ABSTRACT

The objective of this study was to investigate the effects of slaughter body weight (SW) on the performance, carcass characteristics, and meat quality of Jersey bulls in feedlots from weaning to slaughter. Eighteen Jersey bulls (125.7±15.9 kg; 5±0.6 months old) were used in the study. The treatments corresponded to three slaughter-weights: L360 – light weight, SW of 360 kg, M390 – medium weight, SW of 390 kg, and H420 – heavy weight, SW of 420 kg (n = 6/treatment); the animals were slaughtered at 368, 392, and 422 kg, respectively. The average daily gain was not influenced by SW. The M390 and H420 groups remained in feedlot, on average, 6 and 51 d longer, respectively, to reach a similar SW in relation to the L360 group. The increase in SW did not influence dry matter intake. However, the L360 group exhibited greater dry matter intake relative to body weight compared with the other two groups (29 vs. 26 g/kg). The increase in SW resulted in heavier and longer carcasses, with higher hot carcass yields. However, animals with greater SW had lower fat thickness. In addition, the increase in SW led to greater pistol cut, bone, and muscle weight for the carcasses. Although the meat color of Jersey bulls was darker in the H420 group, the meat was considered softer and more palatable by the consumer panel compared with the meat from the L360 group. The L360 group exhibited less fluid loss during thawing and cooking. Shear force measured by Warner Blatzer Shear was lower for H420. Animals slaughtered in the L390 group had an intermediate carcass weight, similar carcass yield, better cover fat and meat quality (color and shear) than animals slaughtered in the H420. Combining these factors with a shorter feedlot time compared with that of heavier animals, the SW of feedlot Jersey bulls is recommended at 390 kg.

Keywords:

carcass quality; dairy male; meat; performance; super young

1. Introduction

In countries with developed dairy farming, dairy male calves are used for meat production and represent a significant portion of the meat consumed by the population. According to Berry et al. (2018)Berry, D. P.; Judge, M. J.; Evans, R. D.; Buckley, F. and Cromie, A. R. 2018. Carcass characteristics of cattle differing in Jersey proportion. Journal of Dairy Science 101:11052-11060. https://doi.org/10.3168/jds.2018-14992

https://doi.org/10.3168/jds.2018-14992...

, the contribution of beef output to the revenue of dairy enterprises is well recognized. Van der Werf et al. (1998)Van der Werf, J. H. J.; Van der Waaij, L. H.; Groen, A. F. and De Jong, G. 1998. An index for beef and veal characteristics in dairy cattle based on carcass traits. Livestock Production Science 54:11-20. https://doi.org/10.1016/S0301-6226(97)00167-X

https://doi.org/10.1016/S0301-6226(97)00...

suggested that surplus calves and culled cow sales constituted 10 to 20% of the gross income from a dairy herd. However, in poorer countries, this type of animal has no market value because its production is expensive and there is little market demand.

Alternative use of these animals is the traditional fattening and slaughtering of older, heavier individuals. However, several studies have shown that compared with beef breeds, dairy breeds or their crossbreeds are associated with lower yield carcasses, carcass fat (including subcutaneous fat), and conformation, fewer edible portions as well as problems with yellow fat and minor tenderness ( Coleman et al., 2016Coleman, L. W.; Hickson, R. E.; Schreurs, N. M.; Martin, N. P.; Kenyon, P. R.; Lopez-Villalobos, N. and Morris, S. T. 2016. Carcass characteristics and meat quality of Hereford sired steers born to beef-cross-dairy and Angus breeding cows. Meat Science 121:403-408. https://doi.org/10.1016/j.meatsci.2016.07.011

https://doi.org/10.1016/j.meatsci.2016.0...

). McNamee et al. (2015)McNamee, A.; Keane, M. G.; Kenny, D. A.; Moloney, A. P.; Buckley, F. and O’ Riordan, E. G. 2015. Beef production from Holstein-Friesian, Norwegian Red × Holstein-Friesian and Jersey × Holstein-Friesian male cattle reared as bulls or steers. Livestock Science 173:95-105. https://doi.org/10.1016/j.livsci.2014.12.009

https://doi.org/10.1016/j.livsci.2014.12...

stated that animals crossed with the Jersey breed exhibited the worst carcass traits and performance compared with those of other dairy breeds. These authors claimed that Jersey cows had particularly unacceptable commercial traits in terms of carcass shape or muscle size. However, Berry et al. (2018)Berry, D. P.; Judge, M. J.; Evans, R. D.; Buckley, F. and Cromie, A. R. 2018. Carcass characteristics of cattle differing in Jersey proportion. Journal of Dairy Science 101:11052-11060. https://doi.org/10.3168/jds.2018-14992

https://doi.org/10.3168/jds.2018-14992...

demonstrated that, although inferior carcass characteristics were associated with an increase in the proportion of Jersey in the breed, animals with a Jersey bloodline had superior meat quality and nutritive value compared with that of many other breeds. Albertí et al. (2008)Albertí, P.; Panea, B.; Sañudo, C.; Olleta, J. L.; Ripoll, G.; Ertbjerg, P.; Christensen, M.; Gigli, S.; Failla, S.; Concetti, S.; Hocquette, J. F.; Jailler, R.; Rudel, S.; Renand, G.; Nute, G. R.; Richardson, R. I. and Williams, J. L. 2008. Live weight, body size and carcass characteristics of young bulls of fifteen European breeds. Livestock Science 114:19-30. https://doi.org/10.1016/j.livsci.2007.04.010

https://doi.org/10.1016/j.livsci.2007.04...

showed that Jersey cattle demonstrated the potential to produce a highly marbled product, and according to Arnett et al. (2012)Arnett, E. J.; Fluharty, F. L.; Loerch, S. C.; Zerby, H. N.; Zinn, R. A. and Kuber, P. S. 2012. Effects of forage level in feedlot finishing diets on carcass characteristics and palatability of Jersey beef. Journal of Animal Science 90:960-972. https://doi.org/10.2527/jas.2011-4027

https://doi.org/10.2527/jas.2011-4027...

, this may create an opportunity for a niche market. Under a grain-based feeding system, Pitchford et al. (2002)Pitchford, W. S.; Deland, M. P. B.; Siebert, B. D.; Malau-Aduli, A. E. O. and Bottema, C. D. K. 2002. Genetic variation in fatness and fatty acid composition of crossbred cattle. Journal of Animal Science 80:2825-2832. https://doi.org/10.2527/2002.80112825x

https://doi.org/10.2527/2002.80112825x...

observed that Jersey carcasses had similar levels of intramuscular fat as the highly prized Wagyu and Angus breeds. Killinger et al. (2004)Killinger, K. M.; Calkins, C. R.; Umberger, W. J.; Feuz, D. M. and Eskridge, K. M. 2004. Consumer sensory acceptance and value for beef steaks of similar tenderness, but differing in marbling level. Journal of Animal Science 82:3294-3301. https://doi.org/10.2527/2004.82113294x

https://doi.org/10.2527/2004.82113294x...

observed that consumers were willing to pay a premium for beef with moderate (USDA Choice+) or modest (USDA Choice) marbling than for beef with slight (USDA Select−/+) marbling.

McNamee et al. (2015)McNamee, A.; Keane, M. G.; Kenny, D. A.; Moloney, A. P.; Buckley, F. and O’ Riordan, E. G. 2015. Beef production from Holstein-Friesian, Norwegian Red × Holstein-Friesian and Jersey × Holstein-Friesian male cattle reared as bulls or steers. Livestock Science 173:95-105. https://doi.org/10.1016/j.livsci.2014.12.009

https://doi.org/10.1016/j.livsci.2014.12...

suggested that the Jersey breed should be preferably produced as bulls rather than steers. These authors concluded that for Jersey bulls, the heaviest carcasses were the most acceptable commercially because of their better conformation and higher fat class than that of lighter animals. However, Pacheco et al. (2014)Pacheco, P. S.; Pascoal, L. L.; Restle, J.; Vaz, F. N.; Arboitte, M. Z.; Vaz, R. Z.; Santos, J. P. A. and Oliveira, T. M. L. 2014. Risk assessment of finishing beef cattle in feedlot: Slaughter weights and correlation amongst input variables. Revista Brasileira de Zootecnia 43:92-99. https://doi.org/10.1590/S1516-35982014000200007

https://doi.org/10.1590/S1516-3598201400...

found that an increase in slaughter body weight (SW) resulted in a high possibility of economically unsuccessful feedlot activity.

We hypothesized that rising the SW will improves the qualitative characteristics of both the carcass and meat without impairing the performance of Jersey bulls. This research was conducted to investigate the effects of three SW of Jersey bulls kept in feedlot from weaning to slaughter.

2. Material and Methods

The experiment was conducted in Pato Branco, Paraná, Brazil (26° 07′36.0″ S, 52° 39′03.0″ W) from May 2017 to September 2018. The study was conducted according to the rules of the institutional Animal Use Ethics Committee (CEUA), under case no. 2017-004.

Eighteen Jersey bulls with an average live weight of 125.7±15.9 kg and 5±0.6 months old were used in the study. The experimental groups were divided into three slaughter-weight classes: L360 – light weight, SW of 360 kg, M390 – medium weight, SW of 390 kg, and H420 – heavy weight, SW of 420 kg, with six animals per group. Bulls were kept in feedlot facilities consisting of individual 3×3 m stalls equipped with individual troughs measuring 1.15 linear m per animal and held automatically refilled drinkers. At the onset of the experiment, the animals were weighed post-fasting, dewormed, and acclimated to diets and facilities for 15 d before the start of the trial. Diets were formulated in accordance with NRC (2000NRC - National Research Council. 2000. Nutrient requirements of beef cattle. 7th ed. National Academies Press, Washington, D.C. ). The diet was calculated for an expected average daily gain (ADG) of 1300 g/day and a dry matter intake (DMI) of 26 g/kg live weight (LW). The feed consisted of 850 g/kg concentrate plus 150 g/kg oat hay, which was the only roughage source. The concentrate was composed of ground corn (680 g/kg of total dry matter (DM)) and soybean meal (170 g/kg of total DM) and was supplied with the roughage twice daily, in the morning and afternoon (09:00 and 17:00 h, respectively). The diet consisted of 178 g/kg DM of crude protein (CP), 226 g/kg DM of neutral detergent fiber (NDF), 294 g/kg DM of acid detergent fiber (ADF), 838 g/kg DM of total digestible nutrients (TDN), and 866 g/kg DM of in vitro dry matter digestibility.

The leftovers were removed and weighed daily before the first feeding of the day to adjust the quantity to be supplied. The diet amount was calculated to be approximately 10% leftovers. In each pen, mineral salt mixed with Rumensin® (15 g/kg) ad libitum was made available for the bulls.

The animals were weighed at the beginning and end of the experimental period as well as every 30 days to monitor their weight development. When group weights were approached, the intervals for weighing were shortened. The weighing was performed 14 h after liquid and solid fasting. Representative samples were collected from the components of the diet (concentrate and roughage) as well as from feed leftovers at the beginning of the acclimation period and weekly during the experimental period. The samples were pre-dried in a forced-air oven at 55 °C for 72 h. The content of the partial DM was determined, and the samples were milled in a “Willey” type mill with a 1-mm mesh sieve. Nutritional composition analyses were performed in the laboratory. Total DM content was determined by oven drying at 105 °C for 8 h (method 967.03; AOAC 1998AOAC - Association of Official Analytical Chemistry. 1998. Official methods of analysis of the Association of Official Analytical Chemistry. 16th ed. AOAC International, Arlington, VA. ), and ash content was measured by burning in a muffle furnace at 600 °C for 4 h. The organic matter (OM) content was calculated as 100 – ash content (method 942.05; AOAC, 1998AOAC - Association of Official Analytical Chemistry. 1998. Official methods of analysis of the Association of Official Analytical Chemistry. 16th ed. AOAC International, Arlington, VA. ). Estimations of the TDN from the OM digestibility were calculated based on the equation described by Kunkle and Bates (1998)Kunkle, W. E. and Bates, D. B. 1998. Evaluating feed purchasing options: energy, protein, and mineral supplements. p.59-70. In: Proceedings of the Florida Beef Cattle Short Course. Gainesville.:

in which TDN = total digestible nutrients (%), OM = organic matter (%), and IVOMD = in vitro organic matter digestibility (%).

The NDF and ADF contents were determined according to the methods of Van Soest et al. (1991)Van Soest, P. J.; Robertson, J. B. and Lewis, B. A. 1991. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. Journal of Dairy Science 74:3583-3597. https://doi.org/10.3168/jds.S0022-0302(91)78551-2

https://doi.org/10.3168/jds.S0022-0302(9...

. Sixteen-micron polyester bags were autoclaved at 110 °C for 40 min ( Komarek et al., 1993Komarek, R. J.; Gardner, R. M.; Buchanan, C. M. and Gedon, S. 1993. Biodegradation of radiolabeled cellulose acetate and cellulose propionate. Journal of Applied Polymer Science 50:1739-1746. https://doi.org/10.1002/app.1993.070501009

https://doi.org/10.1002/app.1993.0705010...

; Senger et al., 2008Senger, C. C. D.; Kozloski, G. V.; Bonnecarrère Sanchez, L. M.; Mesquita, F. R.; Alves, T. P. and Castagnino, D. S. 2008. Evaluation of autoclave procedures for fibre analysis in forage and concentrate feedstuffs. Animal Feed Science and Technology 146:169-174. https://doi.org/10.1016/j.anifeedsci.2007.12.008

https://doi.org/10.1016/j.anifeedsci.200...

). Crude protein was determined indirectly from the total nitrogen (N) value × 6.25, with N estimated using the Kjeldahl method (method 984.13; AOAC, 2006AOAC - Association of Official Analytical Chemistry. 2006. Official methods of analysis of the Association of Official Analytical Chemistry. 17th ed. AOAC International, Arlington, VA. ).

The in vitro dry matter digestibility (IVDMD) was estimated using a technique adapted from Tilley and Terry (1963)Tilley, J. M. A. and Terry, R. A. 1963. A two‐stage technique for the in vitro digestion of forage crops. Grass and Forage Science 18:104-111. https://doi.org/10.1111/j.1365-2494.1963.tb00335.x

https://doi.org/10.1111/j.1365-2494.1963...

, using the in vitro incubator TE-150 Tecnal®. Approximately 0.5 g of previously dried and ground samples were weighed, put into 16 µ-porosity polyester bags, and submerged for 48 h in a buffer ( Goering and Van Soest 1970Goering, K. H. and Van Soest, P. J. 1970. Forage fiber analysis: apparatus, reagents, procedures, and some applications. Department of Agriculture, Washington, D.C. ; Komarek et al., 1993Komarek, R. J.; Gardner, R. M.; Buchanan, C. M. and Gedon, S. 1993. Biodegradation of radiolabeled cellulose acetate and cellulose propionate. Journal of Applied Polymer Science 50:1739-1746. https://doi.org/10.1002/app.1993.070501009

https://doi.org/10.1002/app.1993.0705010...

) with 20% ruminal inoculum collected from two fistulated Jersey steers (CEUA, case no. 2014-008). Then, the samples were treated in a neutral detergent solution for 40 min at 105 °C in an autoclave ( Goering and Van Soest, 1970Goering, K. H. and Van Soest, P. J. 1970. Forage fiber analysis: apparatus, reagents, procedures, and some applications. Department of Agriculture, Washington, D.C. ; Senger et al., 2008Senger, C. C. D.; Kozloski, G. V.; Bonnecarrère Sanchez, L. M.; Mesquita, F. R.; Alves, T. P. and Castagnino, D. S. 2008. Evaluation of autoclave procedures for fibre analysis in forage and concentrate feedstuffs. Animal Feed Science and Technology 146:169-174. https://doi.org/10.1016/j.anifeedsci.2007.12.008

https://doi.org/10.1016/j.anifeedsci.200...

).

Slaughter body weight was measured using a digital scale immediately before the bulls were taken to a commercial slaughterhouse after a fasting period of 12 h. After slaughter, the carcasses were identified to determine the hot carcass weight (HCW), which was measured at the end of the slaughter line immediately after bleeding, evisceration, and removal of hides, head, and feet. Cold carcass weight (CCW) was obtained after the carcass was chilled for 24 h in a cold room at 0±1 °C. Hot and cold carcass yield (HCY, CCY) were calculated by multiplying the HCW or CCW by 100 and dividing by SW. A section was taken from between the 11th and 12th ribs of the right half of the cold carcass, designated as the HH section, in accordance with methodology proposed by Hankins and Howe (1946)Hankins, O. G. and Howe, P. E. 1946. Estimation of the composition of beef carcasses and cuts. Technical Bulletin – USDA, 926. United Sates Department of Agriculture, Washington, D.C. and adapted by Muller (1987)Muller, L. 1987. Normas para avaliação de carcaças e concurso de carcaça de novilhos. 2.ed. Imprensa Universitária, Santa Maria. . From that section, the muscle, fat, and bone tissues were physically separated for determination of the total quantity and percentage of these tissues relative to the cold carcass.

After 24 h of chilling, at 0±1 °C, measurements were taken from the right half of the carcasses. Carcass length (as determined with a measuring tape from the cranial border in the mid-portion of the first rib to the cranial border of the pubic bone) and the weight of the primal cuts of the pistol, forequarter, and short ribs were recorded. Their percentage was expressed relative to the cold carcass weight. The pistol cut corresponded to the back region of the carcass, which was separated from the forequarter between the 5th and 6th ribs at approximately 22 cm from the spine. The forequarter cut included the neck, shoulder, forelegs, and five ribs. The short ribs were comprised of six ribs that were separated at approximately 22 cm from the spine and abdominal muscles.

Carcass conformation was determined for the right half of the carcass after 24 h of chilling in a cold room using a subjective assessment following the methodology described by Muller (1987)Muller, L. 1987. Normas para avaliação de carcaças e concurso de carcaça de novilhos. 2.ed. Imprensa Universitária, Santa Maria. . In this method, muscle expression of the carcass was estimated using an 18-point scale with emphasis on the pistol cut, in which the cuts of the highest commercial value are located. Marbling was evaluated on a transverse section of the longissimus dorsi muscle at the 12th rib of the left half of the carcass. This variable was assessed subjectively according to the number and size of granules of intramuscular fat, for which scores of 1 to 18 were assigned (1 to 3 = traces; 4 to 6 = slight; 7 to 9 = little; 10 to 12 = medium; 13 to 15 = moderate; 16 to 18 = abundant), as described by Muller (1987)Muller, L. 1987. Normas para avaliação de carcaças e concurso de carcaça de novilhos. 2.ed. Imprensa Universitária, Santa Maria. . Back fat thickness was measured at three points along the longissimus dorsi muscle from the left half of the carcass with calipers. Values were expressed in millimeters and consisted of the arithmetic mean of three measurements. The loin-eye area was also measured on the longissimus dorsi muscle from the left half of the carcass, by making a transverse section between the 12th and 13th ribs and outlining it on tracing paper. The area was then determined in square centimeters using the image and AUTOCAD® software. Meat color and texture were determined subjectively after 24 h of carcass chilling for a transverse section of the longissimus dorsi made at the 12th rib on the left half of the carcass after exposing the muscle to constant oxygenation and luminosity for 30 min. The color was classified on a scale of 1 to 5 (1 = extremely dark meat; 5 = extremely light meat). The texture was assessed based on the granulation of muscle fiber bundles on the exposed surface of the sectioned muscle, with scores ranging from 1 (extremely thick) to 5 (extremely fine) Muller (1987)Muller, L. 1987. Normas para avaliação de carcaças e concurso de carcaça de novilhos. 2.ed. Imprensa Universitária, Santa Maria. .

Subsequently, from each sample still frozen, 2.5-cm slices (slices A, B, and C) were extracted perpendicular to the muscle length. One of the slices (slice A) was weighed frozen and thawed to determine the break during the meat defrosting process and after cooking to an internal temperature of 70 °C to determine the break in the meat cooking process. Using this slice, after cooking and cooling, three circular 1 cm² samples perpendicular to the muscle fibers were removed, and for every two readings, the Warner Bratzler Shear was used to determine the shear force of the muscle. Using the other slices (slices B and C), the sensory evaluation of the meat (tenderness, palatability, and juiciness) was performed with a panel of 10 trained tasters who assigned values from 1 (extremely hard, unpalatable, and without juiciness) to 9 (extremely tender, palatable, and juicy meat) to the meat following the methodology described by Muller (1987)Muller, L. 1987. Normas para avaliação de carcaças e concurso de carcaça de novilhos. 2.ed. Imprensa Universitária, Santa Maria. .

The experimental design was completely randomized with three SW and six repetitions. Data were subjected to a test for normality. Variance analysis was performed following the GLM procedure of SAS (Statistical Analysis System, version 9.1). In case of a significant effect of the treatment factor, the means were compared using the Tukey test. Initial weight was used as a covariate to adjust the mathematical model. In the case of a significant effect (α<0.05), the covariate was used to adjust the means of the other variables.

The data were analyzed using the following mathematical model:

in which Yij is the dependent variable, μ is the average of all observations, αi is the effect of the i-th SW, is the effect of covariate x initial weight on experimental units of the i-th treatment, and εij = residual random error.

Performance variables were also evaluated throughout the feedlot period as the animals increased in weight using a regression analysis, wherein the initial weight was used as a covariate and the live weight was used as a fixed effect. For this analysis, we used the average performance data (live weight, ADG, and DM intake, absolute and relative to live weight and feed conversion) every 60 days, except after 240 d of feedlot. After 240 d, the final feedlot time was used, which was different for each animal, according to performance.

3. Results

The slaughtered animals had weights close to those pre-stipulated at the beginning of the experiment (368.3, 392.0, and 421.8 kg). The ADG was not influenced (P = 0.5106) by SW ( Table 1 ). Thus, the feedlot period was a factor in the SW. The animals in the M390 and H420 groups remained, on average, 6 and 51 d more (P = 0.0278), respectively, to reach the SW compared with animals in the L360 group. The increase in SW did not influence (P = 0.4440) the average DMI. However, the L360 group presented a greater (P = 0.0415) DMI relative to body weight compared with that of the other groups (29 vs. 26 g/kg). The lack of difference in ADG and DMI reflected the similarity (P = 0.3785) of feed conversion for all SW.

Averages for performance characteristics of Jersey bulls finished in feedlot with different slaughter weights

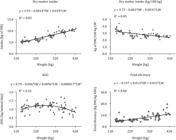

Evaluating the DMI (absolute and relative), ADG, and feed conversion over the feedlot period ( Figure 1 ), it was observed that as the weight of the animals increased, these characteristics varied. As expected, absolute DMI increased with increasing weight of animals and consequent increases in ingestive capacity. However, intake relative to 100 kg of live weight decreased with animal weight. The ADG, on the other hand, increased to 282 kg of live weight and decreased from this weight ( Figure 1 ). The increase in DMI and decrease in ADG during most feedlots provided an increase in feed conversion for animals over time.

Absolute and relative dry matter intake, average daily weight gain (ADG), and feed conversion of Jersey bulls according to their weight evolution.

The increase in SW resulted in heavier (P<0.0001) and longer (P = 0.0099) carcasses and higher (P = 0.0260) HCY ( Table 2 ). However, the animals with greater SW had lower fat thickness (P = 0.0317). In addition, the increase in SW led to greater pistol cut (P = 0.0219), bone (P = 0.0164), and muscle (P = 0.0011) weight ( Table 3 ).

Averages for performance characteristics of Jersey bulls finished in feedlot with different slaughter weights

Cut yield and tissue composition of carcass of Jersey bulls finished in feedlot with different slaughter weights

The meat color of Jersey bulls was darker (P = 0.0262) at the highest SW (H420), but their meat was considered softer (P = 0.0348) and more palatable (P = 0.0452) by the consumer panel compared with the meat of the M390 group ( Table 4 ). Although it presented less fluid loss during thawing (P = 0.0012) and cooking (P = 0.0027), meat from animals slaughtered in the H420 group was not considered more succulent than M390. The shear force measured by Warner Blatzer Shear was lower (P = 0.0042) for the H420 animals.

Objective and subjective analyses of organoleptic characteristics of meat of Jersey bulls finished in feedlot with different slaughter weights

4. Discussion

Despite presenting good weight gains (1160 g/day on average), being a breed not specialized for meat production, the animals were retained in feedlot for a long period. This is because of the low weight (125.7 kg) at the beginning of the finishing phase. Arnett et al. (2012)Arnett, E. J.; Fluharty, F. L.; Loerch, S. C.; Zerby, H. N.; Zinn, R. A. and Kuber, P. S. 2012. Effects of forage level in feedlot finishing diets on carcass characteristics and palatability of Jersey beef. Journal of Animal Science 90:960-972. https://doi.org/10.2527/jas.2011-4027

https://doi.org/10.2527/jas.2011-4027...

explained that Jersey cattle are slower-growing than other breeds, Jersey cattle require a much longer time on feed to produce carcasses with acceptable carcass weights. One way to minimize this problem is to start the feedlot period with older and heavier animals. However, this practice could lead to decreased carcass yield because these animals will have been fed on pasture and thus may have greater development of the gastrointestinal tract because of the additional fibrous diet ( Prado et al., 2015Prado, I. N.; Passetti, R. A. C.; Rivaroli, D. C.; Ornaghi, M. G.; Souza, K. A.; Carvalho, C. B.; Perotto, D. and Moletta, J. L. 2015. Carcass composition and cuts of bulls and steers fed with three concentrate levels in the diets. Asian-Australasian Journal of Animal Sciences 28:1309-1316. https://doi.org/10.5713/ajas.15.0021

https://doi.org/10.5713/ajas.15.0021...

). On the other hand, Arnett et al. (2012)Arnett, E. J.; Fluharty, F. L.; Loerch, S. C.; Zerby, H. N.; Zinn, R. A. and Kuber, P. S. 2012. Effects of forage level in feedlot finishing diets on carcass characteristics and palatability of Jersey beef. Journal of Animal Science 90:960-972. https://doi.org/10.2527/jas.2011-4027

https://doi.org/10.2527/jas.2011-4027...

stated that long feedlot periods may contribute to improvement in the desirable carcass characteristics of Jersey cows, such as increased meat marbling, as noted by Albertí et al. (2008)Albertí, P.; Panea, B.; Sañudo, C.; Olleta, J. L.; Ripoll, G.; Ertbjerg, P.; Christensen, M.; Gigli, S.; Failla, S.; Concetti, S.; Hocquette, J. F.; Jailler, R.; Rudel, S.; Renand, G.; Nute, G. R.; Richardson, R. I. and Williams, J. L. 2008. Live weight, body size and carcass characteristics of young bulls of fifteen European breeds. Livestock Science 114:19-30. https://doi.org/10.1016/j.livsci.2007.04.010

https://doi.org/10.1016/j.livsci.2007.04...

; however, this was not observed in the present study.

Considering the live weight of these animals (259.5 kg during feedlot), the relative daily gain (g/kg of live weight) was greater than that in beef cattle breeds. Considering an animal with initial live weight of 390 kg and 560 kg of slaughter weight (475 kg on average LW), with ADG of 1700 g/day, the relative ADG would be of 3.58 g/kg LW, while the animals of the present study showed 4.47 g/kg of relative gain.

The observed ADG was greater than that observed by Albertí et al. (2008)Albertí, P.; Panea, B.; Sañudo, C.; Olleta, J. L.; Ripoll, G.; Ertbjerg, P.; Christensen, M.; Gigli, S.; Failla, S.; Concetti, S.; Hocquette, J. F.; Jailler, R.; Rudel, S.; Renand, G.; Nute, G. R.; Richardson, R. I. and Williams, J. L. 2008. Live weight, body size and carcass characteristics of young bulls of fifteen European breeds. Livestock Science 114:19-30. https://doi.org/10.1016/j.livsci.2007.04.010

https://doi.org/10.1016/j.livsci.2007.04...

for Jersey cattle, which are one of the slowest-growing (ADG, 1.08 kg/day) breeds compared with 15 European breeds under feedlot conditions. However, although there was no significant difference in the overall average, according to the regression equation, all animals showed a reduction in ADG from a live weight of 292 kg, with a steeper fall between 360 and 420 kg. This decrease in performance may be linked to a decrease in DMI relative to 100 kg of live weight, despite the expected increase in absolute intake with the increase in animal weight. The NRC (2000NRC - National Research Council. 2000. Nutrient requirements of beef cattle. 7th ed. National Academies Press, Washington, D.C. ) reported that reductions in feed intake as live weight increases are associated with leptin activity, which indicates the presence of elevated body fat deposition. The reduction in ADG typical of older animals is primarily caused by the greater energy demands of physiological maintenance and those related to the composition of the weight gained ( Dias et al., 2018Dias, A. M. O.; Menezes, L. F. G.; Paris, W.; Paula, F. L. M.; Schmitz, G. R.; Souza, S. S.; Umezaki, A. M. and Farias Filho, J. A. 2018. Performance and fatty acid profile of Holstein calves slaughtered at different weights. Revista Brasileira de Zootecnia 47:e20170208. https://doi.org/10.1590/rbz4720170208

https://doi.org/10.1590/rbz4720170208...

).

This decrease in the performance of animals in the final phase of the feedlot may explain the decrease in fat thickness of the heaviest animals. This was not expected in feedlot animals. The literature provides positive results for fat thickness in the carcass when it increases the SW of animals ( Costa et al., 2002Costa, E. C.; Restle, J.; Vaz, F. N.; Alves Filho, D. C.; Bernardes, R. A. L. C. and Kuss, F. 2002. Características da carcaça de novilhos Red Angus superprecoces abatidos com diferentes pesos. Revista Brasileira de Zootecnia 31:119-128. https://doi.org/10.1590/S1516-35982002000100014

https://doi.org/10.1590/S1516-3598200200...

; Arboitte et al., 2004Arboitte, M. Z.; Restle, J.; Alves Filho, D. C.; Pascoal, L. L.; Pacheco, P. S. and Soccal, D. C. 2004. Características da carcaça de novilhos 5/8 Nelore-3/8 Charolês abatidos em diferentes estádios de desenvolvimento. Revista Brasileira de Zootecnia 33:969-977. https://doi.org/10.1590/S1516-35982004000400017

https://doi.org/10.1590/S1516-3598200400...

). However, these authors used castrated animals of beef breeds. The fact that the animals in the present study were not castrated may have contributed to this decrease in performance and fat deposition because the heavier animals were approximately 11 to 12 months old during the last 60 days of feedlot, and already exhibited signs of puberty (restlessness and aggression). The decrease in fat thickness with SW in young animals was corroborated by Paris et al. (2015)Paris, W.; Santos, P. V.; Menezes, L. F. G.; Kuss, F.; Silveira, M. F.; Boito, B.; Venturini, T. and Stanqueviski, F. 2015. Quantitative carcass traits of Holstein calves, finished in different systems and slaughter weights. Ciência Rural 45:505-511. https://doi.org/10.1590/0103-8478cr20141178

https://doi.org/10.1590/0103-8478cr20141...

. Fat thickness is important to protect the carcasses from the harmful effects of intense and sudden cooling to which carcasses are subjected in slaughterhouses. The fat thickness is important to protect the carcass during cooling, in which the fibers may be shortened by the cold, making the meat dark and dry. As a result, slaughterhouses require a minimum fat thickness of 3 mm, which was achieved in L360 and M390 groups.

Previous studies indicate darker muscle from bulls compared with steers ( Dunne et al., 2004Dunne, P. G.; Keane, M. G.; O’Mara, F. P.; Monahan, F. J. and Moloney, A. P. 2004. Colour of subcutaneous adipose tissue and M. longissimus dorsi of high index dairy and beef × dairy cattle slaughtered at two liveweights as bulls and steers. Meat Science 68:97-106. https://doi.org/10.1016/j.meatsci.2004.02.010

https://doi.org/10.1016/j.meatsci.2004.0...

), and this has been related to a higher pH in bulls compared with that in steers ( Purchas et al., 2002Purchas, R. W.; Burnham, D. L. and Morris, S. T. 2002. Effects of growth potential and growth path on tenderness of beef longissimus muscle from bulls and steers. Journal of Animal Science 80:3211-3221. https://doi.org/10.2527/2002.80123211x

https://doi.org/10.2527/2002.80123211x...

). The main reason for the differences in pH between the two groups has been attributed to the increased stress ( Field, 1971Field, R. A. 1971. Effect of castration on meat quality and quantity. Journal of Animal Science 32:849-858. https://doi.org/10.2527/jas1971.325849x

https://doi.org/10.2527/jas1971.325849x...

) and sexual activity ( Katz, 2007Katz, L. S. 2007. Sexual behavior of domesticated ruminants. Hormones and Behavior 52:56-63. https://doi.org/10.1016/j.yhbeh.2007.03.012

https://doi.org/10.1016/j.yhbeh.2007.03....

) of bulls. This information explains the darker meat of the heavier animals with the assumption that these animals were in puberty.

Among cattle, low carcass yield is a shortcoming unique to dairy breeds. According to Fernandes et al. (2004)Fernandes, H. J.; Paulino, M. F.; Martins, R. G. R.; Valadares Filho, S. C.; Torres, R. A.; Paiva, L. M. and Silva, A. T. S. 2004. Composição corporal de garrotes inteiros de três grupos genéticos nas fases de recria e terminação. Revista Brasileira de Zootecnia 33:1581-1590. https://doi.org/10.1590/S1516-35982004000600026

https://doi.org/10.1590/S1516-3598200400...

, animals selected for meat production generally have carcass yields 7% higher than those of dairy breeds, because of less fat present in the carcass, viscera, and gastrointestinal tract ( Coleman et al., 2016Coleman, L. W.; Hickson, R. E.; Schreurs, N. M.; Martin, N. P.; Kenyon, P. R.; Lopez-Villalobos, N. and Morris, S. T. 2016. Carcass characteristics and meat quality of Hereford sired steers born to beef-cross-dairy and Angus breeding cows. Meat Science 121:403-408. https://doi.org/10.1016/j.meatsci.2016.07.011

https://doi.org/10.1016/j.meatsci.2016.0...

). Slaughter of very young animals fed high amounts of concentrate could minimize this problem. In the present study, as carcass weight advanced, there was an increase in HCY. However, this difference did not remain after cooling, possibly because of the lower fat thickness presented by these animals and, consequently, less protection against the loss of liquids during cooling.

Increasing SW provided better quality meats, according to the evaluator panel. Sañudo et al. (2004)Sañudo, C.; Macie, E. S.; Olleta, J. L.; Villarroel, M.; Panea, B. and Albertí, P. 2004. The effects of slaughter weight, breed type and ageing time on beef meat quality using two different texture devices. Meat Science 66:925-932. https://doi.org/10.1016/j.meatsci.2003.08.005

https://doi.org/10.1016/j.meatsci.2003.0...

observed that meat from heavier animals was significantly more tender, with slight variations depending on the breed. These authors explained that these unexpected results regarding meat tenderness after heating (greater meat tenderness in older animals) occurred because some connective tissue characteristics were quite similar in both SW (i.e., total and insoluble collagen content). In addition, the longissimus dorsi muscle has a low collagen content, and the increase in toughness with animal age is greater in muscles with a high collagen content ( Sañudo et al., 2004Sañudo, C.; Macie, E. S.; Olleta, J. L.; Villarroel, M.; Panea, B. and Albertí, P. 2004. The effects of slaughter weight, breed type and ageing time on beef meat quality using two different texture devices. Meat Science 66:925-932. https://doi.org/10.1016/j.meatsci.2003.08.005

https://doi.org/10.1016/j.meatsci.2003.0...

).

As with the taster panel, the shear force of the heaviest animals was lower, in agreement with previous results ( Sañudo et al., 2004Sañudo, C.; Macie, E. S.; Olleta, J. L.; Villarroel, M.; Panea, B. and Albertí, P. 2004. The effects of slaughter weight, breed type and ageing time on beef meat quality using two different texture devices. Meat Science 66:925-932. https://doi.org/10.1016/j.meatsci.2003.08.005

https://doi.org/10.1016/j.meatsci.2003.0...

). Bouton et al. (1978)Bouton, P. E.; Ford, A. L.; Harris, P. V.; Shorthose, W. R.; Ratcliff, D. and Morgan, J. H. L. 1978. Influence of animal age on the tenderness of beef: Muscle differences. Meat Science 2:301-311. https://doi.org/10.1016/0309-1740(78)90031-1

https://doi.org/10.1016/0309-1740(78)900...

found that when muscles were restrained from shortening, tenderness increased with animal age. Nonetheless, Sañudo et al. (2004)Sañudo, C.; Macie, E. S.; Olleta, J. L.; Villarroel, M.; Panea, B. and Albertí, P. 2004. The effects of slaughter weight, breed type and ageing time on beef meat quality using two different texture devices. Meat Science 66:925-932. https://doi.org/10.1016/j.meatsci.2003.08.005

https://doi.org/10.1016/j.meatsci.2003.0...

reported that the longissimus dorsi is often exposed during carcass chilling, and the degree of exposure affects shortening.

The similarity in the degree of marbling could be attributed to the small difference in the finishing time between SW. The amount of marbling fat is generally related to the degree of finishing, which in turn is a function of time and the composition of the finisher ration ( Waritthitham et al., 2010Waritthitham, A.; Lambertz, C.; Langholz, H. J.; Wicke, M. and Gauly, M. 2010. Assessment of beef production from Brahman × Thai native and Charolais × Thai native crossbred bulls slaughtered at different weights. II: Meat quality. Meat Science 85:196-200. https://doi.org/10.1016/j.meatsci.2009.12.025

https://doi.org/10.1016/j.meatsci.2009.1...

). Killinger et al. (2004)Killinger, K. M.; Calkins, C. R.; Umberger, W. J.; Feuz, D. M. and Eskridge, K. M. 2004. Consumer sensory acceptance and value for beef steaks of similar tenderness, but differing in marbling level. Journal of Animal Science 82:3294-3301. https://doi.org/10.2527/2004.82113294x

https://doi.org/10.2527/2004.82113294x...

observed that consumers are willing to pay a premium for beef with moderate (USDA Choice+) or modest (USDA Choice) marbling compared with Slight (USDA Select−/+) marbling. Under a grain-based feeding system, Jersey carcasses had similar levels of intramuscular fat as the highly prized Wagyu and Angus ( Arnett et al., 2012Arnett, E. J.; Fluharty, F. L.; Loerch, S. C.; Zerby, H. N.; Zinn, R. A. and Kuber, P. S. 2012. Effects of forage level in feedlot finishing diets on carcass characteristics and palatability of Jersey beef. Journal of Animal Science 90:960-972. https://doi.org/10.2527/jas.2011-4027

https://doi.org/10.2527/jas.2011-4027...

).

With the exception of cold carcass yield, all traits presented adequate values for the exploitation of the Jersey breed as a meat producer. The tenderness of the meat leads to better results than that of several young animal breeds specialized in meat production ( Costa et al., 2002Costa, E. C.; Restle, J.; Vaz, F. N.; Alves Filho, D. C.; Bernardes, R. A. L. C. and Kuss, F. 2002. Características da carcaça de novilhos Red Angus superprecoces abatidos com diferentes pesos. Revista Brasileira de Zootecnia 31:119-128. https://doi.org/10.1590/S1516-35982002000100014

https://doi.org/10.1590/S1516-3598200200...

; Waritthitham et al., 2010Waritthitham, A.; Lambertz, C.; Langholz, H. J.; Wicke, M. and Gauly, M. 2010. Assessment of beef production from Brahman × Thai native and Charolais × Thai native crossbred bulls slaughtered at different weights. II: Meat quality. Meat Science 85:196-200. https://doi.org/10.1016/j.meatsci.2009.12.025

https://doi.org/10.1016/j.meatsci.2009.1...

; Bureš and Barton, 2012Bureš, D. and Bartoň, L. 2012. Growth performance, carcass traits and meat quality of bulls and heifers slaughtered at different ages. Czech Journal of Animal Science 57:34-43. https://doi.org/10.17221/5482-CJAS

https://doi.org/10.17221/5482-CJAS...

) and could be used as a marketing factor for the sale of a differentiated product with added value. The good meat quality is in agreement with a previous study by Berry et al. (2018)Berry, D. P.; Judge, M. J.; Evans, R. D.; Buckley, F. and Cromie, A. R. 2018. Carcass characteristics of cattle differing in Jersey proportion. Journal of Dairy Science 101:11052-11060. https://doi.org/10.3168/jds.2018-14992

https://doi.org/10.3168/jds.2018-14992...

.

In an intensive production system, economic factors must be considered when making decisions. In the present study, the acceptability of the carcasses by the slaughterhouses (carcass weight and cover fat) and the feedlot time (extremely long) were key factors in choosing the best SW. The animals slaughtered with 390 kg of live weight presented these desirable characteristics.

Brazil still has a fragile carcass classification system, which evaluates only age, carcass weight, and fat thickness. Quality characteristics such as tenderness and marbling are only valued by the promotion programs of breed associations. The Brazilian system, like most slaughterhouses, requires carcasses with a minimum of 240 kg for a good classification. In the present study, carcass weight was the only attribute that did not meet the minimum requirements. However, the meat of these animals presented good tenderness and marbling and could be sold as premium meat.

There are still some challenges to be met, such as carcass weight, yield, and time to finish. Although Jersey cattle face challenges in the high demand for beef production, they have the potential to produce high-quality, tender beef products.

5. Conclusions

Animals slaughtered in the 390 kg group had an intermediate carcass weight, similar carcass yield, and better cover fat and meat quality (color and shear) than animals slaughtered in the 420 kg group. Combining these factors with a shorter feedlot time compared with that of heavier animals, the slaughter body weight of feedlot Jersey bulls is recommended at 390 kg.

Acknowledgments

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) - Finance Code 001 and Unidade Mista de Pesquisa e Transferência de Tecnologia (UMIPTT – UTFPR/EMBRAPA).

References

- Albertí, P.; Panea, B.; Sañudo, C.; Olleta, J. L.; Ripoll, G.; Ertbjerg, P.; Christensen, M.; Gigli, S.; Failla, S.; Concetti, S.; Hocquette, J. F.; Jailler, R.; Rudel, S.; Renand, G.; Nute, G. R.; Richardson, R. I. and Williams, J. L. 2008. Live weight, body size and carcass characteristics of young bulls of fifteen European breeds. Livestock Science 114:19-30. https://doi.org/10.1016/j.livsci.2007.04.010

» https://doi.org/10.1016/j.livsci.2007.04.010 - AOAC - Association of Official Analytical Chemistry. 1998. Official methods of analysis of the Association of Official Analytical Chemistry. 16th ed. AOAC International, Arlington, VA.

- AOAC - Association of Official Analytical Chemistry. 2006. Official methods of analysis of the Association of Official Analytical Chemistry. 17th ed. AOAC International, Arlington, VA.

- Arboitte, M. Z.; Restle, J.; Alves Filho, D. C.; Pascoal, L. L.; Pacheco, P. S. and Soccal, D. C. 2004. Características da carcaça de novilhos 5/8 Nelore-3/8 Charolês abatidos em diferentes estádios de desenvolvimento. Revista Brasileira de Zootecnia 33:969-977. https://doi.org/10.1590/S1516-35982004000400017

» https://doi.org/10.1590/S1516-35982004000400017 - Arnett, E. J.; Fluharty, F. L.; Loerch, S. C.; Zerby, H. N.; Zinn, R. A. and Kuber, P. S. 2012. Effects of forage level in feedlot finishing diets on carcass characteristics and palatability of Jersey beef. Journal of Animal Science 90:960-972. https://doi.org/10.2527/jas.2011-4027

» https://doi.org/10.2527/jas.2011-4027 - Berry, D. P.; Judge, M. J.; Evans, R. D.; Buckley, F. and Cromie, A. R. 2018. Carcass characteristics of cattle differing in Jersey proportion. Journal of Dairy Science 101:11052-11060. https://doi.org/10.3168/jds.2018-14992

» https://doi.org/10.3168/jds.2018-14992 - Bouton, P. E.; Ford, A. L.; Harris, P. V.; Shorthose, W. R.; Ratcliff, D. and Morgan, J. H. L. 1978. Influence of animal age on the tenderness of beef: Muscle differences. Meat Science 2:301-311. https://doi.org/10.1016/0309-1740(78)90031-1

» https://doi.org/10.1016/0309-1740(78)90031-1 - Bureš, D. and Bartoň, L. 2012. Growth performance, carcass traits and meat quality of bulls and heifers slaughtered at different ages. Czech Journal of Animal Science 57:34-43. https://doi.org/10.17221/5482-CJAS

» https://doi.org/10.17221/5482-CJAS - Coleman, L. W.; Hickson, R. E.; Schreurs, N. M.; Martin, N. P.; Kenyon, P. R.; Lopez-Villalobos, N. and Morris, S. T. 2016. Carcass characteristics and meat quality of Hereford sired steers born to beef-cross-dairy and Angus breeding cows. Meat Science 121:403-408. https://doi.org/10.1016/j.meatsci.2016.07.011

» https://doi.org/10.1016/j.meatsci.2016.07.011 - Costa, E. C.; Restle, J.; Vaz, F. N.; Alves Filho, D. C.; Bernardes, R. A. L. C. and Kuss, F. 2002. Características da carcaça de novilhos Red Angus superprecoces abatidos com diferentes pesos. Revista Brasileira de Zootecnia 31:119-128. https://doi.org/10.1590/S1516-35982002000100014

» https://doi.org/10.1590/S1516-35982002000100014 - Dias, A. M. O.; Menezes, L. F. G.; Paris, W.; Paula, F. L. M.; Schmitz, G. R.; Souza, S. S.; Umezaki, A. M. and Farias Filho, J. A. 2018. Performance and fatty acid profile of Holstein calves slaughtered at different weights. Revista Brasileira de Zootecnia 47:e20170208. https://doi.org/10.1590/rbz4720170208

» https://doi.org/10.1590/rbz4720170208 - Dunne, P. G.; Keane, M. G.; O’Mara, F. P.; Monahan, F. J. and Moloney, A. P. 2004. Colour of subcutaneous adipose tissue and M. longissimus dorsi of high index dairy and beef × dairy cattle slaughtered at two liveweights as bulls and steers. Meat Science 68:97-106. https://doi.org/10.1016/j.meatsci.2004.02.010

» https://doi.org/10.1016/j.meatsci.2004.02.010 - Fernandes, H. J.; Paulino, M. F.; Martins, R. G. R.; Valadares Filho, S. C.; Torres, R. A.; Paiva, L. M. and Silva, A. T. S. 2004. Composição corporal de garrotes inteiros de três grupos genéticos nas fases de recria e terminação. Revista Brasileira de Zootecnia 33:1581-1590. https://doi.org/10.1590/S1516-35982004000600026

» https://doi.org/10.1590/S1516-35982004000600026 - Field, R. A. 1971. Effect of castration on meat quality and quantity. Journal of Animal Science 32:849-858. https://doi.org/10.2527/jas1971.325849x

» https://doi.org/10.2527/jas1971.325849x - Goering, K. H. and Van Soest, P. J. 1970. Forage fiber analysis: apparatus, reagents, procedures, and some applications. Department of Agriculture, Washington, D.C.

- Hankins, O. G. and Howe, P. E. 1946. Estimation of the composition of beef carcasses and cuts. Technical Bulletin – USDA, 926. United Sates Department of Agriculture, Washington, D.C.

- Katz, L. S. 2007. Sexual behavior of domesticated ruminants. Hormones and Behavior 52:56-63. https://doi.org/10.1016/j.yhbeh.2007.03.012

» https://doi.org/10.1016/j.yhbeh.2007.03.012 - Killinger, K. M.; Calkins, C. R.; Umberger, W. J.; Feuz, D. M. and Eskridge, K. M. 2004. Consumer sensory acceptance and value for beef steaks of similar tenderness, but differing in marbling level. Journal of Animal Science 82:3294-3301. https://doi.org/10.2527/2004.82113294x

» https://doi.org/10.2527/2004.82113294x - Komarek, R. J.; Gardner, R. M.; Buchanan, C. M. and Gedon, S. 1993. Biodegradation of radiolabeled cellulose acetate and cellulose propionate. Journal of Applied Polymer Science 50:1739-1746. https://doi.org/10.1002/app.1993.070501009

» https://doi.org/10.1002/app.1993.070501009 - Kunkle, W. E. and Bates, D. B. 1998. Evaluating feed purchasing options: energy, protein, and mineral supplements. p.59-70. In: Proceedings of the Florida Beef Cattle Short Course. Gainesville.

- McNamee, A.; Keane, M. G.; Kenny, D. A.; Moloney, A. P.; Buckley, F. and O’ Riordan, E. G. 2015. Beef production from Holstein-Friesian, Norwegian Red × Holstein-Friesian and Jersey × Holstein-Friesian male cattle reared as bulls or steers. Livestock Science 173:95-105. https://doi.org/10.1016/j.livsci.2014.12.009

» https://doi.org/10.1016/j.livsci.2014.12.009 - Muller, L. 1987. Normas para avaliação de carcaças e concurso de carcaça de novilhos. 2.ed. Imprensa Universitária, Santa Maria.

- NRC - National Research Council. 2000. Nutrient requirements of beef cattle. 7th ed. National Academies Press, Washington, D.C.

- Pacheco, P. S.; Pascoal, L. L.; Restle, J.; Vaz, F. N.; Arboitte, M. Z.; Vaz, R. Z.; Santos, J. P. A. and Oliveira, T. M. L. 2014. Risk assessment of finishing beef cattle in feedlot: Slaughter weights and correlation amongst input variables. Revista Brasileira de Zootecnia 43:92-99. https://doi.org/10.1590/S1516-35982014000200007

» https://doi.org/10.1590/S1516-35982014000200007 - Paris, W.; Santos, P. V.; Menezes, L. F. G.; Kuss, F.; Silveira, M. F.; Boito, B.; Venturini, T. and Stanqueviski, F. 2015. Quantitative carcass traits of Holstein calves, finished in different systems and slaughter weights. Ciência Rural 45:505-511. https://doi.org/10.1590/0103-8478cr20141178

» https://doi.org/10.1590/0103-8478cr20141178 - Pitchford, W. S.; Deland, M. P. B.; Siebert, B. D.; Malau-Aduli, A. E. O. and Bottema, C. D. K. 2002. Genetic variation in fatness and fatty acid composition of crossbred cattle. Journal of Animal Science 80:2825-2832. https://doi.org/10.2527/2002.80112825x

» https://doi.org/10.2527/2002.80112825x - Prado, I. N.; Passetti, R. A. C.; Rivaroli, D. C.; Ornaghi, M. G.; Souza, K. A.; Carvalho, C. B.; Perotto, D. and Moletta, J. L. 2015. Carcass composition and cuts of bulls and steers fed with three concentrate levels in the diets. Asian-Australasian Journal of Animal Sciences 28:1309-1316. https://doi.org/10.5713/ajas.15.0021

» https://doi.org/10.5713/ajas.15.0021 - Purchas, R. W.; Burnham, D. L. and Morris, S. T. 2002. Effects of growth potential and growth path on tenderness of beef longissimus muscle from bulls and steers. Journal of Animal Science 80:3211-3221. https://doi.org/10.2527/2002.80123211x

» https://doi.org/10.2527/2002.80123211x - Sañudo, C.; Macie, E. S.; Olleta, J. L.; Villarroel, M.; Panea, B. and Albertí, P. 2004. The effects of slaughter weight, breed type and ageing time on beef meat quality using two different texture devices. Meat Science 66:925-932. https://doi.org/10.1016/j.meatsci.2003.08.005

» https://doi.org/10.1016/j.meatsci.2003.08.005 - Senger, C. C. D.; Kozloski, G. V.; Bonnecarrère Sanchez, L. M.; Mesquita, F. R.; Alves, T. P. and Castagnino, D. S. 2008. Evaluation of autoclave procedures for fibre analysis in forage and concentrate feedstuffs. Animal Feed Science and Technology 146:169-174. https://doi.org/10.1016/j.anifeedsci.2007.12.008

» https://doi.org/10.1016/j.anifeedsci.2007.12.008 - Tilley, J. M. A. and Terry, R. A. 1963. A two‐stage technique for the in vitro digestion of forage crops. Grass and Forage Science 18:104-111. https://doi.org/10.1111/j.1365-2494.1963.tb00335.x

» https://doi.org/10.1111/j.1365-2494.1963.tb00335.x - Van Soest, P. J.; Robertson, J. B. and Lewis, B. A. 1991. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. Journal of Dairy Science 74:3583-3597. https://doi.org/10.3168/jds.S0022-0302(91)78551-2

» https://doi.org/10.3168/jds.S0022-0302(91)78551-2 - Van der Werf, J. H. J.; Van der Waaij, L. H.; Groen, A. F. and De Jong, G. 1998. An index for beef and veal characteristics in dairy cattle based on carcass traits. Livestock Production Science 54:11-20. https://doi.org/10.1016/S0301-6226(97)00167-X

» https://doi.org/10.1016/S0301-6226(97)00167-X - Waritthitham, A.; Lambertz, C.; Langholz, H. J.; Wicke, M. and Gauly, M. 2010. Assessment of beef production from Brahman × Thai native and Charolais × Thai native crossbred bulls slaughtered at different weights. II: Meat quality. Meat Science 85:196-200. https://doi.org/10.1016/j.meatsci.2009.12.025

» https://doi.org/10.1016/j.meatsci.2009.12.025

Publication Dates

-

Publication in this collection

25 Nov 2020 -

Date of issue

2020

History

-

Received

21 Apr 2020 -

Accepted

14 Oct 2020