

However, Kuini powder is not available in the market and the information on the production of Kuini powder is scarce. In addition, although there are many literatures on the drying of fruit juice and puree, the comparison on the different drying methods is minimal. Senphan et al. (2019)Senphan, T., Yakong, N., Aurtae, K., Songchanthuek, S., Choommongkol, V., Fuangpaiboon, N., Phing, P. L., & Yarnpakdee, S. (2019). Comparative studies on chemical composition and antioxidant activity of corn silk from two varieties of sweet corn and purple waxy corn as influenced by drying methods. Food and Applied Bioscience Journal, 7(3), 64-80. Retrieved in 2020, April 17, from https://li01.tci-thaijo.org/index.php/fabjournal/article/view/225020

https://li01.tci-thaijo.org/index.php/fa...

compared the effect of freeze-drying and hot air drying on corn silk powder properties, while Gopinathan et al. (2020)Gopinathan, M., Yusof, Y. A., & Pui, L. P. (2020). Effects of different drying methods on the physicochemical and antioxidant content of ‘cempedak’ (Artocarpus integer L.) powder. Journal of Food Processing and Preservation, 44(12), (in press) http://dx.doi.org/10.1111/jfpp.14966

http://dx.doi.org/10.1111/jfpp.14966...

determined the effects of spray-drying, freeze-drying, convection oven drying, and vacuum-drying on ‘cempedak’ powder properties. Therefore, this research aimed to determine and compare the physicochemical properties and antioxidant content of convection dried, vacuum oven-dried, spray-dried and freeze-dried powder. Additionally, this research also aimed to identify the suitable drying method that is commonly applied in the industries to produce Kuini powder with ideal powder properties, nutritional value and production cost. As the characteristic powder may be different under the drying methods, the selection of method used in the industry may need to compromise the attributes with regards to the purpose of production. For instance, the nutritive value of powder used to food ingredient will be less important, as compared to physical stability.

2 Materials and methods

2.1 Sample preparation

The fresh Kuini fruits were purchased from Pasar Pagi Pekan Semenyih and kept in the refrigerator in Food Science Lab of University College Sedaya International (UCSI). The Kuini fruits were washed with tap water to remove dirt and then skin was peeled. The pulps were obtained with the seeds removed. The pulps were cut in a smaller cube were placed in a commercial blender and homogenised. The puree was added with 50% (w/w) maltodextrin (DE=10, Bronson and Jacobs, Australia) as a fixed variable as the puree was highly viscous and sticky. Indeed, a higher carrier is needed for puree that has a higher solid content to ensure that powder produced is not sticky.

2.2 Drying methods

The prepared mixture was dried using four methods, as described below.

-

1

Convection Oven Drying: The mixture was poured into the steel tray with aluminium foil and dried in a convection oven (UNB500, Memmert, Germany) at 45 °C for 3 days. The process ended when consistent dry weight was obtained;

-

2

Vacuum Oven Drying: Approximately 1.5 cm thick layer of the prepared mixture were poured on a stainless-steel tray and inserted into the vacuum oven (VD05, Binder, Germany) which operated at 70 °C and 1 bar for 24 h. The process ended when consistent dry weight was obtained;

-

3

Spray-drying: Prior to spray-drying, the fruit puree was homogenized, and bigger solids removed using a filter cloth. The mixture was added with distilled water in a ratio of 1:4. The spray drying of Kuini mixture was performed by a spray dryer (SD05, Labplant, UK) at 170 °C with the feed flow rate of 10 mL/min. The spray-dried powder were collected at the collection vessel once the spray drying mixed were all channeled into the spray dryer and sprayed with distilled water for 3 min;

-

4

Freeze-drying: Prior to freeze-drying, the mixture was frozen overnight at -80 °C and the freeze dryer (Martin Christ, Germany) was warmed up for 30 min. The main drying process took 48 h at -20 °C and continued with the phase final drying for 2 h. The process ended all the mixture turned into dry flakes.

The dried product was ground into fine powder with a grinder and sieved, except spray-dried powder. The powder obtained was vacuum packed in a polyethylene bag and kept in freezer at -20°C for further analysis.

2.3 Process yield

The process yield of the drying methods was calculated using the Equation 1:

2.4 Water activity and moisture content

The water activity (Aw) of the powders were measured using AquaLab Pre Water Activity Meter (Decagon Devices, US) at room temperature (25±2°C). The moisture content of the powder was determined in accordance to Quek et al. (2007)Quek, S. Y., Chok, N. K., & Swedlund, P. (2007). The physicochemical properties of spray-dried watermelon powders. Chemical Engineering and Processing: Process Intensification, 46(5), 386-392. http://dx.doi.org/10.1016/j.cep.2006.06.020

http://dx.doi.org/10.1016/j.cep.2006.06....

with modifications. The powder was dried in a preheated convection oven (UNB500, Memmert, Germany) at 105 °C to a constant weight. The moisture content of the powders was calculated using Equation 2:

2.5 Hygroscopicity, degree of caking and flowability

The hygroscopicity measurement was modified from Cai & Corke (2000)Cai, Y. Z., & Corke, H. (2000). Production and properties of spray‐dried Amaranthus betacyanin pigments. Journal of Food Science, 65(7), 1248-1252. http://dx.doi.org/10.1111/j.1365-2621.2000.tb10273.x

http://dx.doi.org/10.1111/j.1365-2621.20...

. The powder was placed in a glass desiccator pre-filled with saturated ammonium sulphate (Qrec, New Zealand) solution to create the relative humidity of 81%. The samples were weighed after a week. The hygroscopicity was determined using Equation 3:

For degree of caking, 5 g of powder was sieved through a 30 mesh size sieve and remaining powder on the sieve was weighed (Goula & Adamopoulos, 2010Goula, A. M., & Adamopoulos, K. G. (2010). A new technique for spray drying orange juice concentrate. Innovative Food Science & Emerging Technologies, 11(2), 342-351. http://dx.doi.org/10.1016/j.ifset.2009.12.001

http://dx.doi.org/10.1016/j.ifset.2009.1...

). The degree of caking was calculated using Equation 4:

Flowability is determined in the angle of repose. The filter funnel was set at 2 cm above the base. Five grams of powder was poured from the top of the filter funnel. The height and diameter of the small mountain formed was measured (Guo et al., 2014Guo, Z., Chen, X., Liu, H., Guo, Q., Guo, X., & Lu, H. (2014). Theoretical and experimental investigation on angle of repose of biomass-coal blends. Fuel, 116, 131-139. http://dx.doi.org/10.1016/j.fuel.2013.07.098

http://dx.doi.org/10.1016/j.fuel.2013.07...

). The calculation was done according to Equation 5:

2.6 Wettability and water solubility index

The wettability was determined by measuring the time taken, in s, for 1 g of powder to get fully wet in 10 mL of distilled water. For water solubility index (WSI), 1 g of powder was poured into 10 mL of distilled water and incubated at 37 °C in a water bath with shaker (Memmert, Germany) for 30 min. The solution was centrifuged (Eppendorf, Germany) at 4,400 rpm for 10 min and the supernatant was dried in a convection oven (UNB500, Memmert, Germany) at 105 °C for 5 h. The calculation was done using Equation 6 (Dailami, 2009Dailami, M. T. (2009). Production of dragon fruit powder using spray drying method (Doctoral dissertation). Universiti Malaysia Pahang, Malaysia.):

2.7 Colour, reconstitution of powder and total colour change

The colour analysis was carried out using HunterLab ColorFlex EZ Colourimeter (Hunter Associates Laboratory, Inc. US) and expressed in L*, a* and b* values (Pua et al., 2010Pua, C. K., Hamid, N. S. A., Tan, C. P., Mirhosseini, H., Rahman, R. B. A., & Rusul, G. (2010). Optimization of drum drying processing parameters for production of jackfruit (Artocarpus heterophyllus) powder using response surface methodology. Food Science and Technology, 43(2), 343-349. http://dx.doi.org/10.1016/j.lwt.2009.08.011

http://dx.doi.org/10.1016/j.lwt.2009.08....

). The reconstitution of powder was carried out according to Youssefi et al. (2009)Youssefi, S., Emam-Djomeh, Z., & Mousavi, S. M. (2009). Comparison of artificial neural network (ANN) and response surface methodology (RSM) in the prediction of quality parameters of spray-dried pomegranate juice. Drying Technology, 27(7-8), 910-917. http://dx.doi.org/10.1080/07373930902988247

http://dx.doi.org/10.1080/07373930902988...

with modifications. The powder was rehydrated with distilled water to obtain the total solid content of the fresh juice (10.4 °Brix) (Milwaukee MA871 Digital Sugar Refractometer). The total colour change was obtained through the colour analysis of reconstituted powder and fresh juice and determined using Equation 7 (Kha et al., 2010Kha, T. C., Nguyen, M. H., & Roach, P. D. (2010). Effects of spray drying conditions on the physicochemical and antioxidant properties of the gac (Momordica cochinchinensis) fruit aril powder. Journal of Food Engineering, 98(3), 385-392. http://dx.doi.org/10.1016/j.jfoodeng.2010.01.016

http://dx.doi.org/10.1016/j.jfoodeng.201...

):

where , and were related to the lightness, redness and yellowness of the fresh juice, and , and were associated to the lightness, redness and yellowness of the reconstituted powders.

2.8 Total phenolic content

For the extraction process, 0.2 g of powder was dissolved in 5 mL of distilled water in a conical flask. The solution was stirred and added with 5 mL of methanol (≥99.8, Fisher Scientific, US). The conical flask was shaken for an hour and centrifuged (Eppendorf, Germany) at 4,400 rpm for 10 min. The determination of total phenolic content (TPC) was done according to Lim et al. (2007)Lim, Y. Y., Lim, T. T., & Tee, J. J. (2007). Antioxidant properties of several tropical fruits: A comparative study. Food Chemistry, 103(3), 1003-1008. http://dx.doi.org/10.1016/j.foodchem.2006.08.038

http://dx.doi.org/10.1016/j.foodchem.200...

with modifications. Extracts of 300 µL was transferred into test tubes wrapped with aluminium foil. Then, 1.5 mL of the Folin-Ciocalteu reagent (10 times diluted) (Merk KGaA, Germany) was added into the test tubes and followed by 1.2 mL of sodium carbonate 7.5% (w/v) (Sigma-Aldrich, US). The test tubes were left to stand in the dark for 30 min before measuring the absorbance (7500, Jenway, UK) at 765 nm. The TPC was expressed as gallic acid equivalent (GAE) in mg per 100 g of sample.

2.9 Total carotenoid content

The total carotenoid (TC) content was determined according to Scrob et al. (2014)Scrob, S., Muste, S., Haș, I., Mureșan, C., Socaci, S., & Fărcaș, A. (2014). Total content of carotenoids in corn landraces and their potential health applications. Bulletin UASVM Food Science and Technology, 71(2), 96-100. http://dx.doi.org/10.15835/buasvmcn-fst:10396

http://dx.doi.org/10.15835/buasvmcn-fst:...

with modifications. Three grams of powder were dissolved in 10 mL of distilled water and incubated at 25 °C. After 30 min, 20 mL of cold acetone (≥ 99.8, Merk KGaA, Germany) was added and incubated at 25 °C for 15 min. The sample solution then underwent vacuum filtration. The filtrate and 50 mL of petroleum ether (35° to 60°) was poured in a separatory funnel. The top layer solution was filtered with 15 g of sodium sulfate anhydrous (Qrec, New Zealand) in the separatory funnel. The filtrate collected was evaporated (Rotavapor R-200, Buchi, Switzerland) at 25 °C. The dried extract was reconstituted with 1 mL of cold acetone and absorbance (7500, Jenway, UK) was determined at 450 nm. The TC content was expressed as mg per 100 g of sample.

2.10 Statistical analysis

The experiments were carried out nine times (n=9). One-way Analysis of Variance (ANOVA) test was performed for the analysis of data with the significance difference of p ≤ 0.05. All the data collected was interpreted using Minitab 17 and expressed in means and Standard Deviations (SD).

3 Results and discussion

3.1 Visual examination and process yield

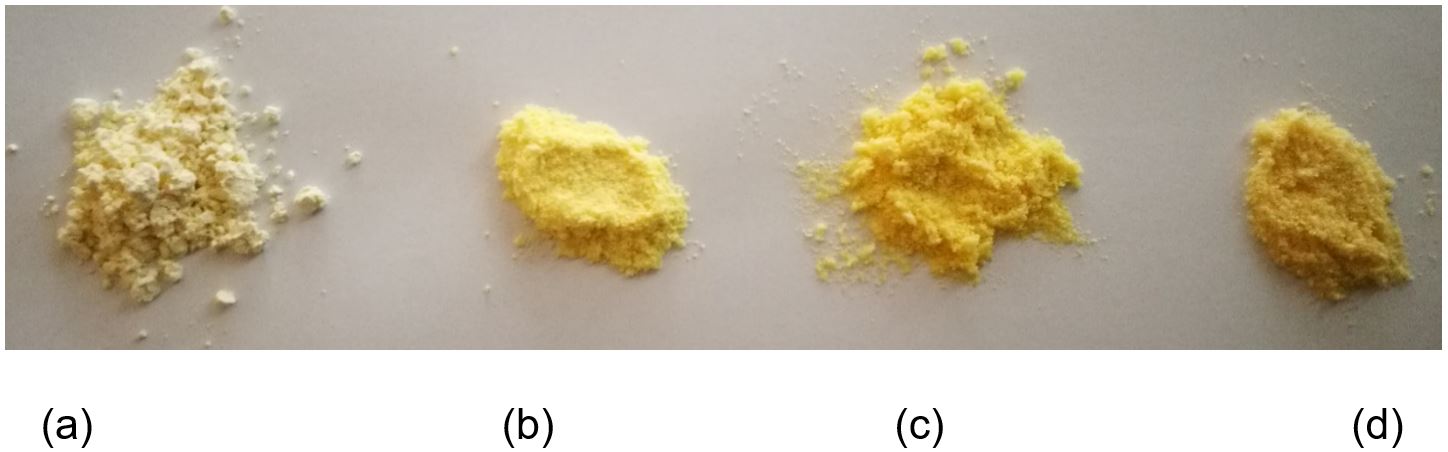

Visual examination could illustrate that the freeze-dried, vacuum oven-dried and convection oven-dried Kuini powder were bright yellow. On the other hand, the spray-dried Kuini powder was pale yellow (Figure1). Table 1 shows the yield of different drying methods.

Spray-dried (a), freeze-dried (b), vacuum oven-dried (c) and convection oven-dried (d) Kuini powders.

Process yield of spray-drying, freeze-drying, vacuum oven drying and convection oven drying of Kuini powders.

From Table 1, it is found that the powder yield was highest in convection oven drying (46.97%), followed by vacuum oven drying (37.61%), freeze-drying (35.98%) and spray-drying (14.39%). Convection and vacuum oven drying had higher yield as they did not undergo many steps during the drying as compared to freeze-drying and spray-drying. In addition, freeze-dried products were characterized by low apparent density and high porosity, which led to reduced yield (35.98%) (Argyropoulos et al., 2011Argyropoulos, D., Heindl, A., & Müller, J. (2011). Assessment of convection, hot-air combined with microwave-vacuum and freeze-drying methods for mushrooms with regard to product quality. International Journal of Food Science & Technology, 46(2), 333-342. http://dx.doi.org/10.1111/j.1365-2621.2010.02500.x

http://dx.doi.org/10.1111/j.1365-2621.20...

). The low yield of spray-drying is due to some amount of powder sticking to the drying chamber wall, which is stickier with the increase spray drying time, hence to be taken into consideration as the powder yield, as it has different characteristic as those collected in the collection vessel (Hui, 2008Hui, Y. H. (Ed.). (2008). Food drying science and technology: Microbiology, chemistry, applications. Lancaster: DEStech Publications.).

Apart from powder yield, physicochemical properties of powder are important, as it will influence the stability and overall acceptance of the powders produced. Table 2 shows the effect of drying methods on the physicochemical properties of Kuini powders.

Effect of drying methods on the physicochemical properties of Kuini powders obtained from different drying methods.

3.2 Water activity and moisture content

From Table 2, spray-dried powder had the lowest Aw (0.16) and moisture content (MC) (2.76%), followed by freeze-drying and vacuum oven drying produced powders. Convection oven-dried Kuini powder, on the other hand, had the highest Aw (0.55) and MC (4.91%). With the lowest Aw and MC, the spray-drying method is preferred, as it produces powder that is more stable microbiologically. This is due to its high drying temperature which led to high evaporation rate (Jittanit et al., 2010Jittanit, W., Att, S. N., & Techanuntachaikul, O. (2010). Study of spray drying of pineapple juice using maltodextrin as an adjunct. Warasan Khana Witthayasat Maha Witthayalai Chiang Mai, 37(3), 498-506. Retrieved in 2020, April 17, from https://pdfs.semanticscholar.org/f855/15fa942828e4ea27b91ec1b1c11ff2cf0530.pdf

https://pdfs.semanticscholar.org/f855/15...

). Whereas convection oven drying utilized low temperature which led to less moisture loss.

Food deterioration caused by microbial activity is inhibited below Aw of 0.6, whereas fungi and yeast are inhibited below 0.7 and 0.8, respectively (Gobbetti et al., 2010Gobbetti, M., Cagno, R. D., & De Angelis, M. (2010). Functional microorganisms for functional food quality. Critical Reviews in Food Science and Nutrition, 50(8), 716-727. PMid:20830633. http://dx.doi.org/10.1080/10408398.2010.499770

http://dx.doi.org/10.1080/10408398.2010....

). Dried food products with Aw between 0.2 and 0.4 are free from browning, hydrolitical reactions, liquid oxidation, auto-oxidation as well as enzymatic activity (Singh & Heldman, 2001Singh, R. P., & Heldman, D. R. (2001). Introduction to food engineering. San Diego: Academic Press.). Hence, all the Kuini powders produced are safe from microbial, physical and chemical degradation except from convection oven-dried powder (0.55), which is susceptible to chemical deterioration. The Aw of fruit powders ranged from 0.17 to 0.44, which indicated conformity to others’ research works (Dirim & Çaliskan, 2012Dirim, S. N., & Çaliskan, G. (2012). Determination of the effect of freeze drying process on the production of pumpkin (Cucurbita moschata) puree powder and the powder properties. Journal of Food, 37(4), 203-210. Retrieved in 2020, April 17, from https://dergipark.org.tr/en/pub/gida/issue/6933/92554

https://dergipark.org.tr/en/pub/gida/iss...

; Jaya & Das, 2009Jaya, S., & Das, H. (2009). Glass transition and sticky point temperatures and stability/mobility diagram of fruit powders. Food and Bioprocess Technology, 2(1), 89-95. http://dx.doi.org/10.1007/s11947-007-0047-5

http://dx.doi.org/10.1007/s11947-007-004...

).

All Kuini powders produced in current study are microbiologically safe as evidenced by the moisture content below 5% (Wong et al., 2015Wong, C. W., Pui, L. P., & Ng, J. M. L. (2015). Production of spray-dried sarawak pineapple (Ananas comosus) powder from enzyme liquefied puree. International Food Research Journal, 22(4), 1631-1636. Retrieved in 2020, April 17, from http://www.ifrj.upm.edu.my/22%20(04)%202015/(44).pdf

http://www.ifrj.upm.edu.my/22%20(04)%202...

). Previous studies revealed that the moisture content of fruit powders was between 1.49% and 4.30% and similar readings were obtained (Agustini, 2018Agustini, S. (2018). The characterization of mango (Mangifera indica L) powder of various drying temperature. Journal of Physics: Conference Series, 1095(1), 12035. http://dx.doi.org/10.1088/1742-6596/1095/1/012035

http://dx.doi.org/10.1088/1742-6596/1095...

; Caparino et al., 2012Caparino, O., Tang, J., Nindo, C., Sablani, S., Powers, J., & Fellman, J. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. Journal of Food Engineering, 111(1), 135-148. http://dx.doi.org/10.1016/j.jfoodeng.2012.01.010

http://dx.doi.org/10.1016/j.jfoodeng.201...

; Quek et al., 2007Quek, S. Y., Chok, N. K., & Swedlund, P. (2007). The physicochemical properties of spray-dried watermelon powders. Chemical Engineering and Processing: Process Intensification, 46(5), 386-392. http://dx.doi.org/10.1016/j.cep.2006.06.020

http://dx.doi.org/10.1016/j.cep.2006.06....

).

3.3 Hygroscopicity, flowability and degree of caking

Convection oven-dried powder had the lowest hygroscopicity (18.66%) which is the most desirable. The low processing temperature in convection oven drying resulted in the highest moisture content thus reducing its capability to absorb moisture from surrounding (Tonon et al., 2008Tonon, R. V., Brabet, C., & Hubinger, M. D. (2008). Influence of process conditions on the physicochemical properties of açai (Euterpe oleraceae Mart.) powder produced by spray drying. Journal of Food Engineering, 88(3), 411-418. http://dx.doi.org/10.1016/j.jfoodeng.2008.02.029

http://dx.doi.org/10.1016/j.jfoodeng.200...

). While the hygroscopicity of freeze-dried, vacuum oven-dried and convection oven-dried powder had no significant difference, with the range of 18.66% to 19.89%. Highest hygroscopicity was observed in spray-dried powder due to its low moisture content which increased the water concentration gradient between the product and surrounding air. Thus, it has higher capacity to absorb moisture from environment (Sarabandi et al., 2014Sarabandi, K., Peighambardoust, S. H., & Shirmohammadi, M. (2014). Physical properties of spray dried grape syrup as affected by drying temperature and drying aids. International Journal of Agriculture and Crop Sciences, 7(12), 928-934. Retrieved in 2020, April 17, from https://pdfs.semanticscholar.org/7912/3ad58df9435ce5ae8bd14728ab5fd281b2f4.pdf

https://pdfs.semanticscholar.org/7912/3a...

). In addition, the fine particle size of spray-dried powder has large contact surface which ease water absorption (Ribeiro et al., 2016Ribeiro, L., Costa, J., & Afonso, M. (2016). Hygroscopic behavior of lyophilized acerola pulp powder. Brazilian Journal of Agricultural and Environmental Engineering, 20(3), 269-274. http://dx.doi.org/10.1590/1807-1929/agriambi.v20n3p269-274

http://dx.doi.org/10.1590/1807-1929/agri...

).

All Kuini powders were hygroscopic as the hygroscopicity falls within 15.1% and 24.9% (Schuck et al., 2012Schuck, P., Dolivet, A., & Jeantet, R. (2012). Analytical methods for food and dairy powders. West Sussex: Wiley. http://dx.doi.org/10.1002/9781118307397

http://dx.doi.org/10.1002/9781118307397...

). Kuini is rich in low molecular weight sugars and organic acids which led to the hygroscopic nature. Hence, it is suggested that the carrier agent, maltodextrin can be replaced with tapioca starch (Tonon et al., 2009Tonon, R. V., Brabet, C., Pallet, D., Brat, P., & Hubinger, M. D. (2009). Physicochemical and morphological characterisation of açai (Euterpe oleraceae Mart.) powder produced with different carrier agents. International Journal of Food Science & Technology, 44(10), 1950-1958. http://dx.doi.org/10.1111/j.1365-2621.2009.02012.x

http://dx.doi.org/10.1111/j.1365-2621.20...

). The hygroscopicity of spray-dried fruit powders ranged from 3.28% to 34.72%, which shows agreement with present study (22.41%) (Costa et al., 2014Costa, J. D. P. D., Rocha, É. M. D. F. F., & Costa, J. M. C. D. (2014). Study of the physicochemical characteristics of soursop powder obtained by spray-drying. Food Science and Technology, 34(4), 663-666. http://dx.doi.org/10.1590/1678-457X.6380

http://dx.doi.org/10.1590/1678-457X.6380...

; Moreira et al., 2009Moreira, G. E. G., Costa, M. G. M., Souza, A. C. R., Brito, E. S., Meideros, M. F. D., & Azeredo, H. M. C. (2009). Physical properties of spray dried acerola pomace extract as affected by temperature and drying aids. Food Science and Technology, 42(2), 642-645. http://dx.doi.org/10.1016/j.lwt.2008.07.008

http://dx.doi.org/10.1016/j.lwt.2008.07....

; Santhalakshmy et al., 2015Santhalakshmy, S., Don Bosco, S. J., Francis, S., & Sabeena, M. (2015). Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technology, 274, 37-43. http://dx.doi.org/10.1016/j.powtec.2015.01.016

http://dx.doi.org/10.1016/j.powtec.2015....

). Furthermore, the hygroscopicity of the freeze-dried Kuini powder (19.89%) is similar to the findings of the Carlos et al. (2005)Carlos, L. A., Resende, J. V., & Vidal, J. C. (2005). Hygroscopicity reduction of post-lyophilized by inducing crystallization in model solutions constituents of fruit sugars. Brazilian Journal of Food Technology, 8(2), 163-173. http://dx.doi.org/10.1590/1807-1929/agriambi.v20n3p269-274

https://doi.org/10.1590/1807-1929/agriam...

and Caparino et al. (2012)Caparino, O., Tang, J., Nindo, C., Sablani, S., Powers, J., & Fellman, J. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. Journal of Food Engineering, 111(1), 135-148. http://dx.doi.org/10.1016/j.jfoodeng.2012.01.010

http://dx.doi.org/10.1016/j.jfoodeng.201...

(18%).

In terms of degree of caking, it is found that vacuum oven-dried powder was the lowest (6.60%), followed by convection oven-dried powder (12.57%), freeze-dried powder (18.37%) and lastly by spray-powder (22.16%). From Table 2, vacuum oven drying is the preferred drying method due to its low relative humidity in the chamber which restricted moisture absorption (Xiao & Cai, 2009Xiao, H., & Cai, Y. (2009). Factors affecting relative humidity during wood vacuum drying. Journal of Forestry Research, 20(2), 165-167. http://dx.doi.org/10.1007/s11676-009-0029-8

http://dx.doi.org/10.1007/s11676-009-002...

). Spray-dried powder, on the other hand, had the highest degree of caking due to its high hygroscopicity and small particle size (Goula & Adamopoulos, 2010Goula, A. M., & Adamopoulos, K. G. (2010). A new technique for spray drying orange juice concentrate. Innovative Food Science & Emerging Technologies, 11(2), 342-351. http://dx.doi.org/10.1016/j.ifset.2009.12.001

http://dx.doi.org/10.1016/j.ifset.2009.1...

).

Based on the GEA Niro Research Laboratory (2005)GEA Niro Research Laboratory. (2005). Degree of caking. Retrieved in 2020, April 17, from https://www.gea.com/en/binaries/A%2015%20a%20-%20Degree%20of%20Caking_tcm11-30923.pdf

https://www.gea.com/en/binaries/A%2015%2...

, the caking degree of powder from 10.1% to 20% is categorized as slightly caking powder, whereas values between 20.1% and 50% are caking powder. Hence, all the Kuini powders produced are slightly caking powders except for spray-dried powder (22.16%), which is caking powder. The high degree of caking for spray-dried Kuini powder (22.16%) showed conformity with the findings of Costa et al. (2014)Costa, J. D. P. D., Rocha, É. M. D. F. F., & Costa, J. M. C. D. (2014). Study of the physicochemical characteristics of soursop powder obtained by spray-drying. Food Science and Technology, 34(4), 663-666. http://dx.doi.org/10.1590/1678-457X.6380

http://dx.doi.org/10.1590/1678-457X.6380...

(24.77%). Agustini (2018)Agustini, S. (2018). The characterization of mango (Mangifera indica L) powder of various drying temperature. Journal of Physics: Conference Series, 1095(1), 12035. http://dx.doi.org/10.1088/1742-6596/1095/1/012035

http://dx.doi.org/10.1088/1742-6596/1095...

reported the convection oven-dried mango powder had the degree of caking of 9.62%, which is similar to the findings of present study (12.57%).

The convection oven-dried powder had the lowest angle of repose (10.74°), followed by vacuum oven-dried powder (18.31°), freeze-dried powder (19.60°) and spray-dried powder (25.07°). The Kuini powders had excellent flowability, as evidenced by the angle of repose below 30° (Geldart et al., 1990Geldart, D., Mallet, M. F., & Rolfe, N. (1990). Assessing the flowability of powders using angle of repose. Powder Handling and Processing, 2, 323-346. Retrieved in 2020, April 17, from https://ci.nii.ac.jp/naid/80005621510/en/

https://ci.nii.ac.jp/naid/80005621510/en...

). Reduced flowing properties observed in spray-dried powder was due to its small particle size which resulted in cohesiveness (Jinapong et al., 2008Jinapong, N., Suphantharika, M., & Jamnong, P. (2008). Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. Journal of Food Engineering, 84(2), 194-205. http://dx.doi.org/10.1016/j.jfoodeng.2007.04.032

http://dx.doi.org/10.1016/j.jfoodeng.200...

). Nep & Conway (2011)Nep, E. I., & Conway, B. R. (2011). Physicochemical characterization of grewia polysaccharide gum: Effect of drying method. Carbohydrate Polymers, 84(1), 446-453. http://dx.doi.org/10.1016/j.carbpol.2010.12.005

http://dx.doi.org/10.1016/j.carbpol.2010...

investigated that the freeze-dried powder had higher angle of repose than convection oven-dried powder and such trend was confirmed in this study. Previous studies showed that fruit powders had flowability ranged from 23.14° to 38.06° (Agustini, 2018Agustini, S. (2018). The characterization of mango (Mangifera indica L) powder of various drying temperature. Journal of Physics: Conference Series, 1095(1), 12035. http://dx.doi.org/10.1088/1742-6596/1095/1/012035

http://dx.doi.org/10.1088/1742-6596/1095...

; Dirim & Çaliskan, 2012Dirim, S. N., & Çaliskan, G. (2012). Determination of the effect of freeze drying process on the production of pumpkin (Cucurbita moschata) puree powder and the powder properties. Journal of Food, 37(4), 203-210. Retrieved in 2020, April 17, from https://dergipark.org.tr/en/pub/gida/issue/6933/92554

https://dergipark.org.tr/en/pub/gida/iss...

; Santhalakshmy et al., 2015Santhalakshmy, S., Don Bosco, S. J., Francis, S., & Sabeena, M. (2015). Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technology, 274, 37-43. http://dx.doi.org/10.1016/j.powtec.2015.01.016

http://dx.doi.org/10.1016/j.powtec.2015....

). The Kuini powders in present study had better flowability due to the use of 50% (w/w) maltodextrin, which is higher than other studies. Addition of maltodextrin reduces the cohesiveness of powders and leads to the formation of free flowing powder (Caliskan & Dirim, 2016Caliskan, G., & Dirim, S. N. (2016). The effect of different drying processes and the amounts of maltodextrin addition on the powder properties of sumac extract powders. Powder Technology, 65, 308-314. http://dx.doi.org/10.1016/j.powtec.2015.10.019

http://dx.doi.org/10.1016/j.powtec.2015....

).

3.4 Wettability and water solubility index

Wettability of convection oven-dried powder was the lowest (12.04 s), followed by vacuum oven-dried powder (59.00 s), freeze-dried powder (118.30 s) and spray-dried powder (275.00 s). The low temperature in convection oven drying and vacuum oven drying led to high moisture content thus improving the wetting properties (Phisut, 2012Phisut, N. (2012). Spray drying technique of fruit juice powder: Some factors influencing the properties of product. International Food Research Journal, 19(4), 1297-1306. Retrieved in 2020, April 17, from http://agris.upm.edu.my:8080/dspace/handle/0/11737

http://agris.upm.edu.my:8080/dspace/hand...

). Whereas the small particle size of spray-dried powder had less space between them, thus, inhibiting water penetration (Santhalakshmy et al., 2015Santhalakshmy, S., Don Bosco, S. J., Francis, S., & Sabeena, M. (2015). Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technology, 274, 37-43. http://dx.doi.org/10.1016/j.powtec.2015.01.016

http://dx.doi.org/10.1016/j.powtec.2015....

). Powder that is able to get wet completely within 30 s has very good wettability, 31 s to 60 s is good, 61 s to 120 s is moderate, 121 s to 180 s is weak whereas above 180 s is poor (Berenschot et al., 2013Berenschot, E. P. A., Bogaert, P., Hopmans, N. E., Smith, P., & Wallecan, J. P. R. (2013). U.S. Patent Application 13/697,065.). Hence, the wettability of convection oven-dried powder was very good, vacuum oven-dried powder was good, freeze-dried powder had moderate wettability and spray-dried powder had poor wettability.

The WSI measures the ability of powder to dissolve in water (Schuck et al., 2012Schuck, P., Dolivet, A., & Jeantet, R. (2012). Analytical methods for food and dairy powders. West Sussex: Wiley. http://dx.doi.org/10.1002/9781118307397

http://dx.doi.org/10.1002/9781118307397...

). As presented in Table 2, convection oven-dried and vacuum oven-dried powder had high WSI, with the value of 74.33% and 66.00%, respectively. On the other hand, spray-dried and freeze-dried powder had lower WSI, which were 45.67% and 45.90%, respectively. Convection oven-dried and vacuum oven-dried powder involve low drying temperature which is able to preserve the surface pores and hydrophilic proteins (Phisut, 2012Phisut, N. (2012). Spray drying technique of fruit juice powder: Some factors influencing the properties of product. International Food Research Journal, 19(4), 1297-1306. Retrieved in 2020, April 17, from http://agris.upm.edu.my:8080/dspace/handle/0/11737

http://agris.upm.edu.my:8080/dspace/hand...

). Furthermore, the solubility of freeze-dried Kuini powder was low despite the absence of heat treatment. One possible reason is associated to the cell structure of mango puree that was disrupted during freeze-drying (Puntigo, 2006Puntigo, N. (2006). The development of a drum dryer using the infrared technique in okara powder (Master’s thesis). Asian Institute of Technology, Thailand.).

The high temperature in spray-drying caused damages to the surface pores and hydrophilic proteins. Upon destruction, water molecules were unable to penetrate into the powder and caused reduced solubility (Dao, 2015Dao, V. (2015). Optimization of drum drying process parameters for pumpkin powder production and its substitution in rice noodles. Journal of Science, 3(3), 149-160. Retrieved in 2020, April 17, from http://dspace.agu.edu.vn/bitstream/AGU_Library/2766/1/Vu%20Thi%20Thanh%20Dao.pdf

http://dspace.agu.edu.vn/bitstream/AGU_L...

). The WSI of convection oven-dried Kuini powder determined in current study (74.33%) is lower compared to the findings Agustini (2018)Agustini, S. (2018). The characterization of mango (Mangifera indica L) powder of various drying temperature. Journal of Physics: Conference Series, 1095(1), 12035. http://dx.doi.org/10.1088/1742-6596/1095/1/012035

http://dx.doi.org/10.1088/1742-6596/1095...

(98.90%). Low solubility index can arise when fewer solids dissolve into the supernatant. Santhalakshmy et al. (2015)Santhalakshmy, S., Don Bosco, S. J., Francis, S., & Sabeena, M. (2015). Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technology, 274, 37-43. http://dx.doi.org/10.1016/j.powtec.2015.01.016

http://dx.doi.org/10.1016/j.powtec.2015....

reported that spray-dried plum powder had the WSI of 51.09%, which is close to the value obtained in this study (45.67%).

3.5 Colour of powders, reconstituted powders and total colour change

Colour is an important sensory attribute in food products as it gives the perception of the taste of food and indicates the safety for consumption. Hence, colour analysis is necessary to be carried out. Table 3 shows the Hunter colour measurements of Kuini powders.

Hunter colour measurements of Kuini powders obtained from spray-drying, freeze-drying, vacuum oven drying and convection oven drying method.

L* represents the lightness and darkness of the powder, in which white colour is indicated by 100 and black colour is 0. It was found that the spray-dried powder (89.87) had highest L* value and lightest in colour. While the L* value of freeze-dried, vacuum oven-dried and convection oven-dried powder did not show significant difference, with the range of 81.82 to 82.86. In comparison to the fresh juice (64.93), it was observed that the L* value of Kuini powders increased. The colour of Kuini powders was lighter than the fresh juice due to the addition of 50% (w/w) maltodextrin which was white in colour (Vardin & Yasar, 2011Vardin, H., & Yasar, M. (2011). Optimisation of pomegranate (Punica Granatum L.) juice spray-drying as affected by temperature and maltodextrin content. International Journal of Food Science & Technology, 47(1), 167-176. http://dx.doi.org/10.1111/j.1365-2621.2011.02823.x

http://dx.doi.org/10.1111/j.1365-2621.20...

).

The high L* value of spray-dried powder was attributed by the high drying temperature involved which resulted in the pigment degradation thus yielding light coloured powder (Sousa et al., 2008Sousa, A. S. D., Borges, S. V., Magalhães, N. F., Ricardo, H. V., & Azevedo, A. D. (2008). Spray dried tomato powder: reconstitution properties and colour. Brazilian Archives of Biology and Technology, 51(4), 807-817. http://dx.doi.org/10.1590/S1516-89132008000400019

http://dx.doi.org/10.1590/S1516-89132008...

). Whereas the low drying temperature in freeze-drying was able to preserve the colour pigments and produce slight darker powder than spray-drying. On the other hand, vacuum oven-dried and convection oven-dried powder were darker in colour due to the occurrence of Maillard reaction and caramelization (Abonyi et al., 2002Abonyi, B. I., Feng, H., Tang, J., Edwards, C. G., Chew, B. P., Mattinson, D. S., & Fellman, J. K. (2002). Quality retention in strawberry and carrot purees dried with Refractance WindowTM system. Journal of Food Science, 67(3), 1051-1056. http://dx.doi.org/10.1111/j.1365-2621.2002.tb09452.x

http://dx.doi.org/10.1111/j.1365-2621.20...

).

The a* value indicates the degree of redness (0 to 60) or greenness (0 to -60) of powder. As shown in Table 3, freeze-dried and convection oven-dried powder had higher a* value, with the value of 5.49 and 4.45, respectively. Additionally, vacuum oven-dried and spray-dried powders had lower a* value, which were 2.34 and 1.97, respectively. It was observed that the a* value of powders reduced after drying process and least reduction was obtained by freeze-drying due to the low drying temperature and vacuum environment (Aydin & Gocmen, 2015Aydin, E., & Gocmen, D. (2015). The influences of drying method and metabisulfite pre-treatment on the color, functional properties and phenolic acids content and bioaccessibility of pumpkin flour. Food Science and Technology, 60(1), 385-392. http://dx.doi.org/10.1016/j.lwt.2014.08.025

http://dx.doi.org/10.1016/j.lwt.2014.08....

). In spray-drying, the a* value was the lowest due to the high inlet temperature that led to severe degradation of red pigments.

The b* value represents the degree of yellowness (0 to 60) or blueness (0 to -60) of powder. According to Table 3, freeze-drying resulted in the highest b* value of 57.31. While the b* value of spray-dried, convection oven-dried and vacuum oven-dried powder did not show significant difference, with the range of 29.20 to 30.25. Kuini pulp is yellow colour, therefore, the colour difference caused by different drying methods is best represented by the b* value. Similar trend was obtained by Aydin & Gocmen (2015)Aydin, E., & Gocmen, D. (2015). The influences of drying method and metabisulfite pre-treatment on the color, functional properties and phenolic acids content and bioaccessibility of pumpkin flour. Food Science and Technology, 60(1), 385-392. http://dx.doi.org/10.1016/j.lwt.2014.08.025

http://dx.doi.org/10.1016/j.lwt.2014.08....

, in which freeze-drying showed higher capability in retention of yellowness than convection oven drying due to the low drying temperature. Table 4 shows the Hunter colour measurements of reconstituted Kuini powders and the total colour change.

Hunter colour measurements of reconstituted spray-dried, freeze-dried, vacuum oven-dried and convection oven Kuini powders.

In terms of L* value of the reconstituted Kuini powder, it was found that the spray-dried powder was highest (77.75), followed by freeze-dried powder (57.62), vacuum oven-dried powder (44.01) and lastly by convection oven-dried powder (42.82). Reconstituted freeze-dried powder had highest positive a* value (1.99) and inclined towards red. Whereas convection oven-dried powder (-2.73), spray-dried powder (-4.27) and vacuum oven-dried powder (4.39) had negative a* value, which indicate that the reconstituted powders were inclined towards green. Furthermore, highest b* value was observed in freeze-dried powder (57.25), followed by vacuum oven-dried powder (30.37), convection oven-dried powder (19.76) and lastly by spray-dried powder (13.98). Similar results were obtained by Kha et al. (2010)Kha, T. C., Nguyen, M. H., & Roach, P. D. (2010). Effects of spray drying conditions on the physicochemical and antioxidant properties of the gac (Momordica cochinchinensis) fruit aril powder. Journal of Food Engineering, 98(3), 385-392. http://dx.doi.org/10.1016/j.jfoodeng.2010.01.016

http://dx.doi.org/10.1016/j.jfoodeng.201...

and Jittanit et al. (2010)Jittanit, W., Att, S. N., & Techanuntachaikul, O. (2010). Study of spray drying of pineapple juice using maltodextrin as an adjunct. Warasan Khana Witthayasat Maha Witthayalai Chiang Mai, 37(3), 498-506. Retrieved in 2020, April 17, from https://pdfs.semanticscholar.org/f855/15fa942828e4ea27b91ec1b1c11ff2cf0530.pdf

https://pdfs.semanticscholar.org/f855/15...

whereby the a* and b* value decreased after the drying process.

Table 4 shows that freeze-drying resulted in the least colour change (19.05), followed by vacuum oven-dried powder (46.27), convection oven-dried powder (56.51) and lastly by spray-dried powder (59.81). The low drying temperature and vacuum environment in freeze-drying limited the destruction of pigments (Caparino et al., 2012Caparino, O., Tang, J., Nindo, C., Sablani, S., Powers, J., & Fellman, J. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. Journal of Food Engineering, 111(1), 135-148. http://dx.doi.org/10.1016/j.jfoodeng.2012.01.010

http://dx.doi.org/10.1016/j.jfoodeng.201...

). Furthermore, high drying temperature in spray-drying caused severe beta carotene and colour loss (Quek et al., 2007Quek, S. Y., Chok, N. K., & Swedlund, P. (2007). The physicochemical properties of spray-dried watermelon powders. Chemical Engineering and Processing: Process Intensification, 46(5), 386-392. http://dx.doi.org/10.1016/j.cep.2006.06.020

http://dx.doi.org/10.1016/j.cep.2006.06....

). Similar trend was obtained by Hawlader et al. (2006)Hawlader, M. N. A., Perera, C. O., Tian, M., & Yeo, K. L. (2006). Drying of guava and papaya: Impact of different drying methods. Drying Technology, 24(1), 77-87. http://dx.doi.org/10.1080/07373930500538725

http://dx.doi.org/10.1080/07373930500538...

and Argyropoulos et al. (2011)Argyropoulos, D., Heindl, A., & Müller, J. (2011). Assessment of convection, hot-air combined with microwave-vacuum and freeze-drying methods for mushrooms with regard to product quality. International Journal of Food Science & Technology, 46(2), 333-342. http://dx.doi.org/10.1111/j.1365-2621.2010.02500.x

http://dx.doi.org/10.1111/j.1365-2621.20...

, in which freeze-drying led to minimal colour change compared to vacuum oven drying and convection oven drying. Table 5 shows the effect of drying methods on the antioxidant content.

Effect of drying methods on the total phenolic content (TPC) and total carotenoid (TC) content of Kuini powders.

3.6 Total phenolic content

The phenolic retention of freeze-drying, vacuum oven drying, spray-drying and convection oven drying were 71.77%, 58.09%, 33.28% and 19.36% in decreasing order. The high retention of phenolic content by freeze-drying was due to the absence of heat and the formation of ice crystals. Ice crystals ruptured the cell structure and facilitates the extraction of phenolic compounds (Shih et al., 2009Shih, M. C., Kuo, C. C., & Chiang, W. (2009). Effects of drying and extrusion on colour, chemical composition, antioxidant activities and mitogenic response of spleen lymphocytes of sweet potatoes. Food Chemistry, 117(1), 114-121. http://dx.doi.org/10.1016/j.foodchem.2009.03.084

http://dx.doi.org/10.1016/j.foodchem.200...

). The vacuum condition in vacuum oven drying limited oxidation whereas the high temperature in spray-drying led to severe phenolic degradation. Convection oven-dried Kuini powder had the lowest phenolic content (6.68 mg/100 g) due to the long drying duration and the oxidative enzymes were not inactivated completely (Devic et al., 2010Devic, E., Guyot, S., Daudin, J. D., & Bonazzi, C. (2010). Kinetics of polyphenol losses during soaking and drying of cider apples. Food and Bioprocess Technology, 3(6), 867-877. http://dx.doi.org/10.1007/s11947-010-0361-1

http://dx.doi.org/10.1007/s11947-010-036...

; Mrad et al., 2012Mrad, N. D., Boudhrioua, N., Kechaou, N., Courtois, F., & Bonazzi, C. (2012). Influence of air drying temperature on kinetics, physicochemical properties, total phenolic content and ascorbic acid of pears. Food and Bioproducts Processing, 90(3), 433-441. http://dx.doi.org/10.1016/j.fbp.2011.11.009

http://dx.doi.org/10.1016/j.fbp.2011.11....

).

Similar trend was obtained by Sogi et al. (2015)Sogi, D. S., Siddiq, M., & Dolan, K. D. (2015). Total phenolics, carotenoids and antioxidant properties of Tommy Atkin mango cubes as affected by drying techniques. Food Science and Technology, 62(1), 564-568. http://dx.doi.org/10.1016/j.lwt.2014.04.015

http://dx.doi.org/10.1016/j.lwt.2014.04....

, in which freeze-drying led to the highest retention of phenolic content, followed by vacuum oven drying and convection oven drying. The TPC for freeze-dried Kuini powder determined in present study (24.76 mg/100 g) is in agreement with the values reported by the previous studies, which ranged from 8 mg/100 g to 2664.97 mg/100 g (Ikram et al., 2009Ikram, E. H. K., Eng, K. H., Jalil, A. M. M., Ismail, A., Idris, S., Azlan, A., Nazri, H. S. M., Diton, N. A. M., & Mokhtar, R. A. M. (2009). Antioxidant capacity and total phenolic content of Malaysian underutilized fruits. Journal of Food Composition and Analysis, 22(5), 388-393. http://dx.doi.org/10.1016/j.jfca.2009.04.001

http://dx.doi.org/10.1016/j.jfca.2009.04...

; Mirfat et al., 2015Mirfat, A., Razali, M., Salma, I., & Kalsum, H. (2015). Antioxidant and nutritional values of selected under-utilised Mangifera species in Malaysia. Indian Journal of Plant Genetic Resources, 28(1), 72. http://dx.doi.org/10.5958/0976-1926.2015.00010.8

http://dx.doi.org/10.5958/0976-1926.2015...

). Research studies revealed that the phenolic retention of freeze-dried products ranged from 82.63% to 97.00% whereas phenolic retention of vacuum oven-dried fruits ranged from 44.91% to 73.49% (Gümüşay et al., 2015Gümüşay, Ö. A., Borazan, A. A., Ercal, N., & Demirkol, O. (2015). Drying effects on the antioxidant properties of tomatoes and ginger. Food Chemistry, 173, 156-162. PMid:25466007. http://dx.doi.org/10.1016/j.foodchem.2014.09.162

http://dx.doi.org/10.1016/j.foodchem.201...

; Wojdyło et al., 2009Wojdyło, A., Figiel, A., & Oszmiański, J. (2009). Effect of drying methods with the application of vacuum microwaves on the bioactive compounds, color, and antioxidant activity of strawberry fruits. Journal of Agricultural and Food Chemistry, 57(4), 1337-1343. PMid:19170638. http://dx.doi.org/10.1021/jf802507j

http://dx.doi.org/10.1021/jf802507j...

; Sultana et al., 2012Sultana, B., Anwar, F., Ashraf, M., & Saari, N. (2012). Effect of drying techniques on the total phenolic contents and antioxidant activity of selected fruits. Journal of Medicinal Plants Research, 6(1), 161-167. http://dx.doi.org/10.5897/JMPR11.916

https://doi.org/10.5897/JMPR11.916...

).

3.7 Total carotenoid content

In comparison to the Kuini powders, fresh juice had higher carotenoid content (1.86 mg/100 g) as beta carotene is susceptible to heat destruction (Quek et al., 2007Quek, S. Y., Chok, N. K., & Swedlund, P. (2007). The physicochemical properties of spray-dried watermelon powders. Chemical Engineering and Processing: Process Intensification, 46(5), 386-392. http://dx.doi.org/10.1016/j.cep.2006.06.020

http://dx.doi.org/10.1016/j.cep.2006.06....

). Freeze-dried Kuini powder had the highest carotenoid retention (86.56%), followed by vacuum oven-dried (56.99%), spray-dried (29.57%) and convection oven-dried powder (12.37%). The high carotenoid content of freeze-drying was contributed by the absence of heat and the vacuum environment. In vacuum oven drying, oxidation degradation was limited. The spray-dried powder had higher carotenoid content than convection oven-dried powder due to the short drying time.

Similar trend was obtained by Lin et al. (1998)Lin, T. M., Durance, T. D., & Scaman, C. H. (1998). Characterization of vacuum microwave, air and freeze dried carrot slices. Food Research International, 31(2), 111-117. http://dx.doi.org/10.1016/S0963-9969(98)00070-2

http://dx.doi.org/10.1016/S0963-9969(98)...

, in which air-drying resulted in a greater carotenoid loss than vacuum oven drying and freeze-drying. The carotenoid content of freeze-dried Kuini powder (1.61 mg/100 g) was found lower than the value found by Khoo et al. (2008)Khoo, H. E., Ismail, A., Mohd-Esa, N., & Idris, S. (2008). Carotenoid content of underutilized tropical fruits. Plant Foods for Human Nutrition, 63(4), 170-175. PMid:18810641. http://dx.doi.org/10.1007/s11130-008-0090-z

http://dx.doi.org/10.1007/s11130-008-009...

(3.95 mg/100 g). The carotenoid retention in freeze-drying (86.56%) showed conformity to previous studies which reported values ranged from 74.03% to 96.00% (Dirim & Çaliskan, 2012Dirim, S. N., & Çaliskan, G. (2012). Determination of the effect of freeze drying process on the production of pumpkin (Cucurbita moschata) puree powder and the powder properties. Journal of Food, 37(4), 203-210. Retrieved in 2020, April 17, from https://dergipark.org.tr/en/pub/gida/issue/6933/92554

https://dergipark.org.tr/en/pub/gida/iss...

; Abonyi et al., 2002Abonyi, B. I., Feng, H., Tang, J., Edwards, C. G., Chew, B. P., Mattinson, D. S., & Fellman, J. K. (2002). Quality retention in strawberry and carrot purees dried with Refractance WindowTM system. Journal of Food Science, 67(3), 1051-1056. http://dx.doi.org/10.1111/j.1365-2621.2002.tb09452.x

http://dx.doi.org/10.1111/j.1365-2621.20...

; Link et al., 2017Link, J. V., Tribuzi, G., & Laurindo, J. B. (2017). Improving quality of dried fruits: A comparison between conductive multi-flash and traditional drying methods. LWT, 84, 717-725. http://dx.doi.org/10.1016/j.lwt.2017.06.045

http://dx.doi.org/10.1016/j.lwt.2017.06....

). Similar carotenoid retention in vacuum oven drying was obtained in the studies of gac peel, mango and cherry, which were 49.67%, 50.10% and 50.28%, respectively (Chuyen et al., 2017Chuyen, H. V., Roach, P. D., Golding, J. B., Parks, S. E., & Nguyen, M. H. (2017). Effects of four different drying methods on the carotenoid composition and antioxidant capacity of dried gac peel. Journal of the Science of Food and Agriculture, 97(5), 1656-1662. PMid:27435184. http://dx.doi.org/10.1002/jsfa.7918

http://dx.doi.org/10.1002/jsfa.7918...

; Link et al., 2017Link, J. V., Tribuzi, G., & Laurindo, J. B. (2017). Improving quality of dried fruits: A comparison between conductive multi-flash and traditional drying methods. LWT, 84, 717-725. http://dx.doi.org/10.1016/j.lwt.2017.06.045

http://dx.doi.org/10.1016/j.lwt.2017.06....

; Nóbrega et al., 2014Nóbrega, E. M., Oliveira, E. L., Genovese, M. I., & Correia, R. T. P. (2014). The impact of hot air drying on the physical-chemical characteristics, bioactive compounds and antioxidant activity of acerola (Malphigia emarginata) residue. Journal of Food Processing and Preservation, 39(2), 131-141. http://dx.doi.org/10.1111/jfpp.12213

http://dx.doi.org/10.1111/jfpp.12213...

). It was reported that retention of carotenoids was 31.28% and 27.08% after spray-drying (Kha et al., 2010Kha, T. C., Nguyen, M. H., & Roach, P. D. (2010). Effects of spray drying conditions on the physicochemical and antioxidant properties of the gac (Momordica cochinchinensis) fruit aril powder. Journal of Food Engineering, 98(3), 385-392. http://dx.doi.org/10.1016/j.jfoodeng.2010.01.016

http://dx.doi.org/10.1016/j.jfoodeng.201...

; Quek et al., 2007Quek, S. Y., Chok, N. K., & Swedlund, P. (2007). The physicochemical properties of spray-dried watermelon powders. Chemical Engineering and Processing: Process Intensification, 46(5), 386-392. http://dx.doi.org/10.1016/j.cep.2006.06.020

http://dx.doi.org/10.1016/j.cep.2006.06....

).

4 Conclusions

Drying led to the shrinkage and loss in the pigments as well as antioxidant content in the powder. The freeze-dried powder had the highest yellowness, total phenolic content and total carotenoid content. Severe colour change and caking was observed in the spray-dried Kuini powder whereas the least colour change was determined in freeze-dried Kuini powder. This study could conclude that freeze-drying was the best drying method for the production of fruit powders with desirable powder characteristics. However, the cost for freeze-drying is expensive and the drying process is time-consuming. Therefore, vacuum oven drying is an alternative method to produce powders with adequate properties.

-

Cite as: Shuen, G. W., Yi, L. Y., Ying, T. S., Von, G. C. Y., Yusof, Y. A. B., & Phing, P. L. (2021). Effects of drying methods on the physicochemical properties and antioxidant capacity of Kuini powder. Brazilian Journal of Food Technology, 24, e2020086. https://doi.org/10.1590/1981-6723.08620

-

Funding: None.

References

- Abonyi, B. I., Feng, H., Tang, J., Edwards, C. G., Chew, B. P., Mattinson, D. S., & Fellman, J. K. (2002). Quality retention in strawberry and carrot purees dried with Refractance WindowTM system. Journal of Food Science, 67(3), 1051-1056. http://dx.doi.org/10.1111/j.1365-2621.2002.tb09452.x

» http://dx.doi.org/10.1111/j.1365-2621.2002.tb09452.x - Agustini, S. (2018). The characterization of mango (Mangifera indica L) powder of various drying temperature. Journal of Physics: Conference Series, 1095(1), 12035. http://dx.doi.org/10.1088/1742-6596/1095/1/012035

» http://dx.doi.org/10.1088/1742-6596/1095/1/012035 - Argyropoulos, D., Heindl, A., & Müller, J. (2011). Assessment of convection, hot-air combined with microwave-vacuum and freeze-drying methods for mushrooms with regard to product quality. International Journal of Food Science & Technology, 46(2), 333-342. http://dx.doi.org/10.1111/j.1365-2621.2010.02500.x

» http://dx.doi.org/10.1111/j.1365-2621.2010.02500.x - Aydin, E., & Gocmen, D. (2015). The influences of drying method and metabisulfite pre-treatment on the color, functional properties and phenolic acids content and bioaccessibility of pumpkin flour. Food Science and Technology, 60(1), 385-392. http://dx.doi.org/10.1016/j.lwt.2014.08.025

» http://dx.doi.org/10.1016/j.lwt.2014.08.025 - Berenschot, E. P. A., Bogaert, P., Hopmans, N. E., Smith, P., & Wallecan, J. P. R. (2013). U.S. Patent Application 13/697,065.

- Brennan, J. G., & Grandison, A. S. (2006). Food processing handbook (pp. 105-110). Germany: Wiley.

- Brooke, P., & Lau, C. (2013). Nutritional value and economic potential of underutilised Mangifera species in Bungai Area, Sarawak, Malaysia. Acta Horticulturae, 979(8), 107-115. http://dx.doi.org/10.17660/ActaHortic.2013.979.8

» http://dx.doi.org/10.17660/ActaHortic.2013.979.8 - Cai, Y. Z., & Corke, H. (2000). Production and properties of spray‐dried Amaranthus betacyanin pigments. Journal of Food Science, 65(7), 1248-1252. http://dx.doi.org/10.1111/j.1365-2621.2000.tb10273.x

» http://dx.doi.org/10.1111/j.1365-2621.2000.tb10273.x - Caliskan, G., & Dirim, S. N. (2016). The effect of different drying processes and the amounts of maltodextrin addition on the powder properties of sumac extract powders. Powder Technology, 65, 308-314. http://dx.doi.org/10.1016/j.powtec.2015.10.019

» http://dx.doi.org/10.1016/j.powtec.2015.10.019 - Caparino, O., Tang, J., Nindo, C., Sablani, S., Powers, J., & Fellman, J. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. Journal of Food Engineering, 111(1), 135-148. http://dx.doi.org/10.1016/j.jfoodeng.2012.01.010

» http://dx.doi.org/10.1016/j.jfoodeng.2012.01.010 - Carlos, L. A., Resende, J. V., & Vidal, J. C. (2005). Hygroscopicity reduction of post-lyophilized by inducing crystallization in model solutions constituents of fruit sugars. Brazilian Journal of Food Technology, 8(2), 163-173. http://dx.doi.org/10.1590/1807-1929/agriambi.v20n3p269-274

» https://doi.org/10.1590/1807-1929/agriambi.v20n3p269-274 - Ceballos, A. M., Giraldo, G. I., & Orrego, C. E. (2012). Effect of freezing rate on quality parameters of freeze dried soursop fruit pulp. Journal of Food Engineering, 111(2), 360-365. http://dx.doi.org/10.1016/j.jfoodeng.2012.02.010

» http://dx.doi.org/10.1016/j.jfoodeng.2012.02.010 - Chang, L. S., Tan, Y. L., & Pui, L. P. (2020a). Production of spray-dried enzyme-liquefied papaya (Carica papaya L.) powder. Brazilian Journal of Food Technology, 23, e2019181. http://dx.doi.org/10.1590/1981-6723.18119

» http://dx.doi.org/10.1590/1981-6723.18119 - Chang, L. S., Yong, S. M. E., & Pui, L. P. (2020b). Production of Spray-dried “Terung Asam” (Solanum lasiocarpum Dunal) Powder. Walailak Journal of Science and Technology In press.

- Chew, S., & Tan, C. (2019). PUI; CHONG, P.; GUNASEKARAN, B.; NYAM, K. Encapsulation technologies: A tool for functional foods development. International Journal of Innovative Technology and Exploring Engineering, 8(5S), 154-160.

- Chuyen, H. V., Roach, P. D., Golding, J. B., Parks, S. E., & Nguyen, M. H. (2017). Effects of four different drying methods on the carotenoid composition and antioxidant capacity of dried gac peel. Journal of the Science of Food and Agriculture, 97(5), 1656-1662. PMid:27435184. http://dx.doi.org/10.1002/jsfa.7918

» http://dx.doi.org/10.1002/jsfa.7918 - Costa, J. D. P. D., Rocha, É. M. D. F. F., & Costa, J. M. C. D. (2014). Study of the physicochemical characteristics of soursop powder obtained by spray-drying. Food Science and Technology, 34(4), 663-666. http://dx.doi.org/10.1590/1678-457X.6380

» http://dx.doi.org/10.1590/1678-457X.6380 - Dailami, M. T. (2009). Production of dragon fruit powder using spray drying method (Doctoral dissertation). Universiti Malaysia Pahang, Malaysia.

- Dao, V. (2015). Optimization of drum drying process parameters for pumpkin powder production and its substitution in rice noodles. Journal of Science, 3(3), 149-160. Retrieved in 2020, April 17, from http://dspace.agu.edu.vn/bitstream/AGU_Library/2766/1/Vu%20Thi%20Thanh%20Dao.pdf

» http://dspace.agu.edu.vn/bitstream/AGU_Library/2766/1/Vu%20Thi%20Thanh%20Dao.pdf - Devic, E., Guyot, S., Daudin, J. D., & Bonazzi, C. (2010). Kinetics of polyphenol losses during soaking and drying of cider apples. Food and Bioprocess Technology, 3(6), 867-877. http://dx.doi.org/10.1007/s11947-010-0361-1

» http://dx.doi.org/10.1007/s11947-010-0361-1 - Dirim, S. N., & Çaliskan, G. (2012). Determination of the effect of freeze drying process on the production of pumpkin (Cucurbita moschata) puree powder and the powder properties. Journal of Food, 37(4), 203-210. Retrieved in 2020, April 17, from https://dergipark.org.tr/en/pub/gida/issue/6933/92554

» https://dergipark.org.tr/en/pub/gida/issue/6933/92554 - GEA Niro Research Laboratory. (2005). Degree of caking. Retrieved in 2020, April 17, from https://www.gea.com/en/binaries/A%2015%20a%20-%20Degree%20of%20Caking_tcm11-30923.pdf

» https://www.gea.com/en/binaries/A%2015%20a%20-%20Degree%20of%20Caking_tcm11-30923.pdf - Geldart, D., Mallet, M. F., & Rolfe, N. (1990). Assessing the flowability of powders using angle of repose. Powder Handling and Processing, 2, 323-346. Retrieved in 2020, April 17, from https://ci.nii.ac.jp/naid/80005621510/en/

» https://ci.nii.ac.jp/naid/80005621510/en/ - Gobbetti, M., Cagno, R. D., & De Angelis, M. (2010). Functional microorganisms for functional food quality. Critical Reviews in Food Science and Nutrition, 50(8), 716-727. PMid:20830633. http://dx.doi.org/10.1080/10408398.2010.499770

» http://dx.doi.org/10.1080/10408398.2010.499770 - Gopinathan, M., Yusof, Y. A., & Pui, L. P. (2020). Effects of different drying methods on the physicochemical and antioxidant content of ‘cempedak’ (Artocarpus integer L.) powder. Journal of Food Processing and Preservation, 44(12), (in press) http://dx.doi.org/10.1111/jfpp.14966

» http://dx.doi.org/10.1111/jfpp.14966 - Goula, A. M., & Adamopoulos, K. G. (2010). A new technique for spray drying orange juice concentrate. Innovative Food Science & Emerging Technologies, 11(2), 342-351. http://dx.doi.org/10.1016/j.ifset.2009.12.001

» http://dx.doi.org/10.1016/j.ifset.2009.12.001 - Gümüşay, Ö. A., Borazan, A. A., Ercal, N., & Demirkol, O. (2015). Drying effects on the antioxidant properties of tomatoes and ginger. Food Chemistry, 173, 156-162. PMid:25466007. http://dx.doi.org/10.1016/j.foodchem.2014.09.162

» http://dx.doi.org/10.1016/j.foodchem.2014.09.162 - Guo, Z., Chen, X., Liu, H., Guo, Q., Guo, X., & Lu, H. (2014). Theoretical and experimental investigation on angle of repose of biomass-coal blends. Fuel, 116, 131-139. http://dx.doi.org/10.1016/j.fuel.2013.07.098

» http://dx.doi.org/10.1016/j.fuel.2013.07.098 - Hawlader, M. N. A., Perera, C. O., Tian, M., & Yeo, K. L. (2006). Drying of guava and papaya: Impact of different drying methods. Drying Technology, 24(1), 77-87. http://dx.doi.org/10.1080/07373930500538725

» http://dx.doi.org/10.1080/07373930500538725 - Hui, Y. H. (Ed.). (2008). Food drying science and technology: Microbiology, chemistry, applications. Lancaster: DEStech Publications.

- Ikram, E. H. K., Eng, K. H., Jalil, A. M. M., Ismail, A., Idris, S., Azlan, A., Nazri, H. S. M., Diton, N. A. M., & Mokhtar, R. A. M. (2009). Antioxidant capacity and total phenolic content of Malaysian underutilized fruits. Journal of Food Composition and Analysis, 22(5), 388-393. http://dx.doi.org/10.1016/j.jfca.2009.04.001

» http://dx.doi.org/10.1016/j.jfca.2009.04.001 - Jaya, S., & Das, H. (2003). A vacuum drying model for mango pulp. Drying Technology: An International Journal, 21(7), 1215-1234. http://dx.doi.org/10.1081/DRT-120023177

» http://dx.doi.org/10.1081/DRT-120023177 - Jaya, S., & Das, H. (2009). Glass transition and sticky point temperatures and stability/mobility diagram of fruit powders. Food and Bioprocess Technology, 2(1), 89-95. http://dx.doi.org/10.1007/s11947-007-0047-5

» http://dx.doi.org/10.1007/s11947-007-0047-5 - Jinapong, N., Suphantharika, M., & Jamnong, P. (2008). Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. Journal of Food Engineering, 84(2), 194-205. http://dx.doi.org/10.1016/j.jfoodeng.2007.04.032

» http://dx.doi.org/10.1016/j.jfoodeng.2007.04.032 - Jittanit, W., Att, S. N., & Techanuntachaikul, O. (2010). Study of spray drying of pineapple juice using maltodextrin as an adjunct. Warasan Khana Witthayasat Maha Witthayalai Chiang Mai, 37(3), 498-506. Retrieved in 2020, April 17, from https://pdfs.semanticscholar.org/f855/15fa942828e4ea27b91ec1b1c11ff2cf0530.pdf

» https://pdfs.semanticscholar.org/f855/15fa942828e4ea27b91ec1b1c11ff2cf0530.pdf - Kha, T. C., Nguyen, M. H., & Roach, P. D. (2010). Effects of spray drying conditions on the physicochemical and antioxidant properties of the gac (Momordica cochinchinensis) fruit aril powder. Journal of Food Engineering, 98(3), 385-392. http://dx.doi.org/10.1016/j.jfoodeng.2010.01.016

» http://dx.doi.org/10.1016/j.jfoodeng.2010.01.016 - Khoo, H. E., Ismail, A., Mohd-Esa, N., & Idris, S. (2008). Carotenoid content of underutilized tropical fruits. Plant Foods for Human Nutrition, 63(4), 170-175. PMid:18810641. http://dx.doi.org/10.1007/s11130-008-0090-z

» http://dx.doi.org/10.1007/s11130-008-0090-z - Lim, Y. Y., Lim, T. T., & Tee, J. J. (2007). Antioxidant properties of several tropical fruits: A comparative study. Food Chemistry, 103(3), 1003-1008. http://dx.doi.org/10.1016/j.foodchem.2006.08.038

» http://dx.doi.org/10.1016/j.foodchem.2006.08.038 - Lim, T. K. (Ed.). (2012). Edible medicinal and non-medicinal plants. Dordrecht: Springer.

- Lin, T. M., Durance, T. D., & Scaman, C. H. (1998). Characterization of vacuum microwave, air and freeze dried carrot slices. Food Research International, 31(2), 111-117. http://dx.doi.org/10.1016/S0963-9969(98)00070-2

» http://dx.doi.org/10.1016/S0963-9969(98)00070-2 - Link, J. V., Tribuzi, G., & Laurindo, J. B. (2017). Improving quality of dried fruits: A comparison between conductive multi-flash and traditional drying methods. LWT, 84, 717-725. http://dx.doi.org/10.1016/j.lwt.2017.06.045

» http://dx.doi.org/10.1016/j.lwt.2017.06.045 - Loo, Y. Y., & Pui, L. P. (2020). Storage stability of kuini (Mangifera odorata) powder in aluminum laminated polyethylene and polyethylene terephthalate. The Malaysian Journal of Analytical Sciences, 24(5), 657-669. Retrieved in 2020, April 17, from https://mjas.analis.com.my/mjas/v24_n5/pdf/Loo_24_5_4.pdf

» https://mjas.analis.com.my/mjas/v24_n5/pdf/Loo_24_5_4.pdf - Mirfat, A., Razali, M., Salma, I., & Kalsum, H. (2015). Antioxidant and nutritional values of selected under-utilised Mangifera species in Malaysia. Indian Journal of Plant Genetic Resources, 28(1), 72. http://dx.doi.org/10.5958/0976-1926.2015.00010.8

» http://dx.doi.org/10.5958/0976-1926.2015.00010.8 - Moreira, G. E. G., Costa, M. G. M., Souza, A. C. R., Brito, E. S., Meideros, M. F. D., & Azeredo, H. M. C. (2009). Physical properties of spray dried acerola pomace extract as affected by temperature and drying aids. Food Science and Technology, 42(2), 642-645. http://dx.doi.org/10.1016/j.lwt.2008.07.008

» http://dx.doi.org/10.1016/j.lwt.2008.07.008 - Mrad, N. D., Boudhrioua, N., Kechaou, N., Courtois, F., & Bonazzi, C. (2012). Influence of air drying temperature on kinetics, physicochemical properties, total phenolic content and ascorbic acid of pears. Food and Bioproducts Processing, 90(3), 433-441. http://dx.doi.org/10.1016/j.fbp.2011.11.009

» http://dx.doi.org/10.1016/j.fbp.2011.11.009 - Nep, E. I., & Conway, B. R. (2011). Physicochemical characterization of grewia polysaccharide gum: Effect of drying method. Carbohydrate Polymers, 84(1), 446-453. http://dx.doi.org/10.1016/j.carbpol.2010.12.005

» http://dx.doi.org/10.1016/j.carbpol.2010.12.005 - Nóbrega, E. M., Oliveira, E. L., Genovese, M. I., & Correia, R. T. P. (2014). The impact of hot air drying on the physical-chemical characteristics, bioactive compounds and antioxidant activity of acerola (Malphigia emarginata) residue. Journal of Food Processing and Preservation, 39(2), 131-141. http://dx.doi.org/10.1111/jfpp.12213

» http://dx.doi.org/10.1111/jfpp.12213 - Phisut, N. (2012). Spray drying technique of fruit juice powder: Some factors influencing the properties of product. International Food Research Journal, 19(4), 1297-1306. Retrieved in 2020, April 17, from http://agris.upm.edu.my:8080/dspace/handle/0/11737

» http://agris.upm.edu.my:8080/dspace/handle/0/11737 - Pua, C. K., Hamid, N. S. A., Tan, C. P., Mirhosseini, H., Rahman, R. B. A., & Rusul, G. (2010). Optimization of drum drying processing parameters for production of jackfruit (Artocarpus heterophyllus) powder using response surface methodology. Food Science and Technology, 43(2), 343-349. http://dx.doi.org/10.1016/j.lwt.2009.08.011

» http://dx.doi.org/10.1016/j.lwt.2009.08.011 - Pui, L. P., Karim, R., Yusof, Y. A., Wong, C. W., & Ghazali, H. M. (2020a). Optimization of spray-drying parameters for the production of ‘Cempedak’ (Artocarpus integer) fruit powder. Journal of Food Measurement and Characterization, 14(6), 3238-3249. http://dx.doi.org/10.1007/s11694-020-00565-3

» http://dx.doi.org/10.1007/s11694-020-00565-3 - Pui, L. P., Karim, R., Yusof, Y. A., Wong, C. W., & Ghazali, H. M. (2020b). Anti-caking agent effects on the properties of spray-dried ‘cempedak’ fruit powder. Journal of Tropical Agricultural Science In press.

- Puntigo, N. (2006). The development of a drum dryer using the infrared technique in okara powder (Master’s thesis). Asian Institute of Technology, Thailand.

- Quek, S. Y., Chok, N. K., & Swedlund, P. (2007). The physicochemical properties of spray-dried watermelon powders. Chemical Engineering and Processing: Process Intensification, 46(5), 386-392. http://dx.doi.org/10.1016/j.cep.2006.06.020

» http://dx.doi.org/10.1016/j.cep.2006.06.020 - Ribeiro, L., Costa, J., & Afonso, M. (2016). Hygroscopic behavior of lyophilized acerola pulp powder. Brazilian Journal of Agricultural and Environmental Engineering, 20(3), 269-274. http://dx.doi.org/10.1590/1807-1929/agriambi.v20n3p269-274

» http://dx.doi.org/10.1590/1807-1929/agriambi.v20n3p269-274 - Santhalakshmy, S., Don Bosco, S. J., Francis, S., & Sabeena, M. (2015). Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technology, 274, 37-43. http://dx.doi.org/10.1016/j.powtec.2015.01.016

» http://dx.doi.org/10.1016/j.powtec.2015.01.016 - Sarabandi, K., Peighambardoust, S. H., & Shirmohammadi, M. (2014). Physical properties of spray dried grape syrup as affected by drying temperature and drying aids. International Journal of Agriculture and Crop Sciences, 7(12), 928-934. Retrieved in 2020, April 17, from https://pdfs.semanticscholar.org/7912/3ad58df9435ce5ae8bd14728ab5fd281b2f4.pdf

» https://pdfs.semanticscholar.org/7912/3ad58df9435ce5ae8bd14728ab5fd281b2f4.pdf - Schuck, P., Dolivet, A., & Jeantet, R. (2012). Analytical methods for food and dairy powders West Sussex: Wiley. http://dx.doi.org/10.1002/9781118307397

» http://dx.doi.org/10.1002/9781118307397 - Scrob, S., Muste, S., Haș, I., Mureșan, C., Socaci, S., & Fărcaș, A. (2014). Total content of carotenoids in corn landraces and their potential health applications. Bulletin UASVM Food Science and Technology, 71(2), 96-100. http://dx.doi.org/10.15835/buasvmcn-fst:10396