ABSTRACT.

Microfiber fabrics are more efficiency in retaining fine-particles that increase the variation in in situ degradability. The aim of this was to examine the performance of in situ bags made from different microfiber fabric for meeting the required specification and their ruminal degradability compared with standard Ankom in situ bags. Four fabrics were manufactured using polyester microfiber with 1.04 denier, weft yarn counts (150 and 300), weft density (22 and 28 picks / inch), plain 1/1 textile structure. Physical and mechanical properties of manufactured fabrics were measured before and after incubation. Ruminal degradability was measured for three feedstuffs (soybean meal, wheat bran and berseem hay) using three rumen-fistulated rams as a replicates after 24 and 48 hours. Fabric's pore size was significantly decreased as either yarn weft count or density increased. Yarn weft count had a significant effect on all fabric's properties. Air permeability was significantly decreased as fabric's weft yarn count increased. Sample (1) meet the specific requirements for in situ bags and showed the nearest degradability values to those observed using Ankom bags for all feedstuffs in most incubation times. Microfiberin situ bags could be used in in situ ruminal degradation trials to reduce the variation in results due to the present of the fine particles.

Keywords:

bags; fabric; feedstuffs; incubation; nutrient; pore size

Introduction

In situ technique is one of the most important methods used for feed evaluation. It could provide useful information about the rate and extent of nutrient degradation inside the rumen, which enables the formulation of a synchronous least cost rations for better feed utilization (Bogoro, Kalla, & Gaiya, 2006Bogoro, S., Kalla, D. J. U., & Gaiya, O. (2006). Effect of positioning of feed samples in two segments of the rumen on in-situ degradability of feed stuffs. Pakistan Journal of Nutrition, 5(2), 152-155. doi: 10.3923/pjn.2006.152.155

https://doi.org/10.3923/pjn.2006.152.155...

; Khadem, Pahlavan, Afzalzadeh, & Rezaeian, 2007Khadem, A. A., Pahlavan, M., Afzalzadeh, A., & Rezaeian, M. (2007). Effects of live yeast saccharomyces cerevisiae on fermentation parameters and microbial populations of rumen, Total tract digestibility of diet nutrients and on the in situ degradability of alfalfa hay in iranianchall sheep. Pakistan Journal of Biological Sciences, 10, 590-597.; Aboameret al., 2015Aboamer, A. A., El-sayed, H. M., Abo el-nor, S. A. H., Khorsed, M. M., Kholif, A. M., & Saleh, H. M. (2015). Synchronous least-cost ration formulation for lactating barki ewes using nonlinear programming. Journal of Animal Production Advances, 5(8), 733-746. doi: 10.5455/japa.20150816041529

https://doi.org/10.5455/japa.20150816041...

; Aboameret al., 2017Aboamer, A. A., Khattab, M. S. A., Abo el-nor, S. A. H., Saleh, H. M., Kholif, A. M., & Khattab, I. M. (2017). A study of nutrient digestibility, milk production and performance of lactating barki ewes fed synchronous least cost ration. International Journal of Dairy Science,12. 114-121. doi: 10.3923/ijds.2017.114.121

https://doi.org/10.3923/ijds.2017.114.12...

).

Several works evaluated in situ bags made from different textile materials (Valente, Detmann, & Sampaio, 2015Valente, T. N. P., Detmann, E., & Sampaio, C. B. (2015). Review: Recent advances in evaluation of bags made from different textiles used in situ ruminal degradation. Canadian Journal of Animal Science, 95(4), 493-498. doi: 10.4141/cjas-2015-100

https://doi.org/10.4141/cjas-2015-100...

). In addition, a standard protocol has been introduced by the Nordic feed evaluation systemrecommended to use polyester bags with 38 μm of pore size (Saatifil PES 38/31, manufactured by Saatitech, Como, Italy). However, the mostly used bags manufactured by ANKOM Technologyhave 50 ± 10 µm porosity and are available with two sizes (5 cm x 10 cm-R510 and 10 cm x 20 cm-R1020) for concentrates and roughage, respectively.

Since, in situdegradability depends mainly on the efflux of digested feed particles from the pores of the bags, the results were highly affected by bags,pore size, cloth type, weave pattern and bag dimensions (Adesogan, 2005Adesogan, A. T. (2005). Effect of bag type on the apparent digestibility of feeds in ANKOM Daisy II incubators. Animal Feed Science and Technology, 119(3-4), 333-344. doi: 10.1016/j.anifeedsci.2004.09.012

https://doi.org/10.1016/j.anifeedsci.200...

; Valente et al.,2011Valente, T. N. P., Detmann, E., Queiroza, A. C. D. E., Valadares Filho, S. D. E. C., Gomes, D. I., & Figueiras, J. F. (2011). Evaluation of ruminal degradation profiles of forages using bags made from different textiles. RevistaBrasileira de Zootecnia, 40(11), 2565-2573. doi: 10.1590/s1516-35982011001100039

https://doi.org/10.1590/s1516-3598201100...

; Valente et al., 2015Valente, T. N. P., Detmann, E., & Sampaio, C. B. (2015). Review: Recent advances in evaluation of bags made from different textiles used in situ ruminal degradation. Canadian Journal of Animal Science, 95(4), 493-498. doi: 10.4141/cjas-2015-100

https://doi.org/10.4141/cjas-2015-100...

). The most effect is the overestimation of feed degradability which was observed due to loss of undigested fine particles from bags pores (Mabjeesh et al., 2000Mabjeesh, S. J., Cohen, M., & Arieli, A. (2000). In vitro methods for measuring the dry matter digestibility of ruminant feedstuffs: Comparison of methods and inoculum source. Journal of Dairy Science, 83(10), 2289-2294. doi: 10.3168/jds.s0022-0302(00)75115-0

https://doi.org/10.3168/jds.s0022-0302(0...

; Wilman & Adesogan, 2000Wilman, D., & Adesogan, A. A. (2000). Comparison of filter bag methods with conventional tube methods of determining the in vitro digestibility of forages. Animal Feed Science and Technology, 84(1-2), 33-47. doi: 10.1016/s0377-8401(00)00110-3

https://doi.org/10.1016/s0377-8401(00)00...

).

Fabrics pores include the spaces (pores) between fibers in the yarns and also the space between two yarns (Babaarslan&Haciogullari, 2013Babaarslan, O., &Haciogullari, S. Ö. (2013). Effect of fibre cross-sectional shape on the properties of POY continuous filaments yarns. Fibers Polymers, 14, 146-151. doi: 10.1007/s12221-013-0146-z

https://doi.org/10.1007/s12221-013-0146-...

).Number of parameters affects the pores of the fabrics. Both yarn density and yarn thickness are factors affecting the dimensions of the pores (spaces) between yarns. There is an inversely proportion between the yarn density and dimensions of pores. Increasing yarn density producesa smaller dimension of fabric pores (Babaarslan & Haciogullari, 2013). All these properties make the filtration efficiency of fabrics made from microfiber higher than traditional fabrics.

Microfiber fabrics arestrongerand durable compared with other fabrics of similar weight. In addition, microfibers are non-electrostatic, super-absorbent, absorbing over seven times their weight in water and they dry in one-third of the time of ordinary fibers (Babaarslan, 2013Babaarslan, O., &Haciogullari, S. Ö. (2013). Effect of fibre cross-sectional shape on the properties of POY continuous filaments yarns. Fibers Polymers, 14, 146-151. doi: 10.1007/s12221-013-0146-z

https://doi.org/10.1007/s12221-013-0146-...

).

There is no previous research studied the performance of in situ bags made from microfiber fabrics and their effect on ruminal degradability of feeds. The aim of this work was to: 1) manufacture in situ bags using polyester microfibers with two different variables employed, weft yarn count (150 and 300 deniers per filament) and density (22 and 28 picks / inch), 2) investigate fabric ability to meet performance requirements before and after incubation in rumen, and 3) compare the dry matter digestibility values of some dairy feedstuffs using the manufactured bags with Ankom in situ bags (ANKOM SKU: R510, and ANKOM SKU: R1020).

Material and methods

Manufacturing of polyester microfibers bags

An innovative idea was done, andits main purposewasproviding a scientific study for the production of these textile bags at the local level. In this study, polyester microfiber with 1.04 denier, warp count (150) denier, weft yarn counts (150 and 300 Deniers), warp density (30 picks / inch), weft density (22 and 28 picks / inch), plain 1/1 textile structure were used to manufacture four samples of fabric. The weft yarn count of samples1 and 2, and 3 and 4were 150 and 300 deniers, respectively. While, the weft density of the samples 1 and 3, and 2 and 4were 22 and 28 (picks/inch), respectively, as shown in Table 1.

Laboratory tests

Laboratory tests were done to examine the performance of the manufactured samples for meeting the required specification of in situ bags before and after incubation.

Two measurements of mechanical properties were conducted using universal testing machine, tensile strength was applied according to Standard Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method) using ASTM D5035; and tear strength was applied according to Standard Test Method for Tearing Strength of Fabrics by the Tongue (Single Rip) Procedure (Constant-Rate-of-Extension Tensile Testing Machine) using ASTM D2261, while air permeability was performed according to Standard Test Method for Air Permeability of Textile Fabrics using ASTM D737. Three replicates were measured for two laboratory tests:Breaking load and Elongation and Air permeability in both directions warp and weft and the average values were taken, while in tear strength tests three replicates were measured, the five highest peak forces for each replicate were calculated and the average values for the fifteen reading were calculated.

In vitro trial

The nylon bag technique as described by (Ørskov, Hovell, & Mould, 1980Ørskov, E. R., Hovell, F. D., & Mould, F. (1980). The use of the nylon bag technique for the evaluation of feedstuffs. Tropical Animal Production, 5(3), 195-213.), was applied for degradability coefficients determination to study the performance of manufactured bags in field. In situ trails were conducted using three of cannulated rams (50.60 ± 3.05 kgof body weight) at the Marryot Research Station, Desert Research Centre, Ministry of Agriculture, 35 km south of Alexandria, Egypt. Rams were fed at maintenance level 40:60 concentrate to roughage as replicates. The dry matter degradability was determined for three feedstuffs; two sources of concentrates (soybean meal and wheat bran) and one roughage source (berseem hay). Feed samples were grinded to 2 mm before incubation in the rumen for 24 and 48 hrs. Feed samples (1.5 - 2 and 3.5 - 4 g for concentrates and roughages, respectively) were inserted into a previously weighted, clean, dry and numbered bag, then, incubated in the rumen at 1 hour after the morning feeding. After incubation, the bags with residues were taken out of the rumen, dipped immediately into cold water to stop microbial activity, then washed under running cold water until the water was clear, after which the bags were drained, dried for 72h at 60°C, cooled in a desiccator and weighed. The solubility or washing loss at 0 hour was defined as weight loss after soaking the bags, with the substrate, for 1 hour in water at 38°C then washing and drying in a similar way. The ruminal disappearance rate of tested feed at each individual incubation time was calculated as the difference between the contents in the initial samples and the residues remaining after incubation in the rumen and expressed as a percentage of the content of the initial sample. In order to study the effect of incubation and frequently drying and washing on the physical and mechanical properties of the bags, new bag was used for each feed sample.

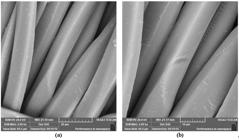

Scanning electron microscope (SEM)

SEM was done for samples using a scanning electron probe micro analyzer (type T-scan-Czech Republic). The sample was cut at sizeabout 1*1 cm, sample sections were stainedwith Chrome in an individual instrument. The SEM samples were labeled using indelible marker in order to be identified, and then the specimens were put inside the scanning electron microscope to be measured. The surface morphologies for samples were imaged at differentmagnifications (2000x, 3000x), using 5kV accelerating voltage.

Statistical analysis

Results were reported based on the mean values of observation with their standard error of means. ANOVA Two-way Repeated Measurements were used to statistically analyze the differences in fabrics' physical and mechanical properties before and after incubation using SPSS, version 24 (SPSS, 2016SPSS Inc. (2016). IBM SPSS Statistics for Windows, Version 24.0. Armonk, NY: IBM Corp.). Differences in in situ ruminal degradability were statistically analyzed using One-way ANOVA and means compared using Tukey HSD test. The level of significance was at P value=0.05.

Results

Physical and mechanical properties of manufactured fabrics

Table 1 represents the constructional parameters of the manufactured samples. Increase yarn weft count produce higher thickness fabrics. Sample 4 had the highest fabric thickness (0.29, mm). The physical and mechanical properties of the manufactured samples before and after incubation in the rumen are presented in table 2. Data show that, manufactured in situ bags had a wide range for fabrics pore size (30.0 - 72.7, µm). Fabric's pore size was significantly affected by both yarn weft count and density (p < 0.001) with no significant interaction (p = 0.089). Fabric’s pore size was decreased as increasing either weft yarn count or density. Sample 4 had the lowest fabric pore size. In contrast, sample 1 had largest pore size (72.7 µm) with lowest weft count and density.

In general, the effect of yarn weft count was significant for all fabric's properties. Tensile strength for both weft and warp directions were increased as increasing yarn weft count, while the rate of increase was greater for weft direction. However, their effect on tensile elongation differed. As yarn weft count increased, tensile elongation was increased for the warp direction (p < 0.05). However, it decreased at weft direction. Also, tear strength was affected by increasing weft count. It was decreased at the warp direction, while markedly increased at the weft direction (p < 0.001). Both air and water permeability were decreased as increasing yarn weft count (p < 0.001). However, the rate of decay of air permeability was markedly higher than of water permeability.

On the other hand, both tensile strength and elongation at the weft direction were significantly improved as increasing yarn weft density. However, at the warp direction, the tear strength was decreased. Furthermore, both air and water permeability were remarkably decreased by increasing yarn weft density (p < 0.001).

In general, all measured fabric’s properties were significantly affected by incubation in the rumen (p < 0.02). As shown in Table 2, incubation had a negative effect on the tensile strength of sample 2 for both weft and warp directions, while other samples were not affected.

In addition, tensile elongation for warp direction was increased after rumen incubation for all samples. Also, incubation was significantly affected by fabric’s tear strength for weft direction. The weft tear strength was significantly increased for sample 2 while, decreased for sample (4).

The air permeability of sample 2 was dramatically decreased after incubation (p < 0.05). However, other samples did not affected.

In situ DM degradability coefficients

Table 3 represents the in situ DM degradability coefficients for the some commonly used feedstuffs using both manufactured in situ bags and standard Ankom bags. For all feedstuff, no significant difference was observed for either DM washing loss or ruminal degradability after 24 hours between sample 1and Ankom bags. However, sample 1 had a slightly higher value for in situ ruminal degradability after 48 hours compared with Ankom bags.

Sample 4 had the lowest ruminal degradability for all feedstuffs. Samples 2 and 3 had approximately the same values of ruminal DM degradability for all feedstuffs, but they were significantly lower than observed for Ankom bags.

Scanning electron microscope (SEM)

SEM was done for sample 1 before and after incubation, it was magnified in 2000 and 3000 X. Figure 1 show number of fibers with smooth surface before incubation and after washing. Figure 2 show the sample after incubation and the feedstuff particles on the surface of the fabric due to exposing the sample in the incubation conditions (oven- humidity- temperature-strength).

Discussion

The obtained results show that, fabric thickness was increased as yarn weft count increased. Sample (1) had the most suitable fabric thickness. The yarn weft count and the weft density for sample (1) were 150 deniers and 22 picks / inch, respectively. Previous work conducted by (Al-ansary, 2012Al-ansary, M. A. R. (2012). The influence of number of filaments on physical and mechanical characteristics of polyester woven fabrics. Life Science Journal, 9(3), 79-83, 2012.

https://doi.org/2012...

) reported that, microfiber fabrics are more thickness than traditional fabrics due to increase the number of filaments per yarn. The total number of in situ bags incubated in the rumen at one time is limited which make it difficult to be removed, so increasing the thickness of in situ bags could make the removal of bags from the rumen more difficult and then decreasing the number of bags incubated in rumen at one time could be required.

On the other hand, fabrics’ pore size had been decreased as increasing both yarn weft count and density. Manufactured in situ bags samples2 and 3 met the recommend pore size, while sample 2had lower pore size than recommended. Although, the fabric pore size of sample 1 was higher than samples 2 and 3, it produced the most nearest values of ruminal degradability to that observed using the standard Ankom bags. In addition, samples (2 and 3) had pore size within the recommended range (42.1 and 53.5µm, respectively), but they underestimate the ruminal degradability. So, it could be suggested that, the recommended range might be slightly increased when microfiber in situ bags is used. That may be due special characteristics of the microfiber fabrics as larger surface area, spaces between filaments, and thickness. Also, lower air and water permeability as increase fabric thickness might provide a stable fermentation condition, while reduce the finer particles escaped from in situ bags. The washing loss after zero hour of incubation represents the rapidly or instantaneously degraded fraction (Aboamer et al., 2017Aboamer, A. A., Khattab, M. S. A., Abo el-nor, S. A. H., Saleh, H. M., Kholif, A. M., & Khattab, I. M. (2017). A study of nutrient digestibility, milk production and performance of lactating barki ewes fed synchronous least cost ration. International Journal of Dairy Science,12. 114-121. doi: 10.3923/ijds.2017.114.121

https://doi.org/10.3923/ijds.2017.114.12...

) that is highly affected with feed particle size and fabric’s pores (Ørskov et al., 1980Ørskov, E. R., Hovell, F. D., & Mould, F. (1980). The use of the nylon bag technique for the evaluation of feedstuffs. Tropical Animal Production, 5(3), 195-213.). Adesogan (2005Adesogan, A. T. (2005). Effect of bag type on the apparent digestibility of feeds in ANKOM Daisy II incubators. Animal Feed Science and Technology, 119(3-4), 333-344. doi: 10.1016/j.anifeedsci.2004.09.012

https://doi.org/10.1016/j.anifeedsci.200...

) observed an underestimation of in situdegradability due to the fine particles that pass through bags’ pores. Kuwahara, Souza, Ferreira, Costa, and Meirelles (2016Kuwahara, F. A., Souza, G. P., Ferreira, R. P., Costa, C., & Meirelles, P. R. L. (2016). Evaluation in situ digestibility of alfalfa indifferent grinds and textiles. Acta Scientiarum. Animal Sciences, 38(1), 37-43. doi: 10.4025/actascianimsci.v38i1.28867

https://doi.org/10.4025/actascianimsci.v...

) reported significant differences in in situ DM degradability between samples of alfalfaground into three differentparticle size especially at the initial periods of incubation.

In contrast, sample 4 does not meet the required specifications for in situ bags. The very small pores and more fabric thickness prevent air and water from passage through fabrics. These factors might prevent the colonization and digestion of feed particles by ruminal microbes (Vanzant, Cochran, &Titgemeyer, 1998Vanzant, E. S., Cochran, R. C., & Titgemeyer, E. C. (1998). Standardization of in situ techniques for ruminant feedstuff evaluation. Journal of Animal Science, 76(10),2717-2279. doi: 10.2527/1998.76102717x

https://doi.org/10.2527/1998.76102717x...

).

On the other hand, in situ bags should withstand the incubation and laboratory conditions. Obtained results showed adverse effects on samples 2 after incubation. The weft tensile strength was significantly decreased after incubation, giving a greater possibility for losing feed particle due to fabric damage. In addition, the significant increase in the weft tear strength (32.1 vs. 60.1, N) may be due to accumulate of feed particles between the fibers of yarn which lead to a significant decrease in air permeability (17.2 vs. 7.3 cm3cm-2.sec).

Conclusion

Microfiber fabrics had a greater surface area, filtration efficiency and high ability to retain fine feed particles compared to traditional fabrics. Using microfiber in situ bags may be useful to reduce the variation in in situ results that occur due to the present of the fine particles after the grinding feeds. Manufactured microfiber in situ bag (sample 1) had the nearest degradability values to those observed using Ankom bags.

References

- Aboamer, A. A., El-sayed, H. M., Abo el-nor, S. A. H., Khorsed, M. M., Kholif, A. M., & Saleh, H. M. (2015). Synchronous least-cost ration formulation for lactating barki ewes using nonlinear programming. Journal of Animal Production Advances, 5(8), 733-746. doi: 10.5455/japa.20150816041529

» https://doi.org/10.5455/japa.20150816041529 - Aboamer, A. A., Khattab, M. S. A., Abo el-nor, S. A. H., Saleh, H. M., Kholif, A. M., & Khattab, I. M. (2017). A study of nutrient digestibility, milk production and performance of lactating barki ewes fed synchronous least cost ration. International Journal of Dairy Science,12 114-121. doi: 10.3923/ijds.2017.114.121

» https://doi.org/10.3923/ijds.2017.114.121 - Adesogan, A. T. (2005). Effect of bag type on the apparent digestibility of feeds in ANKOM Daisy II incubators. Animal Feed Science and Technology, 119(3-4), 333-344. doi: 10.1016/j.anifeedsci.2004.09.012

» https://doi.org/10.1016/j.anifeedsci.2004.09.012 - Kuwahara, F. A., Souza, G. P., Ferreira, R. P., Costa, C., & Meirelles, P. R. L. (2016). Evaluation in situ digestibility of alfalfa indifferent grinds and textiles. Acta Scientiarum. Animal Sciences, 38(1), 37-43. doi: 10.4025/actascianimsci.v38i1.28867

» https://doi.org/10.4025/actascianimsci.v38i1.28867 - Al-ansary, M. A. R. (2012). The influence of number of filaments on physical and mechanical characteristics of polyester woven fabrics. Life Science Journal, 9(3), 79-83, 2012.

» https://doi.org/2012 - Babaarslan, O., &Haciogullari, S. Ö. (2013). Effect of fibre cross-sectional shape on the properties of POY continuous filaments yarns. Fibers Polymers, 14, 146-151. doi: 10.1007/s12221-013-0146-z

» https://doi.org/10.1007/s12221-013-0146-z - Bogoro, S., Kalla, D. J. U., & Gaiya, O. (2006). Effect of positioning of feed samples in two segments of the rumen on in-situ degradability of feed stuffs. Pakistan Journal of Nutrition, 5(2), 152-155. doi: 10.3923/pjn.2006.152.155

» https://doi.org/10.3923/pjn.2006.152.155 - Khadem, A. A., Pahlavan, M., Afzalzadeh, A., & Rezaeian, M. (2007). Effects of live yeast saccharomyces cerevisiae on fermentation parameters and microbial populations of rumen, Total tract digestibility of diet nutrients and on the in situ degradability of alfalfa hay in iranianchall sheep. Pakistan Journal of Biological Sciences, 10, 590-597.

- Mabjeesh, S. J., Cohen, M., & Arieli, A. (2000). In vitro methods for measuring the dry matter digestibility of ruminant feedstuffs: Comparison of methods and inoculum source. Journal of Dairy Science, 83(10), 2289-2294. doi: 10.3168/jds.s0022-0302(00)75115-0

» https://doi.org/10.3168/jds.s0022-0302(00)75115-0 - Ørskov, E. R., Hovell, F. D., & Mould, F. (1980). The use of the nylon bag technique for the evaluation of feedstuffs. Tropical Animal Production, 5(3), 195-213.

- SPSS Inc. (2016). IBM SPSS Statistics for Windows, Version 24.0 Armonk, NY: IBM Corp.

- Valente, T. N. P., Detmann, E., Queiroza, A. C. D. E., Valadares Filho, S. D. E. C., Gomes, D. I., & Figueiras, J. F. (2011). Evaluation of ruminal degradation profiles of forages using bags made from different textiles. RevistaBrasileira de Zootecnia, 40(11), 2565-2573. doi: 10.1590/s1516-35982011001100039

» https://doi.org/10.1590/s1516-35982011001100039 - Valente, T. N. P., Detmann, E., & Sampaio, C. B. (2015). Review: Recent advances in evaluation of bags made from different textiles used in situ ruminal degradation. Canadian Journal of Animal Science, 95(4), 493-498. doi: 10.4141/cjas-2015-100

» https://doi.org/10.4141/cjas-2015-100 - Vanzant, E. S., Cochran, R. C., & Titgemeyer, E. C. (1998). Standardization of in situ techniques for ruminant feedstuff evaluation. Journal of Animal Science, 76(10),2717-2279. doi: 10.2527/1998.76102717x

» https://doi.org/10.2527/1998.76102717x - Wilman, D., & Adesogan, A. A. (2000). Comparison of filter bag methods with conventional tube methods of determining the in vitro digestibility of forages. Animal Feed Science and Technology, 84(1-2), 33-47. doi: 10.1016/s0377-8401(00)00110-3

» https://doi.org/10.1016/s0377-8401(00)00110-3

Publication Dates

-

Publication in this collection

18 May 2020 -

Date of issue

2020

History

-

Received

25 June 2019 -

Accepted

15 July 2019